Method and system for preparing granular fuel by mixing waste pit mud and vinasse of Maotai-flavor liquor

A technology of granular fuel and sauce-flavored wine, which is applied in the direction of waste fuel, fuel, solid fuel, etc., can solve the problems of pit mud being easy to form, difficult to form, and difficult to burn, and achieve high calorific value, high density, and elimination of odor pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

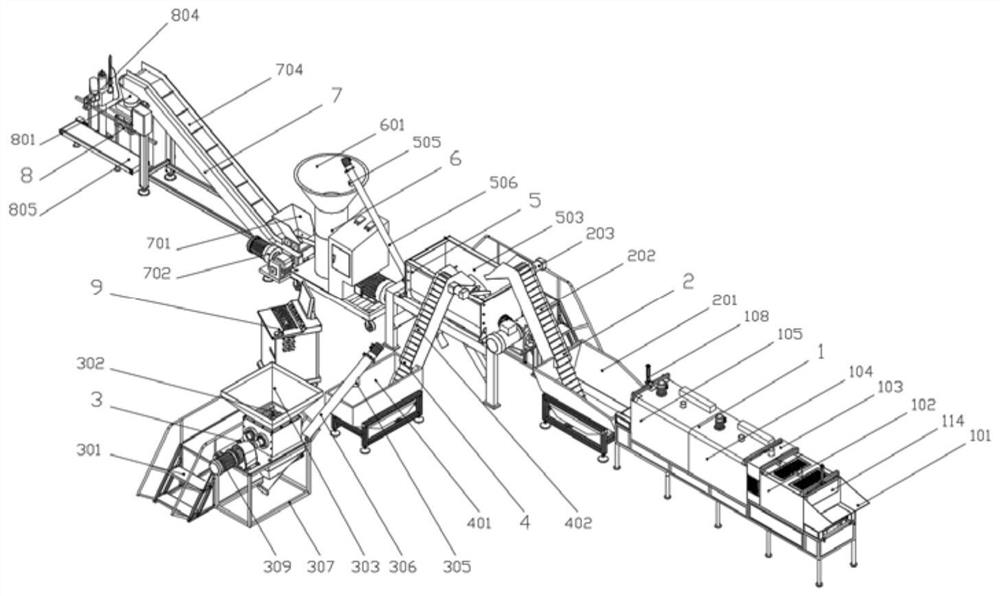

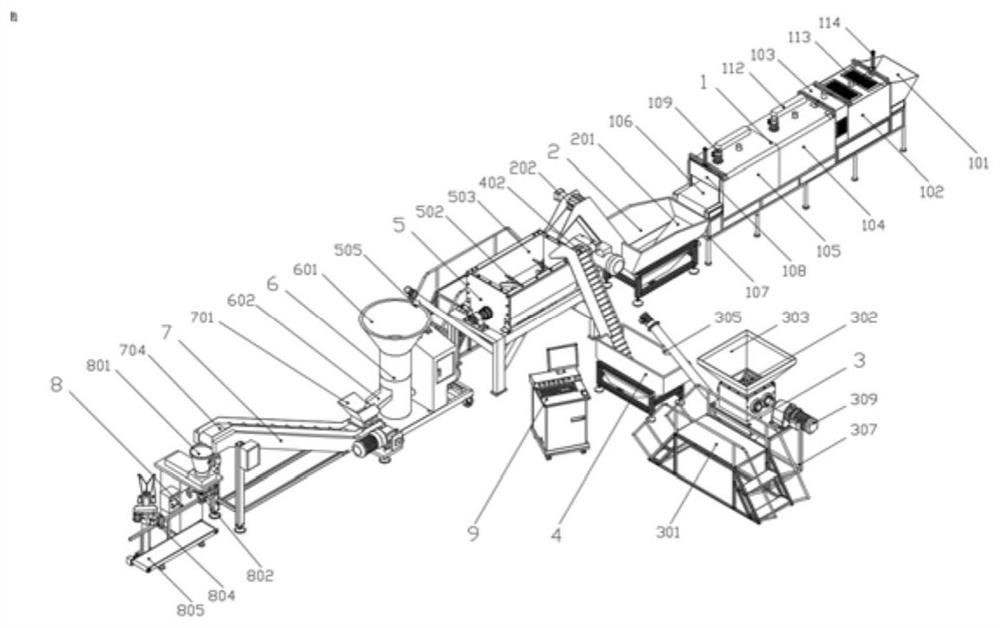

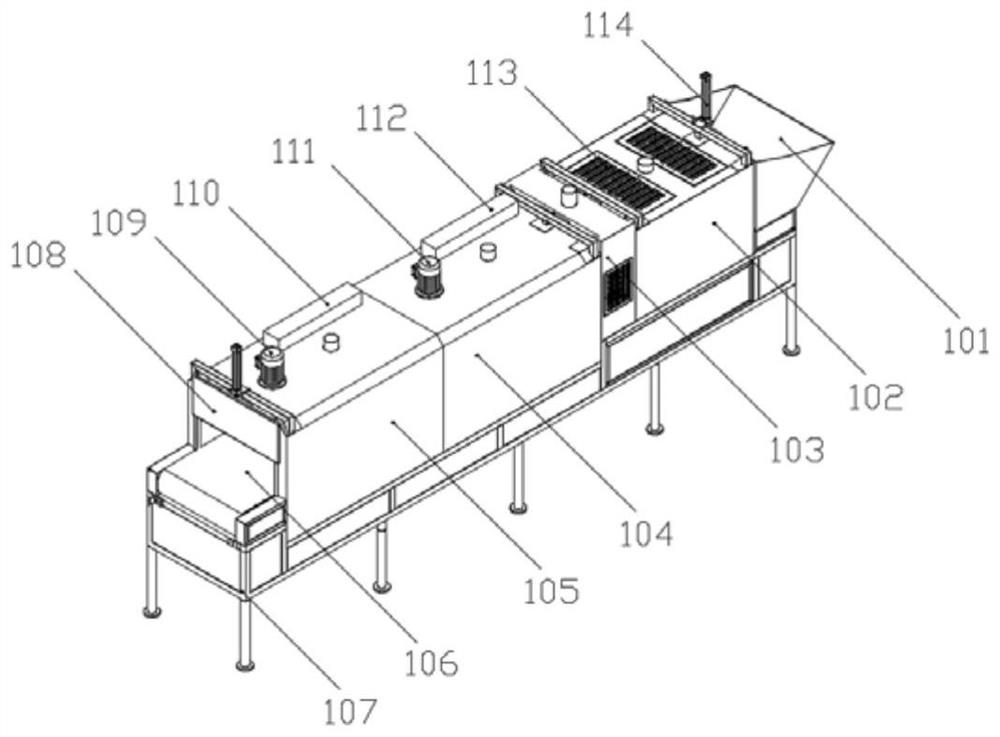

[0042] refer to Figure 1 to Figure 19 , the present embodiment provides a method for preparing pellet fuel by mixing the discarded pit mud and lees of Maotai flavored wine, the method is as follows:

[0043] 1) drying the discarded distiller's grains (moisture content of 80%-100%) of Maotai-flavored wine, so that the moisture content is 5%-10%;

[0044] 2) Pulverize the discarded pit mud of Maotai wine (blocky, with a moisture content of about 20%-30%);

[0045] 3) mixing the above-mentioned dried distiller's grains and crushed cellar mud, wherein the percentage by weight of distiller's grains and cellar mud is: distiller's grains 50%-60%, cellar mud 40%-50%;

[0046] 4) molding the above-mentioned mixed vinasse and pit mud press molding machine;

[0047] 5) The above-mentioned shaped pellet fuel is cooled and bagged.

[0048] This embodiment also provides a system for preparing pellet fuel by mixing the discarded pit mud and lees of Maotai-flavored wine, including a lees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com