Sun-screening composition containing sucrose acetate iso-butyrate and preparation method of sun-screening composition containing sucrose acetate iso-butyrate

A technology of isobutyric acetate and sucrose ester, which is applied in the directions of medical preparations containing active ingredients, preparations for skin care, pharmaceutical formulations, etc., can solve the problem of not finding sucrose acetate isobutyrate, etc., and achieves adaptation to large-scale industrialization. Production, not easy to aggregate and precipitate, and reduce the effect of density difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

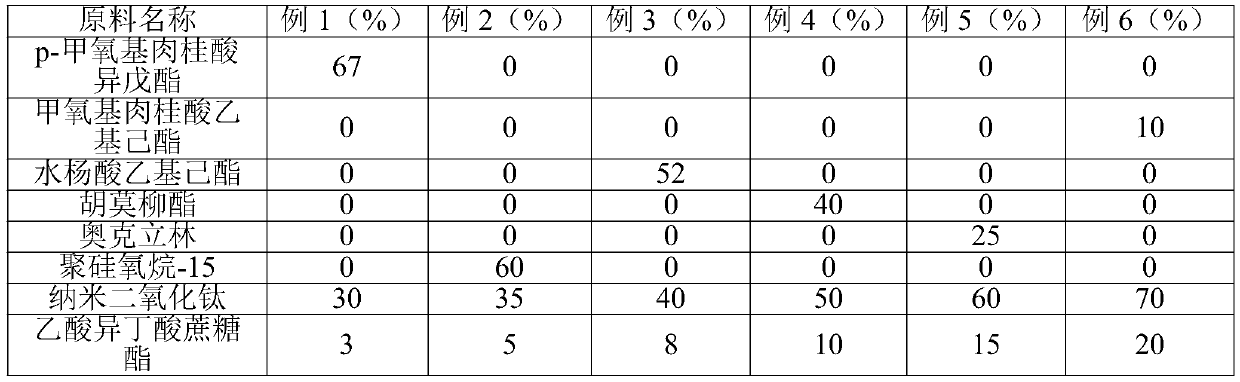

[0026] Examples 1-6 The specific formula of the sunscreen composition of the present invention is shown in Table 1, and the raw materials in the formula are calculated by mass percentage.

[0027] Table 1 Example 1-6 sunscreen composition formula

[0028]

Embodiment 1

[0029] The preparation method of embodiment 1 sunscreen composition of the present invention comprises the following steps:

[0030] (1) Put p-methoxycinnamate isoamyl ester and sucrose acetate isobutyrate into the reaction kettle respectively, heat up to 45-60°C, stir evenly, and obtain the first mixture;

[0031] (2) pumping the reaction kettle to a vacuum state with a pressure of -0.5 to -0.2Mpa, while pumping the vacuum while pumping nano-titanium dioxide from the bottom of the reaction kettle, and stirring until the solid inorganic sunscreen agent is completely wetted to obtain the second mixture;

[0032](3) Keep the temperature of the reactor at 45-60°C, turn on the high-pressure mode, stir the second mixture obtained in step (2) until uniform, and homogenize at a high speed for 15-20Min to obtain the third mixture;

[0033] (4) Filter the third mixture obtained in step (3) to remove impurities by using a 300-500 mesh sieve to obtain the sunscreen composition of the pre...

Embodiment 2

[0034] Embodiment 2 The preparation method of sunscreen composition of the present invention comprises the following steps:

[0035] (1) Put polysiloxane-15 and sucrose acetate isobutyrate into the reaction kettle respectively, raise the temperature to 45-60°C, stir evenly, and obtain the first mixture;

[0036] (2) pumping the reaction kettle to a vacuum state with a pressure of -0.5 to -0.2Mpa, while pumping the vacuum while pumping nano-titanium dioxide from the bottom of the reaction kettle, and stirring until the solid inorganic sunscreen agent is completely wetted to obtain the second mixture;

[0037] (3) Keep the temperature of the reactor at 45-60°C, turn on the high-pressure mode, stir the second mixture obtained in step (2) until uniform, and homogenize at a high speed for 15-20Min to obtain the third mixture;

[0038] (4) Filter the third mixture obtained in step (3) to remove impurities by using a 300-500 mesh sieve to obtain the sunscreen composition of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com