Processing and spinning method for waste water-containing spandex stock solution

A technology of spandex and dope, which is applied in spinning solution preparation, sustainable manufacturing/processing, rayon recycling, etc. It can solve the problems that there are no reports about spinning back spinning of aqueous waste dope, and achieve good benefits and high mechanical properties and resilience, reducing shipping and handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

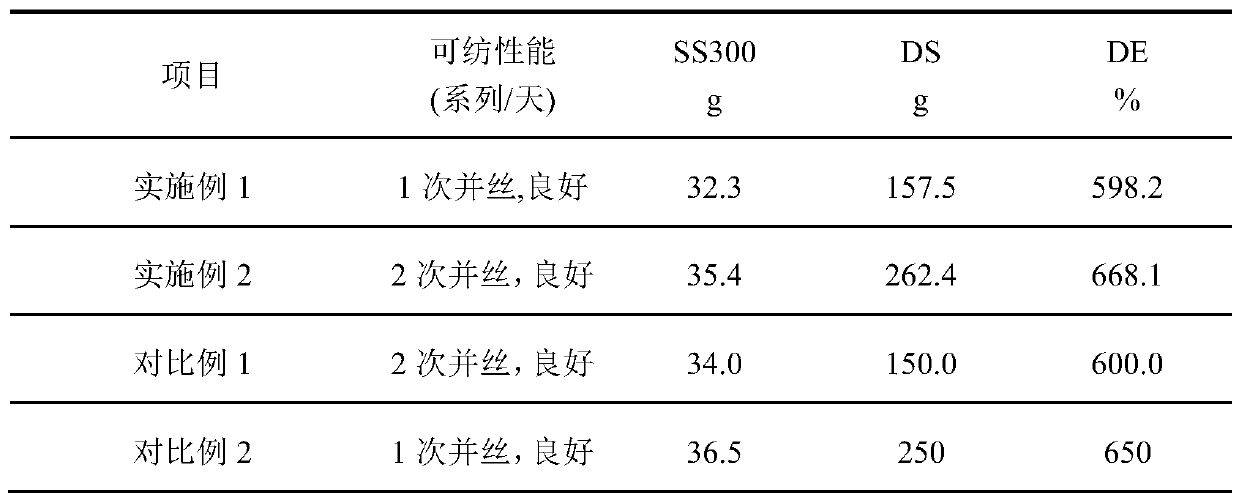

Examples

Embodiment 1

[0026] 1 Screening and granulating the waste stock solution to produce solid stock solution particles with a size of 2 to 5 mm;

[0027] 2 Fill the raw liquid particles into the dryer, take them out after drying for 5 hours, and put them into a sealed bag;

[0028] 3 In a melting tank equipped with a stirring device, add 450kg of DMCA solvent and 200kg of solid stock solution particles in sequence, stir and heat up to 50°C, add 0.3kg of viscosity stabilizer solution, add 1.2kg of antioxidant, and prepare a solution after mixing thoroughly And take a sample to detect the concentration; adjust the concentration by adding a solvent to dissolve, and measure the concentration of the stock solution at 31%, with a viscosity of 5500Poise, to prepare a uniform and stable polymerization stock solution;

[0029] 4. After the polymerization stock solution is filtered, it is transferred to the stock solution storage tank and stored for 26 hours to make it mature and stable;

[0030] 5. Co...

Embodiment 2

[0032] 1 Screening and granulating the waste stock solution to produce solid stock solution particles with a size of 10-15mm;

[0033] 2 Fill the raw liquid particles into the dryer, dry for 8 hours, and put them into a sealed bag;

[0034] 3 In a melting tank equipped with a stirring device, add 655kg of DMCA solvent and 303kg of solid stock solution particles in sequence, stir and heat up to 45°C, add 0.5kg of viscosity stabilizer solution, and add 1.3kg of antioxidant, and prepare the pre-mixed solution after mixing thoroughly. Dissolve the solution, and take a sample to detect the concentration; adjust the concentration by adding DMAC to dissolve, and measure the concentration of the stock solution at 31.5%, with a viscosity of 6700Poise, to prepare a uniform and stable polymerization stock solution;

[0035] 4. After the polymerization stock solution is filtered, it is transferred to the stock solution storage tank and stored for 30 hours to make it mature and stable;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com