System device for ensuring continuous, stable and uniform feeding of fluorine carrying aluminum oxide

A technology of fluorine-loaded alumina and feeding system, which is applied in the field of continuous, stable and uniform feed system devices for fluorine-loaded alumina, which can solve the problems of high labor intensity for cleaning up impurities, inability of operators, and impact on compliance, and achieve stable production The effect of process quality, optimized monitoring means, and convenient centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

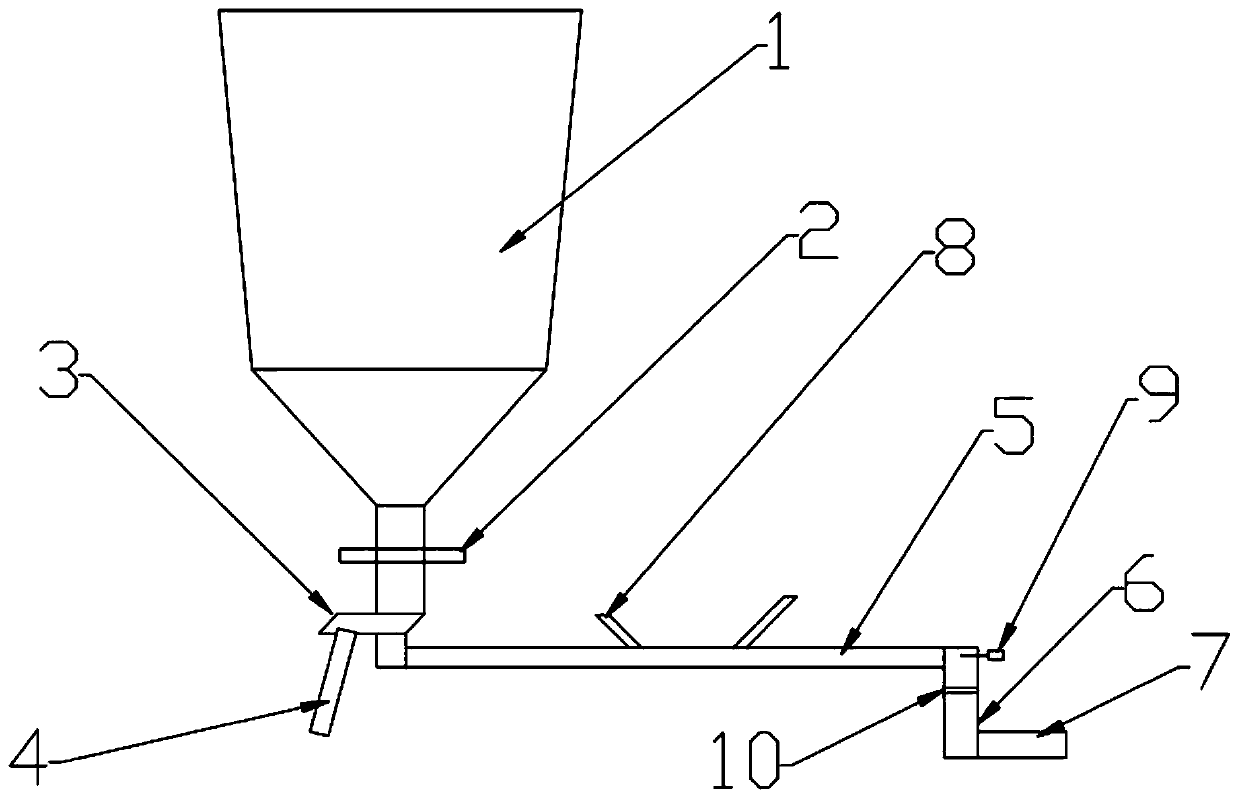

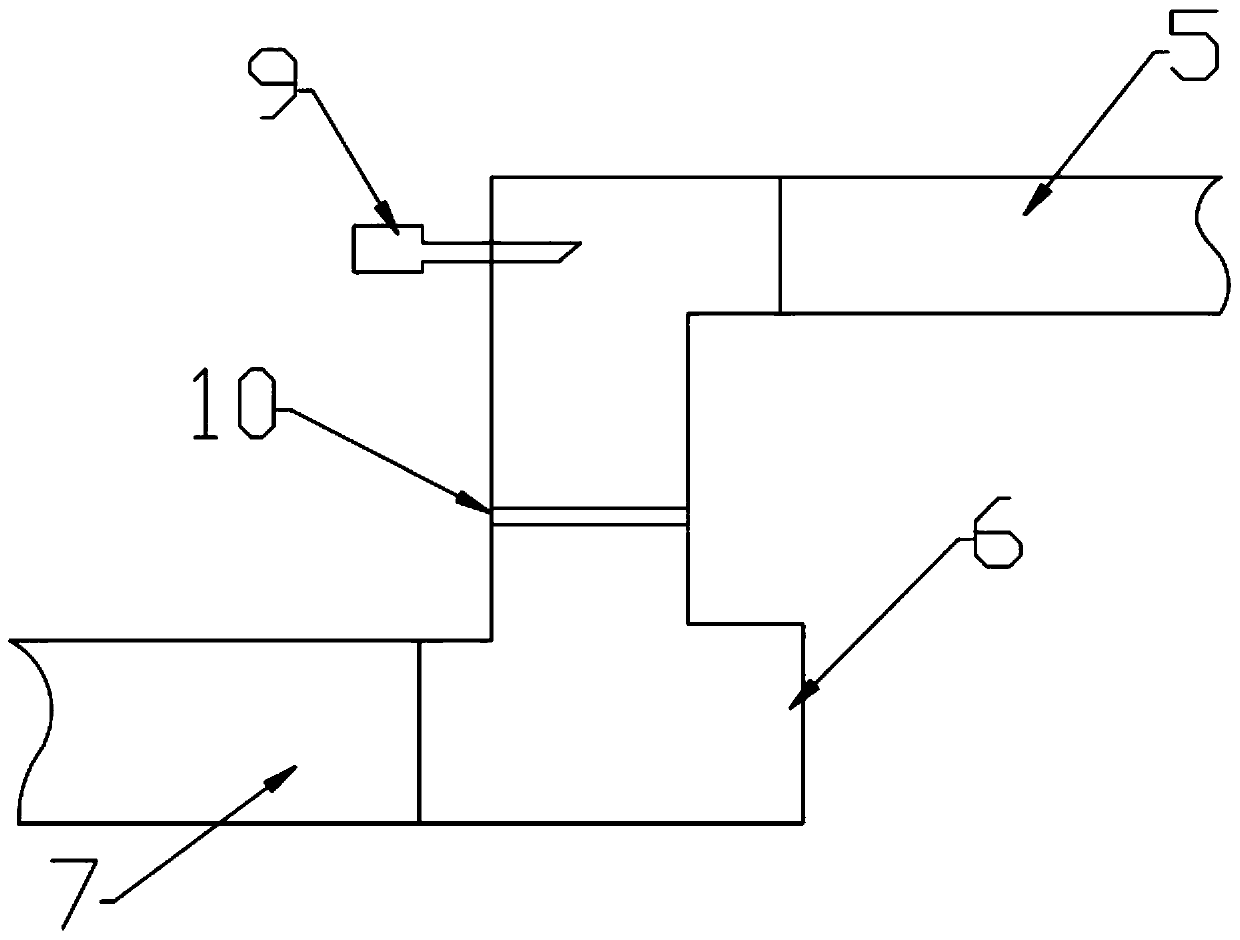

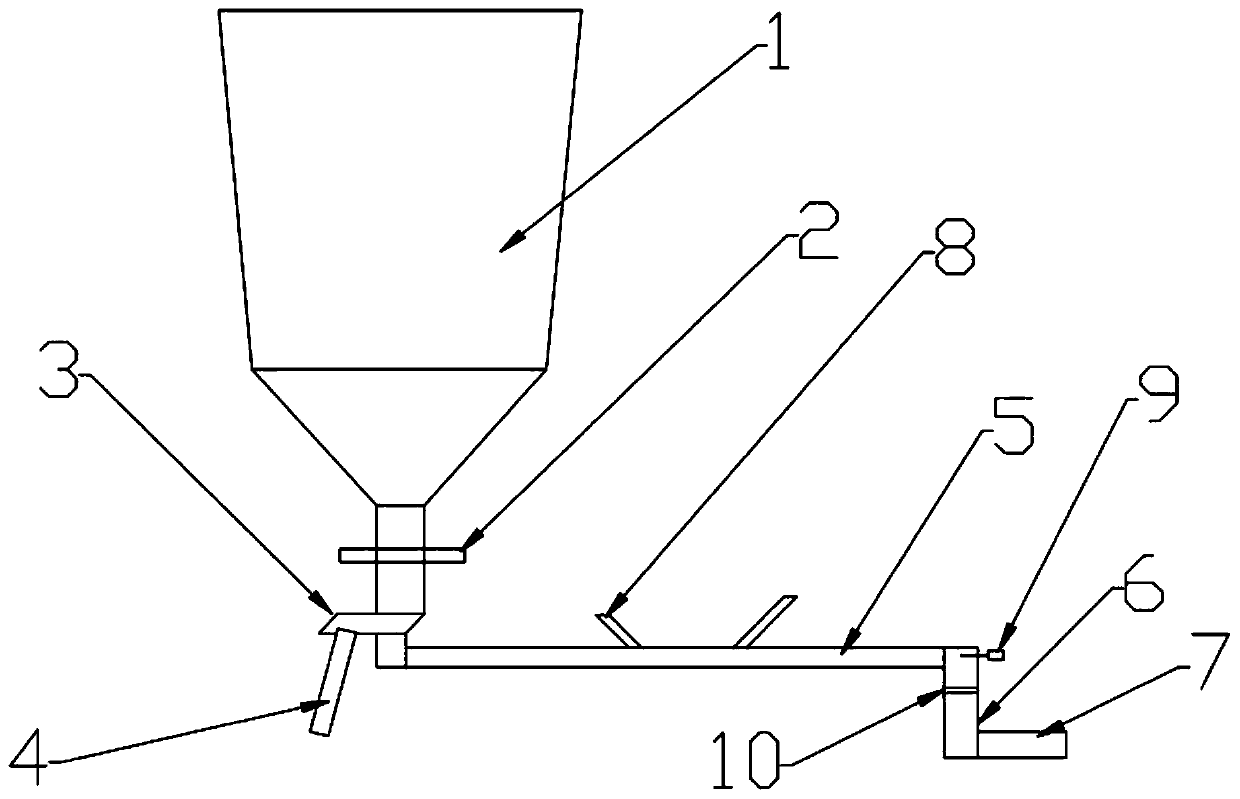

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Combined with the accompanying drawings, a system device for ensuring continuous, stable and uniform feeding of fluorine-containing alumina, including fresh alumina bin 1, impeller feeder 2, vibrating screen 3, impurity channel 4, horizontal chute 5, chute connector 6 and purification The main body 7, the impeller feeder 2 is installed under the fresh alumina bin 1, the vibrating screen 3 is located under the impeller feeder 2, the impurity channel 4 and the horizontal chute 5 are installed on Below the vibrating screen 3, the horizontal chute 5 is provided with a negative pressure pipe 8, and the chute connecting piece 6 is located at the end of the horizontal chute 5 away from the vibrating screen 3, and the chute connecting piece 6. Connect the purification body 7 with the horizontal chute 5, and the chute connector 6 is provided with a material lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com