Medium trace element soil conditioner and preparation method thereof

A technology of soil conditioner and medium and trace elements, applied in application, organic fertilizer, inorganic fertilizer, etc., can solve the problems of geographical restrictions, ecological damage, environmental pollution, etc., and achieve the effect of reducing application amount, lasting fertilizer effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

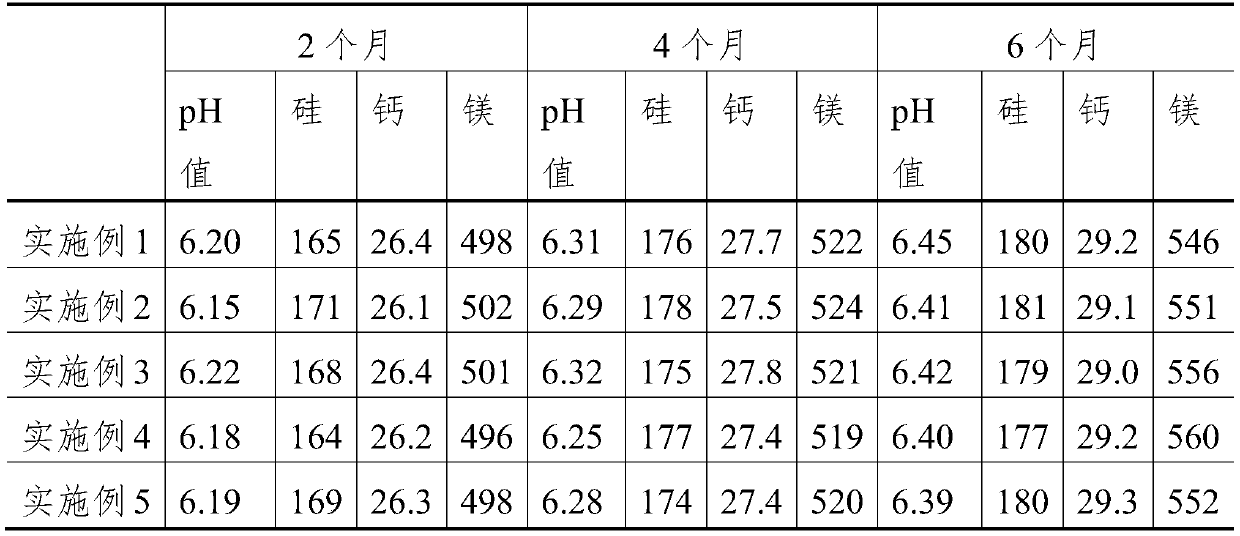

Examples

Embodiment 1

[0028] The preparation method of the middle and trace element soil conditioner of the present embodiment comprises:

[0029] a Raw materials: weigh 45 parts of oyster shells, 20 parts of silicon dioxide, 20 parts of lightly burned magnesium powder and 8 parts of bentonite;

[0030] b Crushing, grinding, pelleting, drying: Mix and crush the raw materials weighed in step a, grind to 160 mesh, sieve and add water to form balls below 8mm and dry

[0031] c Calcination: Rotate the raw material balls in step b to a rotary calciner at 1300°C under the condition of 0.95 Pa, and calcinate for 40 minutes to obtain clinker;

[0032] d water quenching / activation: the clinker in step c is water quenched to obtain a solid particle product and dried

[0033] e Grinding: Grinding the solid particle product in step d to 120 mesh and sieving to obtain a powdery microelement soil conditioner;

[0034] f Granulation: Add 8 parts of attapulgite powder, 2 parts of magnesium sulfate, 1 part of sod...

Embodiment 2

[0036] The preparation method of the middle and trace element soil conditioner of the present embodiment comprises:

[0037] a Raw materials: weigh 60 parts of oyster shells, 10 parts of river sand, 30 parts of lightly burned magnesium powder and 9 parts of bentonite;

[0038] b Crushing, grinding, pelleting, drying: Mix and crush the raw materials weighed in step a, grind to 120 mesh, sieve and add water to form balls below 8mm and dry

[0039] c Calcination: Calcining the raw material balls in step b at 1200°C in a rotary calciner at 0.95 Pa for 35 minutes to obtain clinker;

[0040] d water quenching / activation: the clinker in step c is water quenched to obtain a solid particle product and dried

[0041] e Grinding: Grinding the solid particle product in step d to 200 mesh and sieving to obtain a powdery microelement soil conditioner;

[0042] f Granulation: Add 6 parts of attapulgite powder, 2.5 parts of magnesium sulfate, 2 parts of sodium hydroxide, 3 parts of sugar et...

Embodiment 3

[0044] The preparation method of the middle and trace element soil conditioner of the present embodiment comprises:

[0045] a Raw materials: weigh 70 parts of oyster shells, 15 parts of quartz, 10 parts of lightly burned magnesium powder and 10 parts of bentonite;

[0046] b Crushing, grinding, pelleting, drying: Mix and crush the raw materials weighed in step a, grind to 140 mesh, sieve, add water to form balls below 8mm and dry

[0047] c Calcination: Rotate the raw material balls in step b to a rotary calciner at 1350°C under the condition of 0.95Pa, and calcinate for 30 minutes to obtain clinker;

[0048] d water quenching / activation: water quenching the clinker in step c to obtain a solid particle product;

[0049] e Grinding: Grinding the solid particle product in step d to 160 mesh and sieving to obtain a powdery microelement soil conditioner;

[0050] f Granulation: Add 12 parts of attapulgite powder, 1 part of magnesium sulfate, 0.5 part of sodium hydroxide, 4 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com