Special organic-inorganic granular compound fertilizer for facility tomatoes

A technology of inorganic granules and compound fertilizers, applied in the direction of organic fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of microbial imbalance, unfavorable tomato early growth and development, soil compaction, etc., and achieve vitamin C content and sugar-acid ratio. Suitable for large-scale production, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

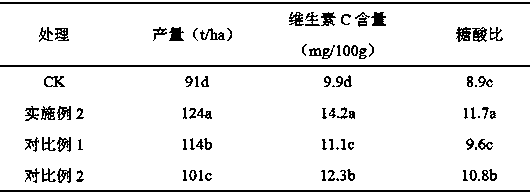

Examples

Embodiment 1

[0016] A preparation method of special organic-inorganic granular compound fertilizer for facility tomato, specifically comprising the following steps:

[0017] (1) Mixing and granulation of inorganic components: Grind 10 parts of solid urea, 10 parts of superphosphate and 20 parts of potassium sulfate into powder at 60°C, add distilled water with a mass fraction of 10%, compress and granulate into a 5mm diameter Inorganic fertilizer mixing ball;

[0018] (2) Packing and granulation of organic components: Mix 5 parts of crushed straw powder, 10 parts of decomposed rabbit manure, 10 parts of earthworm manure, and 10 parts of Hericium erinaceus mushroom residue, and adjust the water content to not less than 45% w / v. Wrap it on the periphery of the inorganic fertilizer mixed ball prepared in step (1), and then compress and granulate to form an organic-inorganic fertilizer fertilizer ball with a diameter of 1.5 cm; the mass ratio of the organic component to the inorganic component...

Embodiment 2

[0022] A preparation method of special organic-inorganic granular compound fertilizer for facility tomato, specifically comprising the following steps:

[0023] (1) Mixing and granulation of inorganic components: Grind 15 parts of solid urea, 15 parts of superphosphate and 25 parts of potassium sulfate into powder at 60°C, add distilled water with a mass fraction of 10%, compress and granulate into a 5mm diameter Inorganic fertilizer mixing ball;

[0024] (2) Organic ingredients wrapped and re-granulated: Mix 10 parts of crushed straw powder, 20 parts of decomposed rabbit manure, 10 parts of earthworm manure, and 20 parts of Hericium erinaceus mushroom residue, and adjust the water content to not less than 45% w / v. Wrap it on the periphery of the inorganic fertilizer mixed ball prepared in step (1), and then compress and granulate to form an organic-inorganic fertilizer fertilizer ball with a diameter of 1.5 cm; the mass ratio of the organic component to the inorganic componen...

Embodiment 3

[0028] A preparation method of special organic-inorganic granular compound fertilizer for facility tomato, specifically comprising the following steps:

[0029] (1) Mixing and granulation of inorganic components: Grind 20 parts of solid urea, 15 parts of superphosphate, and 25 parts of potassium sulfate into powder at 60°C, add distilled water with a mass fraction of 10%, compress and granulate into a 5mm diameter Inorganic fertilizer mixing ball;

[0030] (2) Organic ingredients wrapped and re-granulated: Mix 5 parts of crushed straw powder, 10 parts of decomposed rabbit manure, 5 parts of earthworm manure, and 30 parts of Hericium erinaceus mushroom residue, and adjust the water content to not less than 45% w / v Wrap it on the periphery of the inorganic fertilizer mixed ball prepared in step (1), and then compress and granulate to form an organic-inorganic fertilizer fertilizer ball with a diameter of 1.5cm; the mass ratio of the organic component to the inorganic component i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com