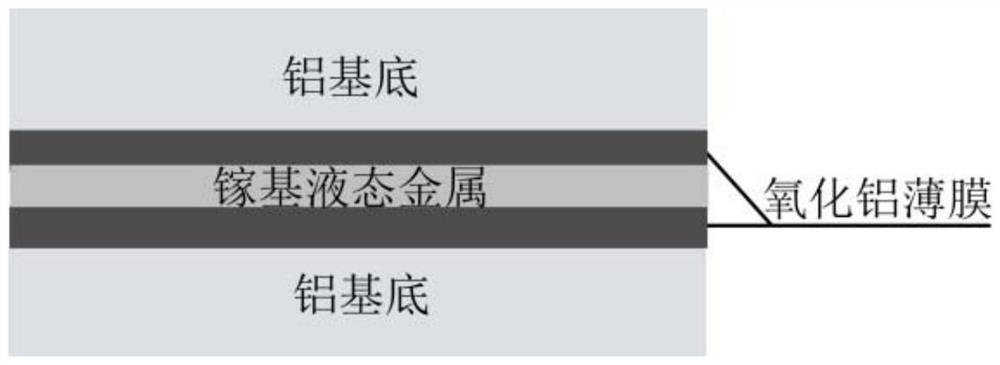

A method of applying gallium-based thermal interface materials to aluminum substrates to enhance interfacial heat transfer

A thermal interface material, aluminum substrate technology, applied in chemical instruments and methods, surface reaction electrolytic coatings, electrolytic coatings, etc., to achieve the effect of reducing contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for applying a gallium-based thermal interface material to an aluminum substrate to enhance interfacial heat transfer, comprising the steps of:

[0036] (1). Aluminum sheet pretreatment: Use a CNC milling machine to cut the pure aluminum sheet to the required size (a disc with a diameter of 11.4mm-13.8mm), immerse it in acetone solution with a mass fraction of 97vol%, and use ultrasonic The cleaning instrument was fully shaken for 10 minutes to remove the oil on the surface of the aluminum sheet. Then use absolute ethanol to clean according to the above steps, and finally use deionized water to clean according to the above steps to ensure that the surface of the aluminum sheet is clean and pollution-free.

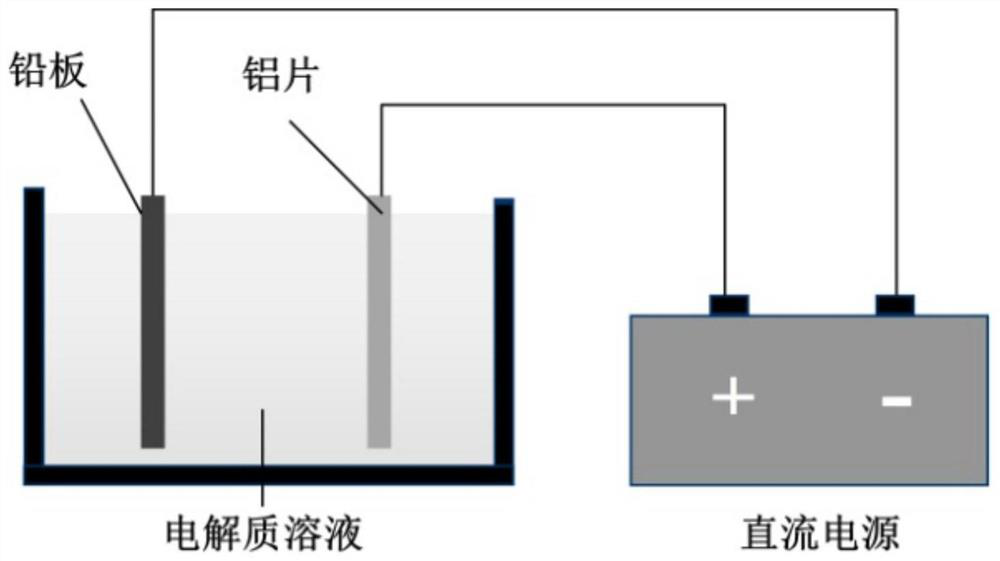

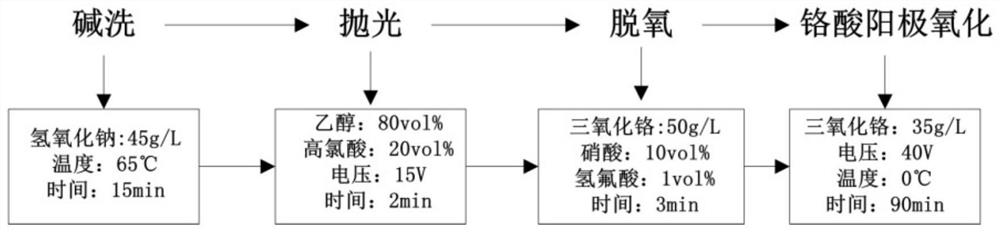

[0037] (2). Preparation of aluminum oxide film: use an anodic oxidation reaction device to oxidize the surface of the aluminum base, and the reaction device is as follows figure 1shown. The device is used for polishing and chromic acid anodizing treatment ...

Embodiment 2

[0050] A method for applying a gallium-based thermal interface material to an aluminum substrate to enhance interfacial heat transfer, comprising the steps of:

[0051] (1). Aluminum sheet pretreatment: Use a CNC milling machine to cut the pure aluminum sheet to the required size (a disc with a diameter of 11.4mm-13.8mm), immerse it in an acetone solution with a mass fraction of 85vol%, and use ultrasonic The cleaning instrument was fully shaken for 15 minutes to remove the oil on the surface of the aluminum sheet. Then use absolute ethanol to clean according to the above steps, and finally use deionized water to clean according to the above steps to ensure that the surface of the aluminum sheet is clean and pollution-free.

[0052] (2). Preparation of aluminum oxide film: use an anodic oxidation reaction device to oxidize the surface of the aluminum base, and the reaction device is as follows figure 1 shown. The device is used for polishing and chromic acid anodizing treatm...

Embodiment 3

[0060] A method for applying a gallium-based thermal interface material to an aluminum substrate to enhance interfacial heat transfer, comprising the steps of:

[0061] (1). Aluminum sheet pretreatment: Use a CNC milling machine to cut the pure aluminum sheet to the required size (a disc with a diameter of 11.4mm-13.8mm), immerse it in acetone solution with a mass fraction of 90vol%, and use ultrasonic The cleaning instrument was fully shaken for 10 minutes to remove the oil on the surface of the aluminum sheet. Then use absolute ethanol to clean according to the above steps, and finally use deionized water to clean according to the above steps to ensure that the surface of the aluminum sheet is clean and pollution-free.

[0062] (2). Preparation of aluminum oxide film: use an anodic oxidation reaction device to oxidize the surface of the aluminum base, and the reaction device is as follows figure 1 shown. The device is used for polishing and chromic acid anodizing treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com