Section steel manufacturing system and method based on BIM and CAM technologies

A technology for manufacturing systems and profiles, applied in the direction of instruments, data processing applications, office automation, etc., can solve the problems of cumbersome tasks, processing preparation time exceeding processing time, and information disconnection, etc., and achieve the effect of reasonable system structure and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific diagrams.

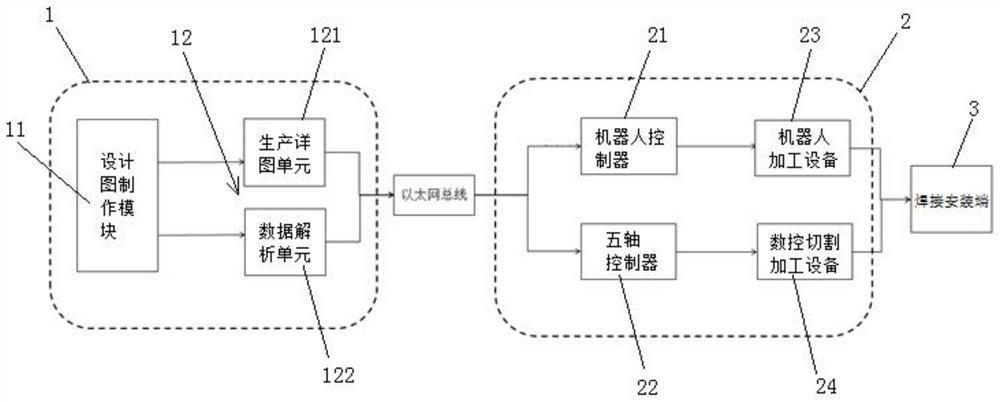

[0037] The first embodiment of the present invention discloses a profile manufacturing system based on BIM+CAM technology, such as figure 2 and image 3 As shown, it includes information transmission between BIM design terminal 1 and CAM production terminal 2. BIM design terminal 1 includes a connected design drawing production module 11 and a profile software processing module 12. CAM production terminal 2 includes interconnected controllers and processing equipment. The profile software processing module 12 is connected to the controller through the Ethernet bus, and the processing equipment is connected to the welding installation end 3 .

[0038] Specifically, the design diagram making module 11 includes TEKLA software, Revit software and Rhino software, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com