Meshing type pipe pile quick coupling structure

A kind of joint structure and fast technology, which can be used in infrastructure engineering, sheet pile walls, buildings, etc., and can solve problems such as inaccurate alignment of connecting pins and connecting grooves, rotten ends of pipe pile joints, and reduced bearing capacity of pipe piles. , to shorten the construction time, prevent damage, and increase the meshing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

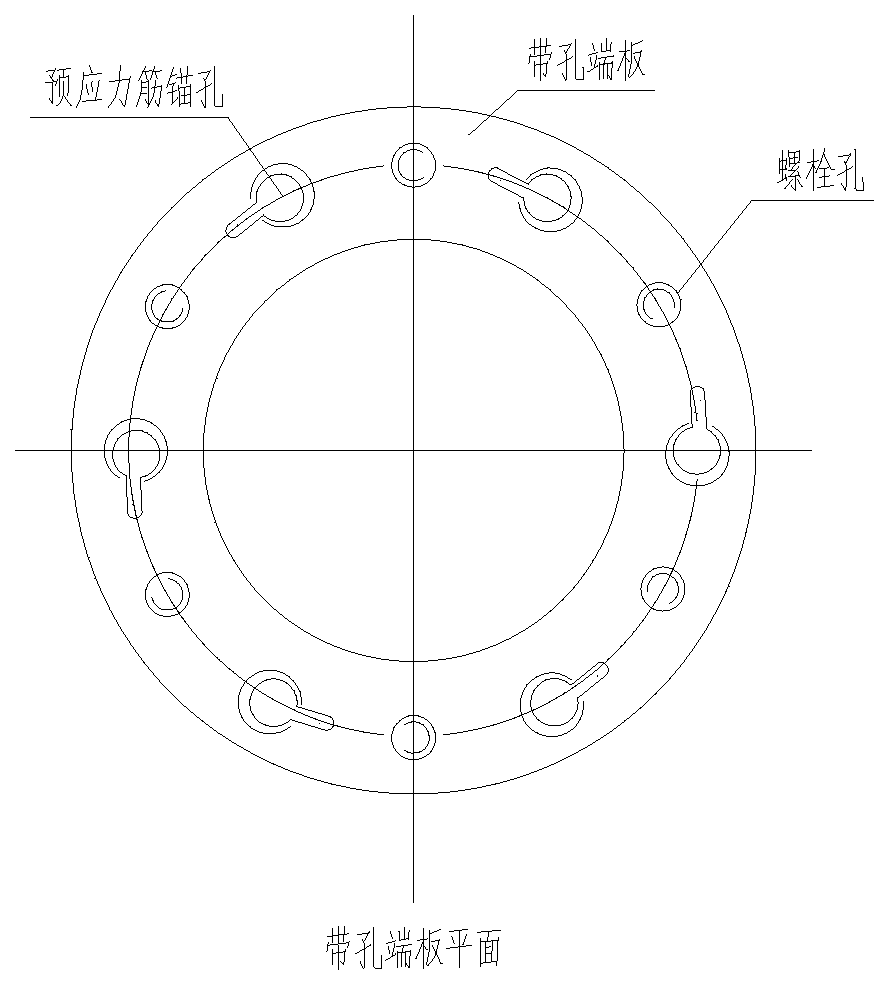

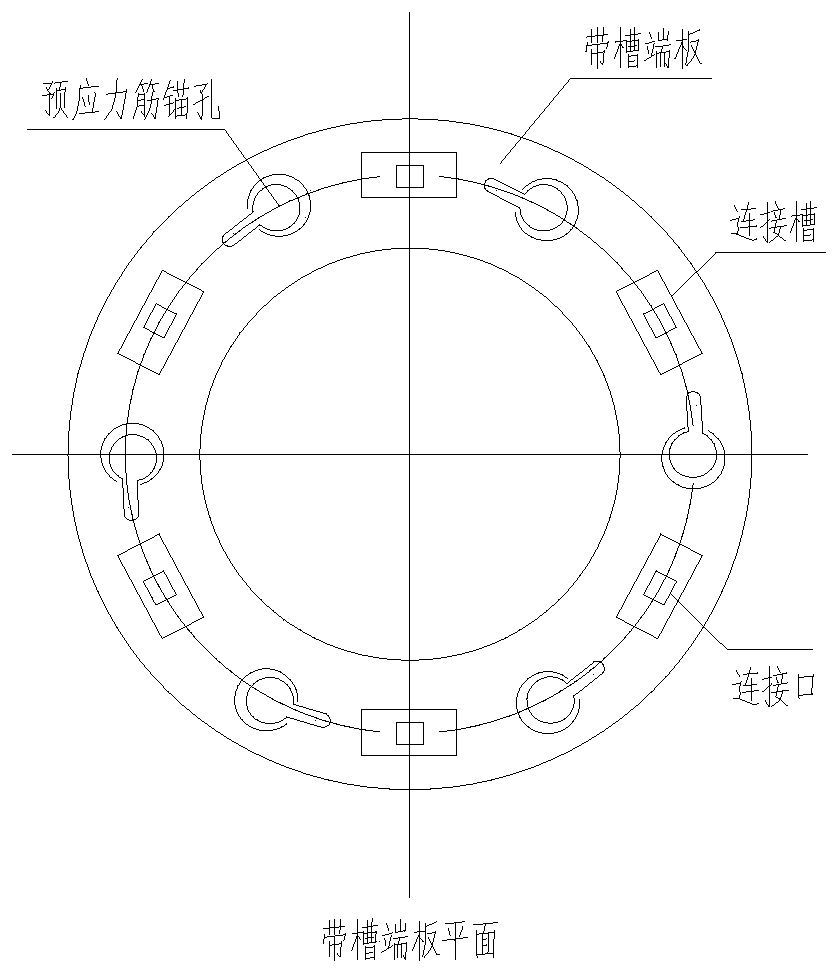

[0027]The main structure of the meshing pipe pile quick joint structure involved in this embodiment includes an upper section pipe pile 1, an upper end plate 2, a lower section pipe pile 3, a lower end plate 4, bolt holes 5, a connecting groove 6, a connecting port 7, a prestressed Rib anchor hole 8, connecting pin 9, lower meshing tooth 12, nut 13, connecting block 14, upper meshing tooth 15 and pressure spring 16; the bottom of the upper segment pipe pile 1 is provided with an upper end plate 2 of circular structure, and the lower The top of the joint pipe pile 3 is provided with a lower end plate 4 of circular structure, the upper end plate 2 is provided with four bolt holes 5 of circular structure at equal intervals, and the lower end plate 4 is provided with four rectangular structure bolt holes at equal intervals. The connection groove 6, the center of the connection groove 6 is provided with a cross-shaped connection port 7, the position of the bolt hole 5 corresponds to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com