Double-row self-propelled flax extraction machine and hydraulic transmission system thereof

A hydraulic transmission, self-propelled technology, applied in the direction of fluid pressure actuated system components, harvesters, mechanical equipment, etc., can solve the problems of high failure rate, long maintenance cycle, low productivity, etc., to achieve low failure rate, easy to use Easy maintenance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

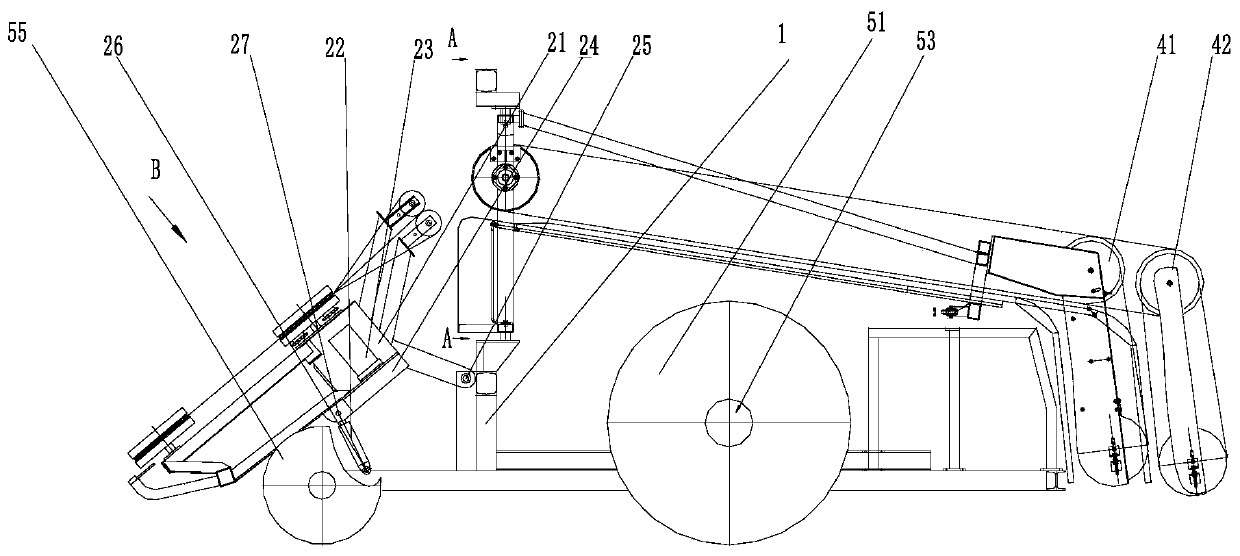

[0054] like figure 1 Shown is a schematic structural view of a double-row self-propelled hemp pulling machine provided by the present invention, including a self-propelled frame 1, characterized in that the hemp pulling mechanism, the hemp feeding mechanism and the hemp dropping mechanism are in the order from front to back Installed on the self-propelled frame 1, wherein the structure of each mechanism is as follows:

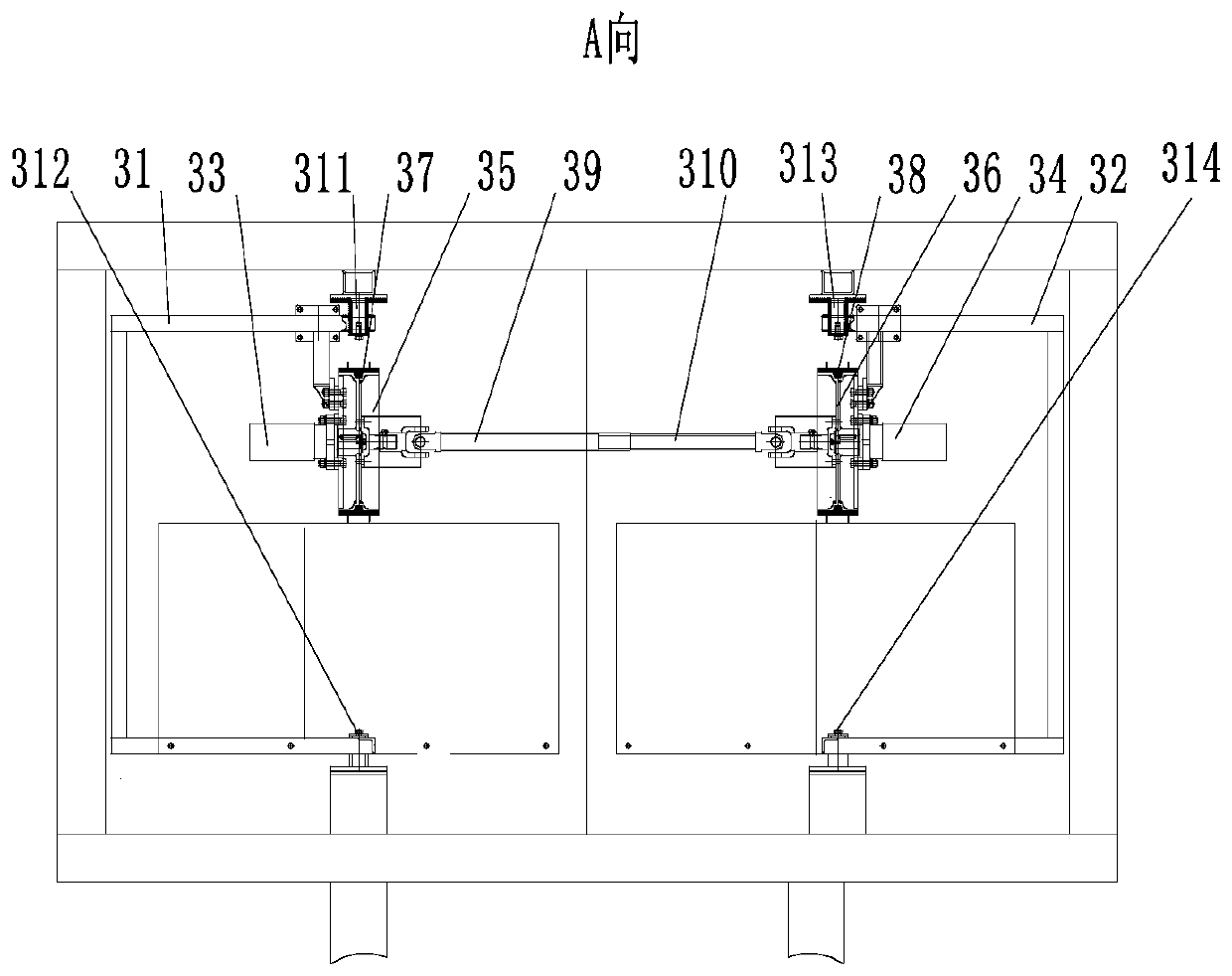

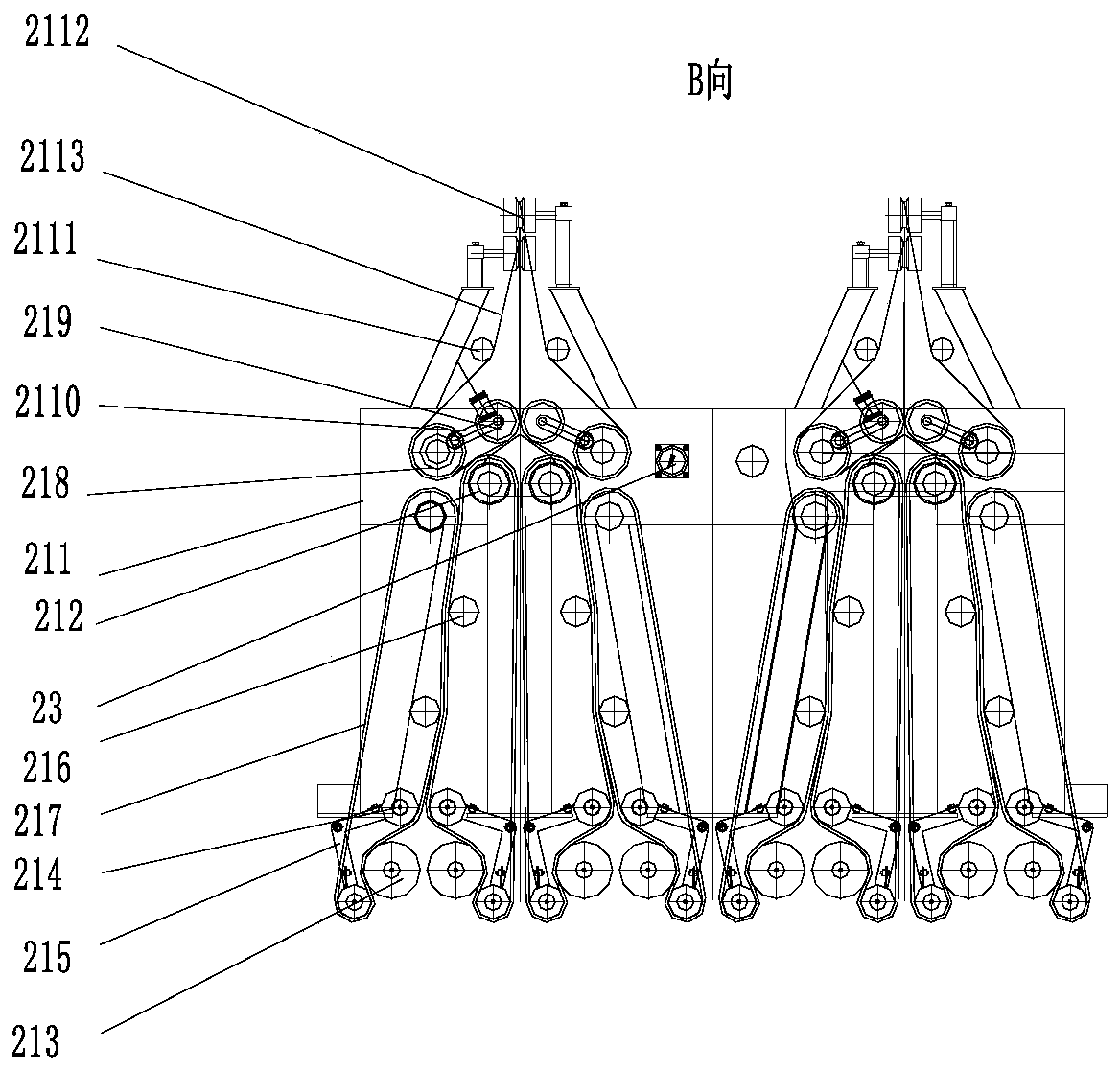

[0055] The hemp pulling mechanism includes a double row hemp pulling table 21, an oil cylinder 22 and a hemp pulling motor 23. The back side of the hemp table 21 is connected on the self-propelled frame 1; the oil cylinder 22 is connected between the self-propelled frame 1 and the double row hemp extraction table 21. The double row hemp pulling table 21 includes a left hemp pulling mechanism, a right hemp pulling mechanism and a hemp pulling frame 211, and the left hemp pulling mechanism and the right hemp pulling mechanism are symmetrically arranged on the he...

Embodiment 2

[0063] The present invention also provides a hydraulic transmission system for a double row self-propelled hemp pulling machine, such as Figure 5 As shown, it includes hydraulic oil tank 6, diesel engine 7, left travel motor 53, right travel motor 54, first high pressure relief valve 81, second high pressure relief valve 82, first hot oil shuttle valve 91, first low pressure relief valve Valve 101, walking two-way variable variable pump 11, hemp pulling motor 23, left hemp infusion motor 33, right hemp infusion motor 34, third high pressure relief valve 83, fourth high pressure relief valve 84, second hot oil shuttle valve 92, The second low-pressure relief valve 102, the two-way variable pump 12 for pulling out hemp and infusing hemp. Among them: the left travel motor 43, the right travel motor 44, the oil drain port of the hemp pulling motor 23, the oil filling hole and the oil drain port of the walking bidirectional variable pump 11 and the hemp pulling and transfusion bid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com