Probe type high-accuracy force sensor based on quartz resonator

A technology of quartz resonator and force sensor, which is applied in the direction of measurement, instrumentation, and force measurement by measuring the frequency change force of the stressed vibrating element, can solve the problems of complex processing technology and difficult processing, and achieve mature technology, High machining accuracy and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

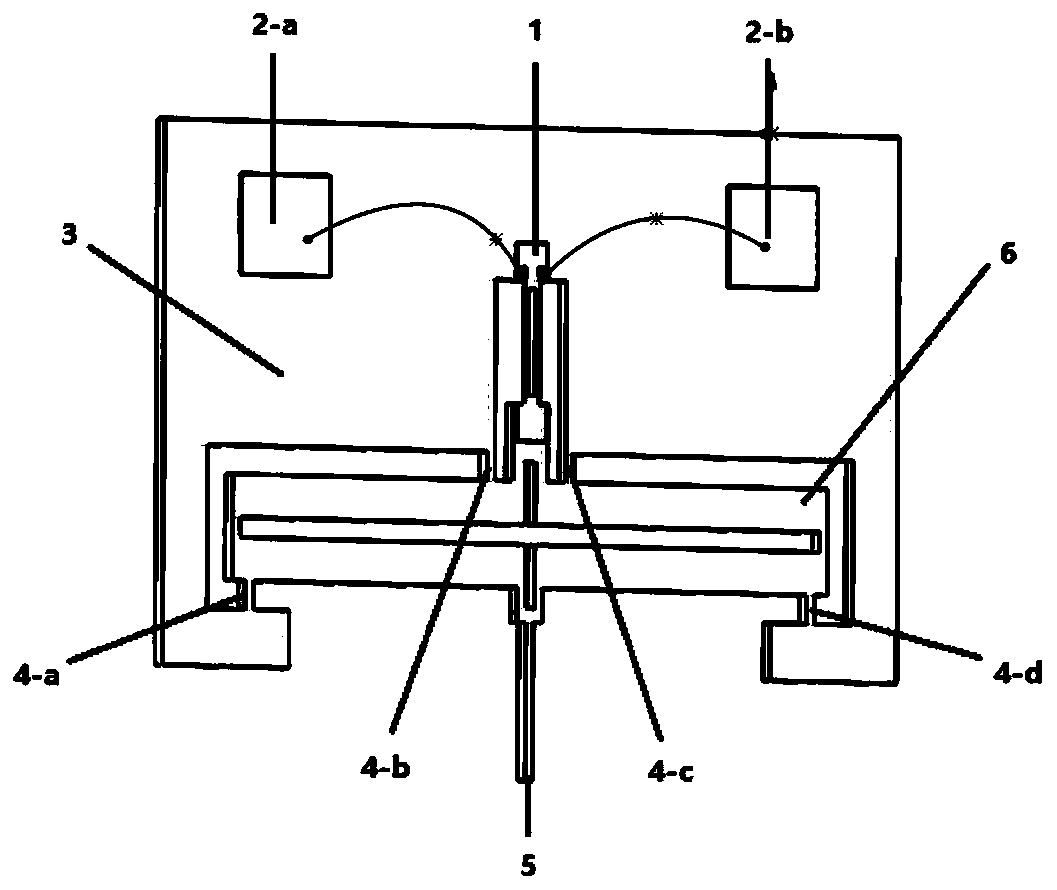

[0016] The structure and working principle of the present invention will be described in detail below with reference to the accompanying drawings.

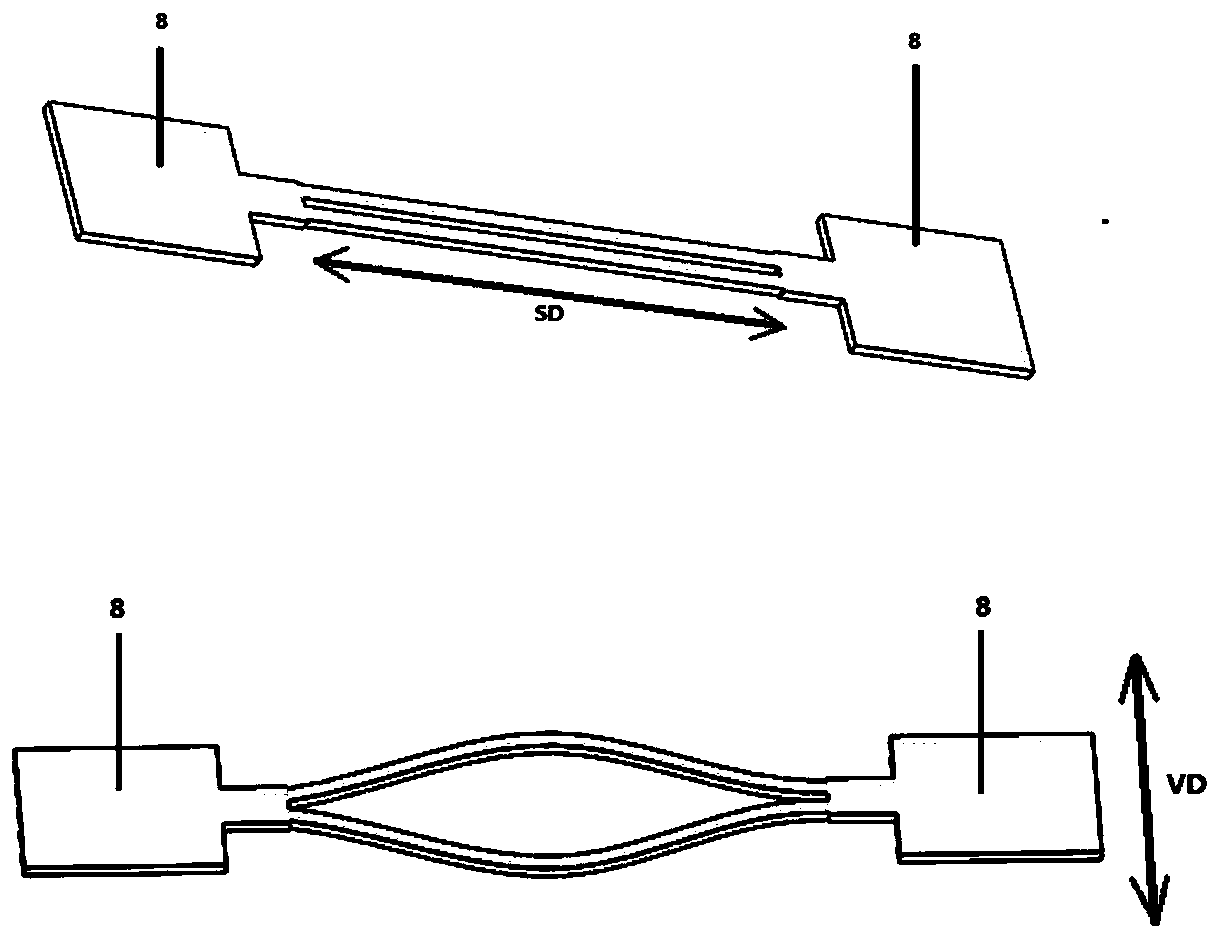

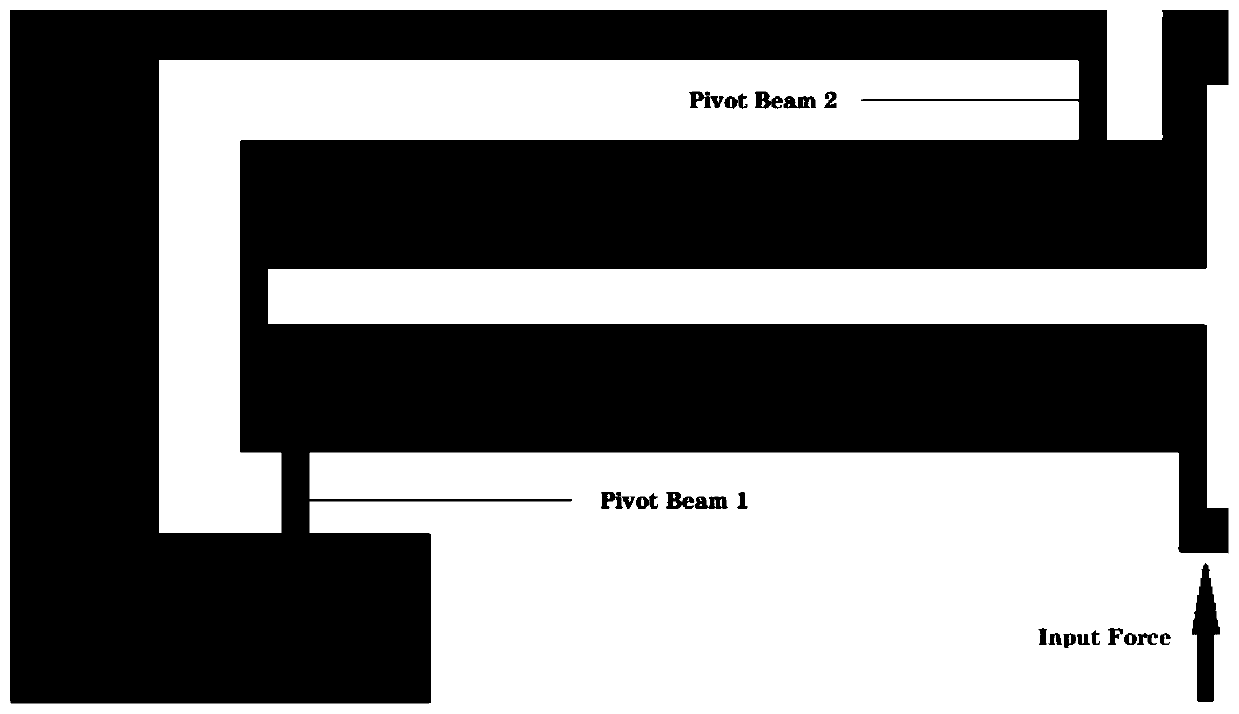

[0017] Reference figure 1 , A probe-type high-precision force sensor based on a quartz resonator, including a probe 5 as the input end of the sensor. The probe 5 is connected to the input end of the second-order amplifying beam 6, and the axial direction of the second-order amplifying beam 6 is the sensitive direction , The force is input in the axial direction; the second-order amplification beam 6 is connected to the silicon base frame 3 through four fulcrum beams 4-a, 4-b, 4-c, 4-d, and the force is amplified by the principle of leverage; The output end of the amplifier beam 6 and one end of the quartz tuning fork beam 1 are fixedly connected with organic glue. The quartz tuning fork beam 1 is located in the hollow rectangle of the silicon base frame 3, and the other end of the quartz tuning fork beam 1 is fixed on the silicon base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com