Method for preparing nickel porous materials based on nickel oxalate and sodium chloride co-mixing reducing method

A technology of porous materials and sodium chloride is applied in the field of preparation of nickel porous materials, which can solve the problems of large difference between metal powder and pore-forming agent, and it is difficult to achieve sufficient and uniform mixing. The effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the mass ratio, nickel oxalate powder (purity is 99%, particle size range is 80-120 mesh): sodium chloride powder (purity is 99%, particle size range is 80-120 mesh) = 7:1. Add the prepared nickel oxalate powder and sodium chloride powder into the planetary ball mill, use anhydrous alcohol as the ball mill dispersion medium, the ball-to-battery ratio is 4:1, the rotating speed is 100 rpm, and the ball milling time is 10 hours to obtain a uniform mixture . Dry the obtained mixture at a drying temperature of 50° C. and a time of 3 hours to obtain a fully dried mixture. In a hydrogen atmosphere, the obtained dry mixture is uniformly heated to 400° C. at a heating rate of 6° C. / min and kept for 60 minutes for reduction, and then cooled to obtain a mixed powder of nickel powder and sodium chloride powder. The obtained mixed powder is subjected to bidirectional compression at a unit pressure of 100 MPa, and the pressure is maintained for 1 second to obtain a comp...

Embodiment 2

[0034] According to the mass ratio, nickel oxalate powder (purity is 99%, particle size range is 120-200 mesh): sodium chloride powder (purity is 99%, particle size range is 120-200 mesh)=5.5:1. Add the prepared nickel oxalate powder and sodium chloride powder to the planetary ball mill, use anhydrous alcohol as the ball mill dispersion medium, the ball-to-battery ratio is 6:1, the rotating speed is 120 rpm, and the ball milling time is 12 hours to obtain a uniform mixture . Dry the obtained mixture at a drying temperature of 60°C and a time of 4 hours to obtain a fully dried mixture. In a hydrogen atmosphere, the obtained dry mixture is uniformly heated to 430°C at a temperature increase rate of 5°C / min and kept for 45 minutes for reduction, and then cooled to obtain a mixed powder of nickel powder and sodium chloride powder. The obtained mixed powder is subjected to bidirectional compression at a unit pressure of 150 MPa, and the pressure is maintained for 2 seconds to obtai...

Embodiment 3

[0037] According to the mass ratio, nickel oxalate powder (purity is 99%, particle size range is 200-300 mesh): sodium chloride powder (purity is 99%, particle size range is 200-300 mesh)=4:1, mix. Add the prepared nickel oxalate powder and sodium chloride powder into the planetary ball mill, use anhydrous alcohol as the ball mill dispersion medium, the ball-to-battery ratio is 9:1, the rotating speed is 150 rpm, and the ball milling time is 16 hours to obtain a uniform mixture . Dry the obtained mixture at a drying temperature of 70°C and a time of 4 hours to obtain a fully dried mixture. In a hydrogen atmosphere, the obtained dry mixture is uniformly heated to 450°C at a heating rate of 4°C / min and kept for 30 minutes for reduction, and then cooled to obtain a mixed powder of nickel powder and sodium chloride powder. The obtained mixed powder is subjected to bidirectional compression at a unit pressure of 200 MPa, and the pressure is maintained for 3 seconds to obtain a comp...

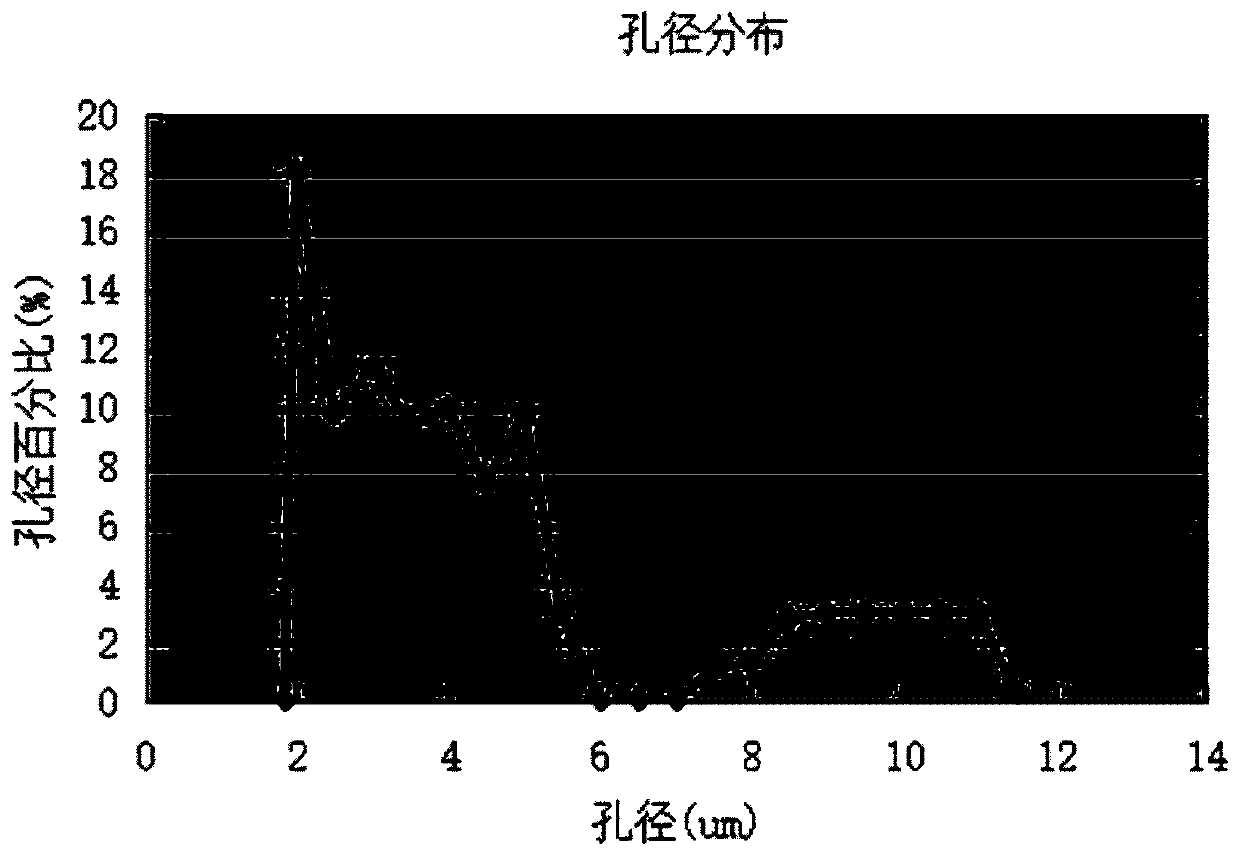

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com