Preparation method of environment-friendly functional amphoteric polymeric flocculant

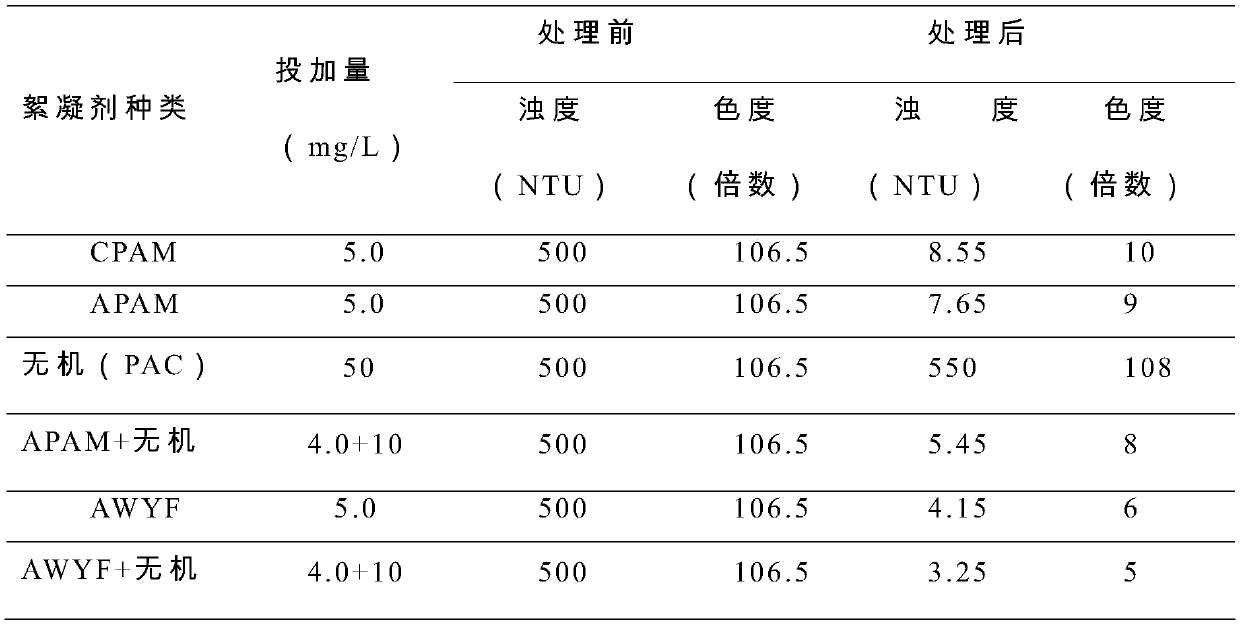

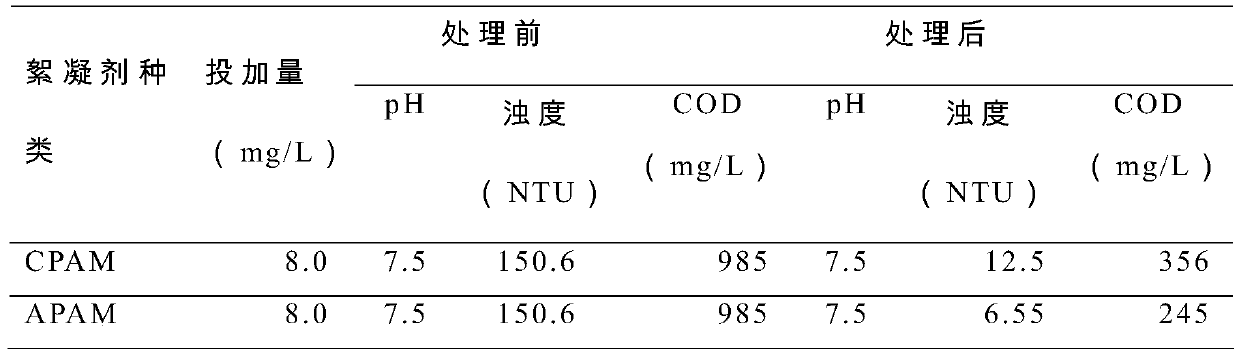

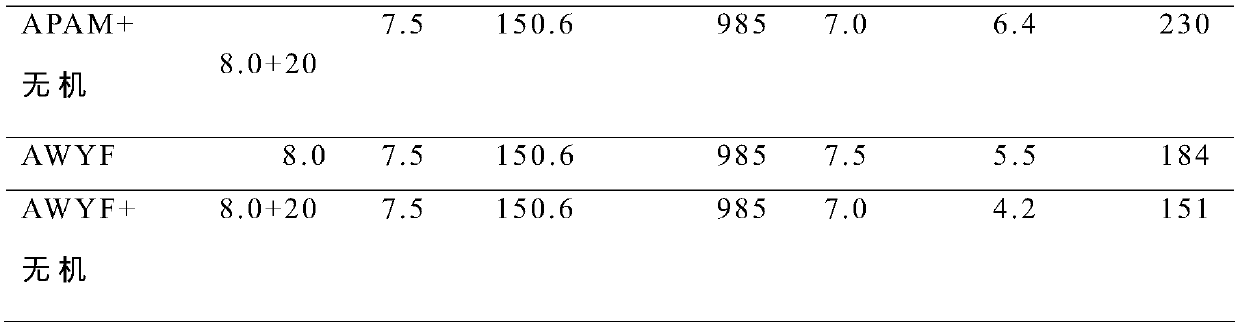

An amphoteric polymer and functional technology, applied in the field of water treatment, can solve the problems of difficult product degradation, narrow application range, and secondary pollution, and achieve good flocculation effect, low price, and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A preparation method of an environmental-friendly functional amphoteric polymer flocculant, the preparation method comprising the following steps:

[0052] 1) Prepare materials: pulp powder, absolute ethanol, 30% sodium hydroxide solution, etherification agent, initiator, acrylamide, aldehydes, amines, distilled water according to the mass ratio 1: (1.15-1.75): (1.5- 2.5): (0.3-0.6): (0.12-0.18): (1.6-3.1): (0.9-1.5): (1.5-2.3): 100 for material preparation;

[0053] 2) Dispersion, alkalization, and etherification of pulp powder: mix pulp powder with absolute ethanol, mechanically stir, and ultrasonically stir to fully disperse pulp powder; add 30% sodium hydroxide solution, ultrasonically stir, and alkalize; add etherification Agent and distilled water, etherification reaction, obtain carboxylation product;

[0054] 3) Graft copolymerization reaction: heat up the carboxylated product obtained in 2), add an initiator and acrylamide, pass through nitrogen protection, ke...

Embodiment 1

[0070] An environmentally friendly functional amphoteric polymer flocculant, prepared by the following method:

[0071] Take 5g of pulp powder, put it into a four-necked flask, add 6ml of absolute ethanol, place it in a water bath with ultrasonic, turn on the mechanical stirring for 10 minutes, and the stirring speed is 250r / min; then stop the mechanical stirring, adjust the ultrasonic frequency to 30KHZ, power 450W, ultrasonic vibration for 30min to fully disperse the pulp powder; stop the vibration, raise the temperature to 40°C, add 10ml of 30% sodium hydroxide solution, ultrasonic vibration for 30min, frequency 25KHZ, power 425W, carry out alkalization treatment; stop vibration, add 2.1 g etherification agent and 10ml distilled water, mechanically stirred for 30min, stirring speed 250r / min; then stop mechanical stirring, adjust ultrasonic frequency to 25KHZ, power 425W, vibrate and stir for 1h, obtain carboxylated product after etherification reaction; stop vibrating, add 1...

Embodiment 2

[0074] An environmentally friendly functional amphoteric polymer flocculant, prepared by the following method:

[0075] Take 5g of pulp powder, put it into a four-neck flask, add 6ml of absolute ethanol, place it in a water bath with ultrasonic, turn on the mechanical stirring for 5 minutes, and the stirring speed is 250r / min; then stop the mechanical stirring, adjust the ultrasonic frequency to 35KHZ, power 480W, ultrasonic vibration for 35min to fully disperse the pulp powder; stop the vibration, raise the temperature to 40°C, add 10ml of 30% sodium hydroxide solution, ultrasonic vibration for 35min, frequency 30KHZ, power 450W, carry out alkalization treatment; stop vibration, add 2.0 g etherification agent and 10ml distilled water, mechanically stirred for 20min, stirring speed 250r / min; then stop mechanical stirring, adjust ultrasonic frequency 30KHZ, power 450W, vibrate and stir for 1h, after etherification reaction, carboxylated product is obtained; stop vibrating, add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com