Quantitative dissolution and uniform mixing addition system of flocculation agent

A uniform mixing and medicament technology, applied in the direction of dissolution, mixer, settling tank, etc., can solve the problem of small turbulent flow, and achieve the effect of fast settling speed, reasonable system structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

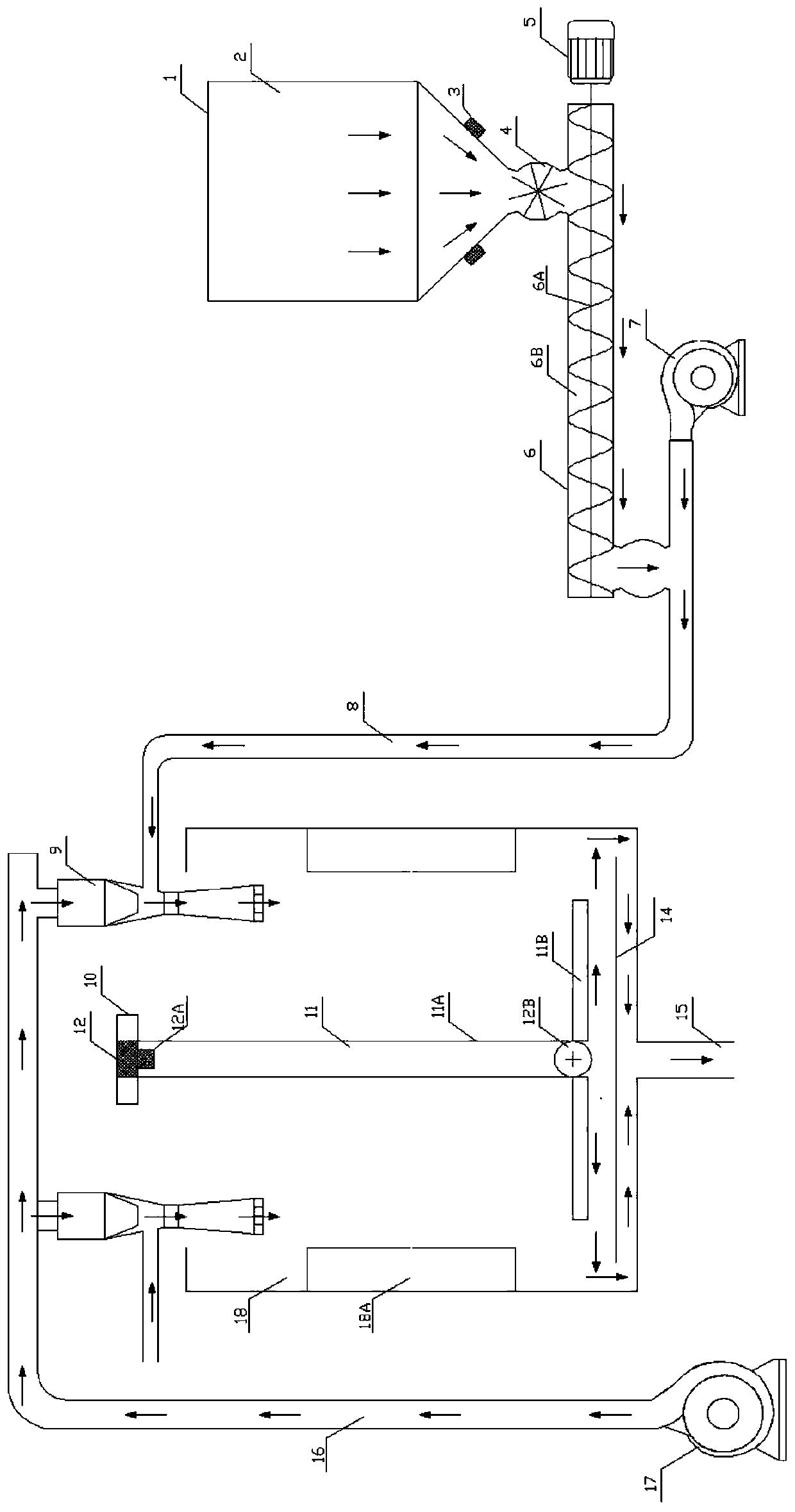

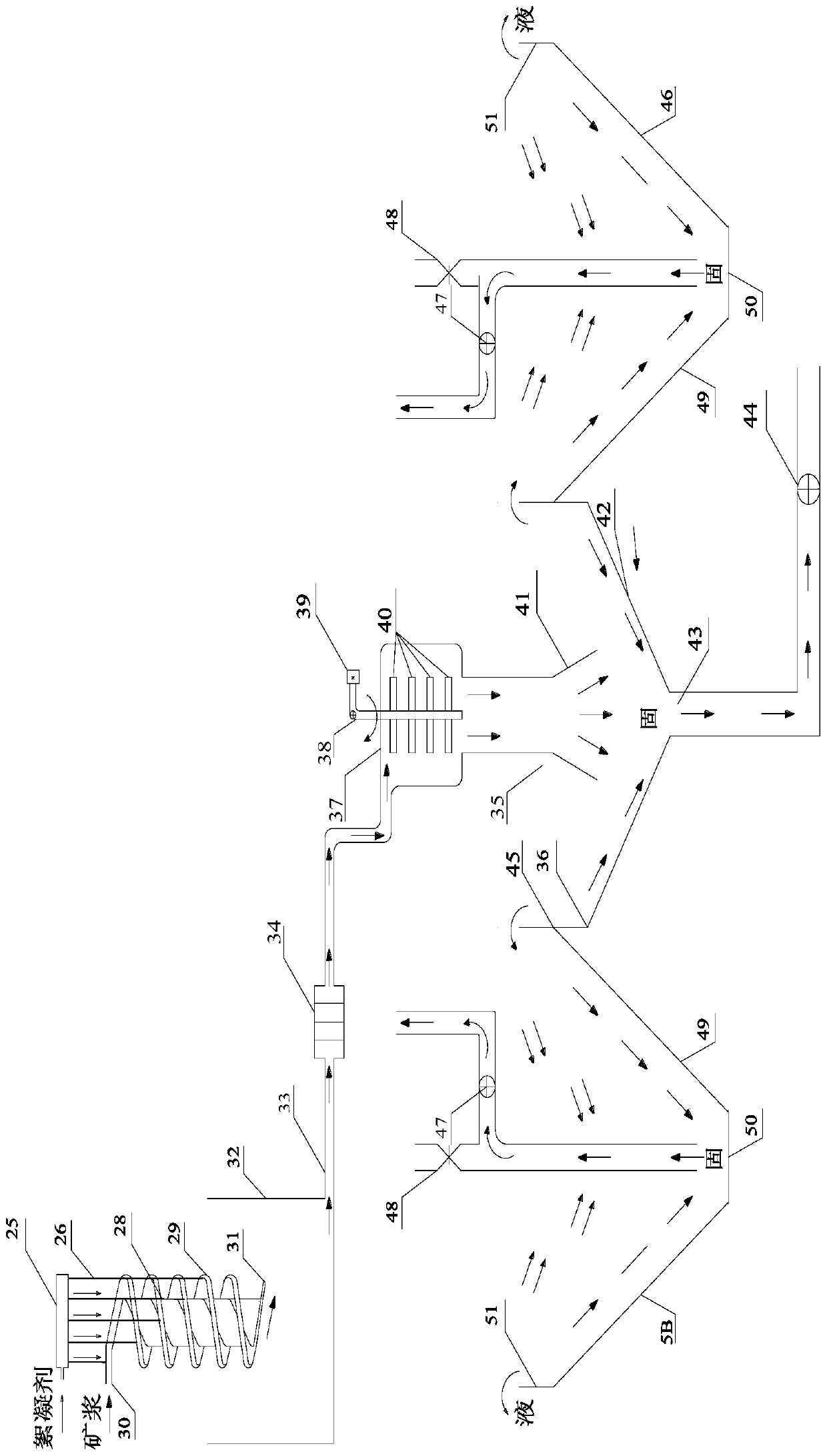

[0049] For ease of understanding, combined here Figure 1-8 , the specific embodiments of the present invention are further described as follows:

[0050] The specific components of the present invention are divided into medicament storage system (A), medicament quantitative delivery and addition system (B), medicament efficient dispersion system (C), PLC intelligent control system (D), ore pulp and medicament mixing system (E) And the slime water concentration settling system (F). Describe them one by one below:

[0051] Medicament storage system (A), the storage system includes sequentially connected storage bins (2), electromagnetic exciters (3), and star discharge valves (4); the upper part of the storage bin is barrel-shaped, and the lower part is Inverted cone shape, the top of the storage bin is an open feed inlet, and the bottom is provided with a discharge port. Electromagnetic exciters (3) are installed on both sides of the inverted cone at the lower part of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com