Joint surface stiffness test bench and using method thereof

A technology that combines surfaces and test benches, and is applied in the testing, measuring devices, instruments, etc. of machine/structural components to achieve the effect of wide application, easy replacement and maintenance, and realization of changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

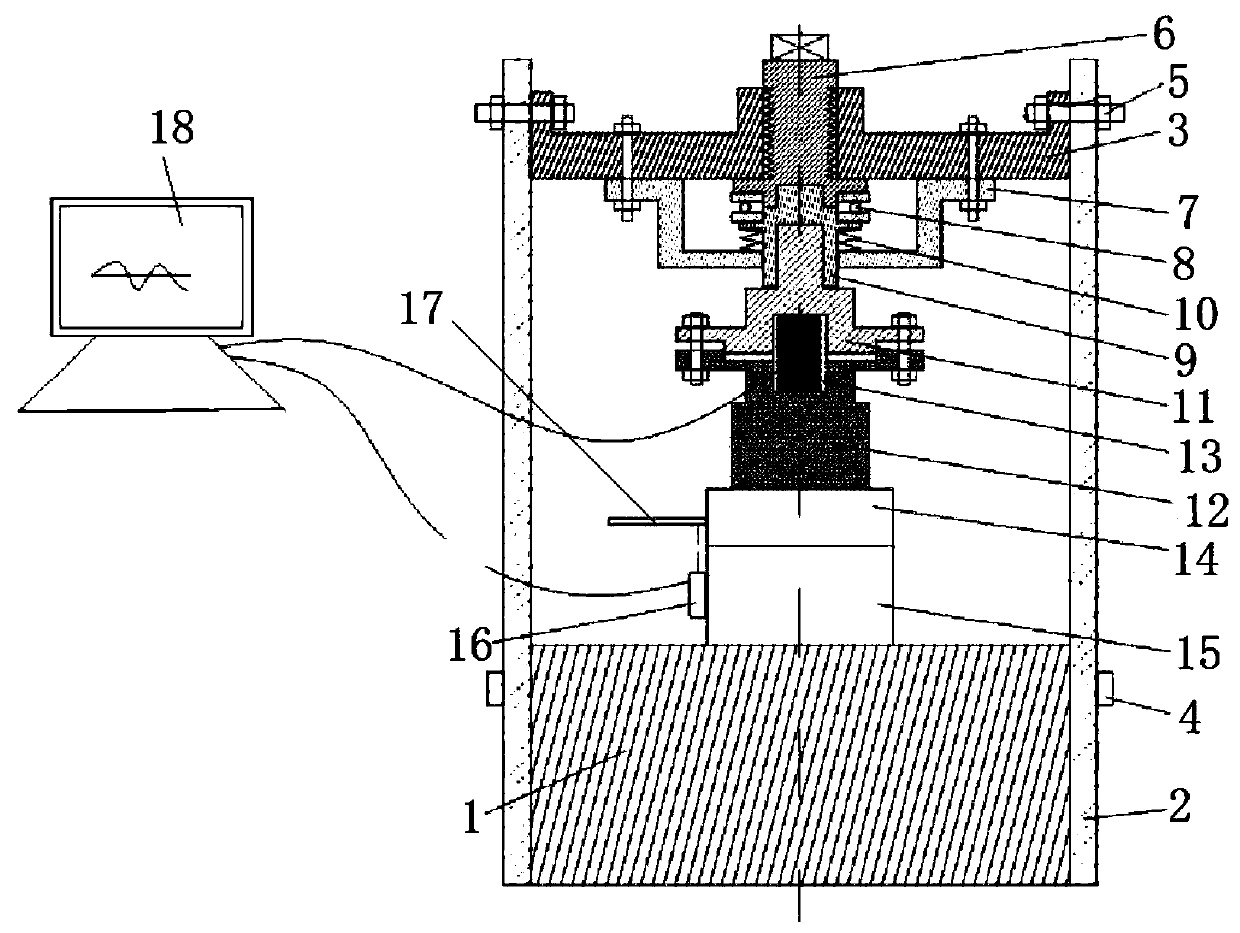

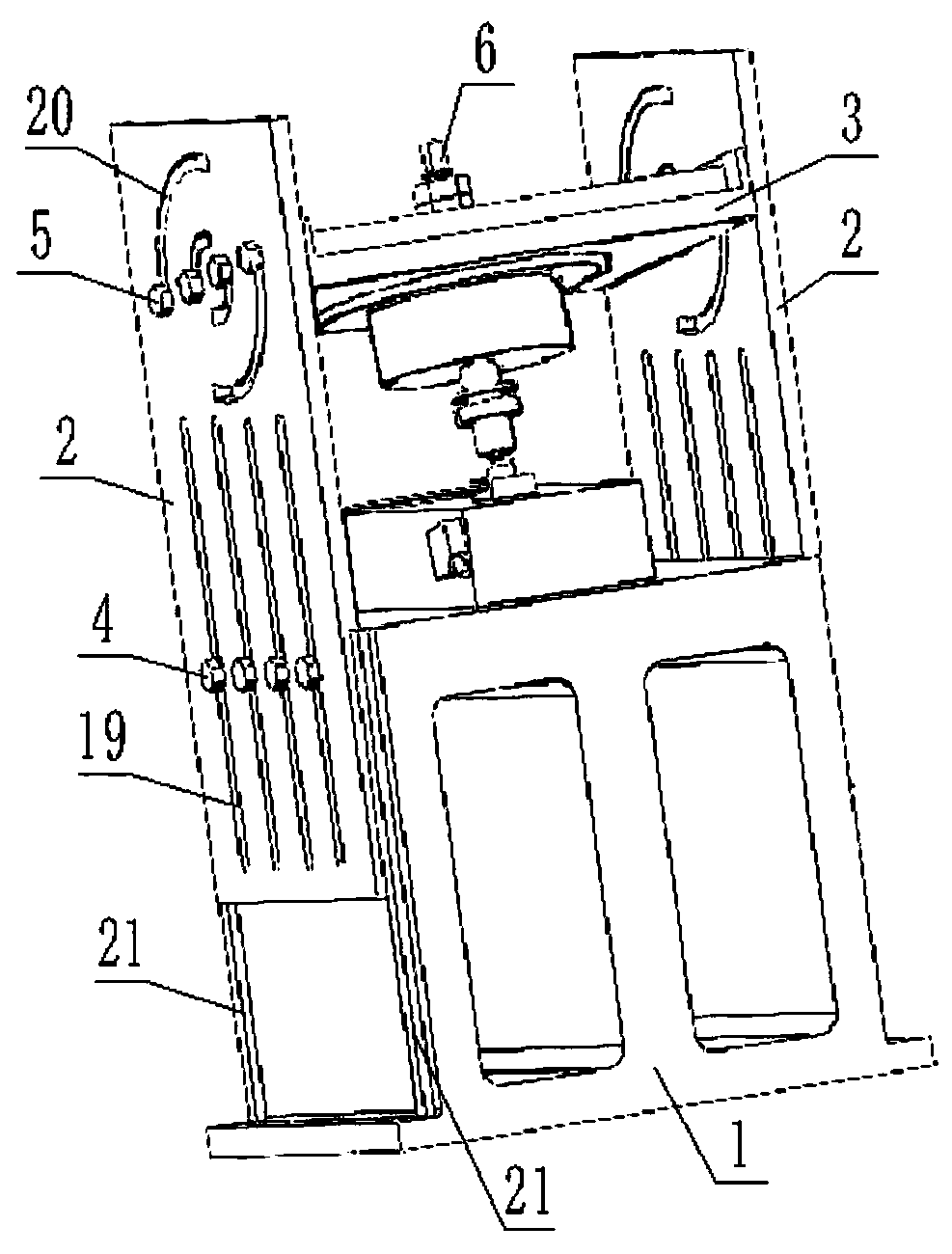

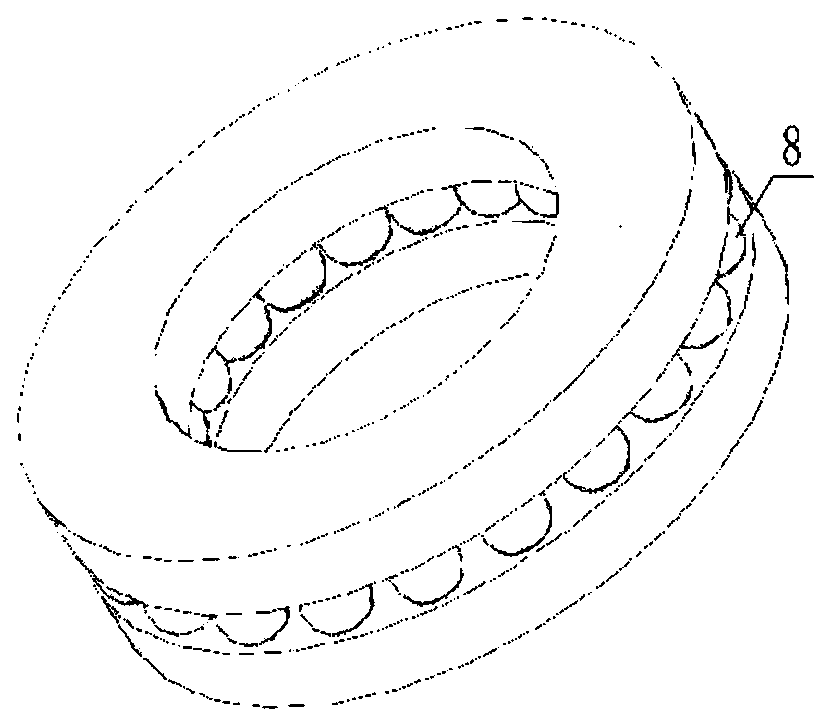

[0024] A joint surface stiffness test bench, such as figure 1 , 2 , 3, including the base 1, the part II15 placed on the base 1, the part I14 placed on the part II15, the laser displacement sensor 16 is installed on the part II15, the reflector 17 is installed on the part I14, and the laser displacement sensor 16 The emitted laser light acts on the reflection plate 17 . A side plate 2 is respectively connected to two opposite side walls of the base 1, and each side plate 2 is provided with at least one long hole 19 along its length direction, and the fastening bolts 4 correspondingly pass through each long hole. 19 and be connected with the positioning screw holes provided on the base 1. An upper cover 3 is connected between the two side plates 2 above the base 1, and a pressure detection mechanism is connected on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com