Preparation method of nano motor of complex structure

A complex and nanotechnology, applied in the field of preparation of nanomotors with complex configurations, can solve problems such as poor carrying capacity, inability to carry large quantities of drugs, and difficulty in preparing hollow nanomotors, achieving high accuracy, suppressing Brownian motion, and processing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a complex configuration nanomotor: comprising the following steps:

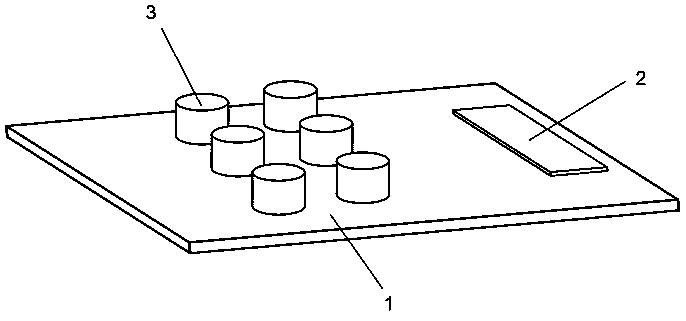

[0028] (1) Preparation of sound control platform: such as figure 1 As shown, the acoustic control platform is composed of a driving board 1, a piezoelectric transducer 2, and a microscale array structure 3; wherein, the driving board 1 is made of a highly transparent glass substrate with a length of 25 mm, a width of 15 mm, and a thickness of 1 mm. A micro-scale array structure 3 is fixed on one side; the piezoelectric transducer 2 is made of a piezoelectric ceramic sheet made of lead zirconate titanate. The same end of the scale array structure 3 is used to convert electrical energy into mechanical energy; the array structure 1 is a circular table configuration with a diameter of 10 μm and a height of 2 μm. It uses photosensitive adhesive AZ5214 as the substrate and is processed by photolithographic micromachining. Then use magnetron sputtering to form a silicon dioxide protect...

Embodiment 2

[0034] A method for preparing a complex configuration nanomotor: comprising the following steps:

[0035] (1) Preparation of sound control platform: such as figure 1As shown, the acoustic control platform is composed of a driving board 1, a piezoelectric transducer 2, and a microscale array structure 3; wherein, the driving board 1 is made of a highly transparent glass substrate with a length of 25 mm, a width of 15 mm, and a thickness of 1 mm. A micro-scale array structure 3 is fixed on one side; the piezoelectric transducer 2 is made of a piezoelectric ceramic sheet made of lead zirconate titanate. The same end of the scale array structure 3 is used to convert electrical energy into mechanical energy; the array structure 1 is a linear convex-table configuration with a line width of 10 μm and a height of 2 μm. It uses photosensitive adhesive AZ5214 as the substrate and is processed by photolithography micromachining. Formed, and then use magnetron sputtering to form a 100nm ...

Embodiment 3

[0041] A method for preparing a complex configuration nanomotor: comprising the following steps:

[0042] (1) Preparation of sound control platform: such as figure 1 As shown, the acoustic control platform is composed of a driving board 1, a piezoelectric transducer 2, and a microscale array structure 3; wherein, the driving board 1 adopts a highly transparent silicon substrate with a length of 25 mm, a width of 15 mm, and a thickness of 1 mm. A micro-scale array structure 3 is fixed on one side; the piezoelectric transducer 2 is made of a piezoelectric ceramic sheet made of lead zirconate titanate. The same end of the scale array structure 3 is used to convert electrical energy into mechanical energy; the array structure 1 is a square boss configuration with a side length of 20 μm and a height of 5 μm. It uses photosensitive adhesive S1813 as the substrate and is processed by photolithographic micromachining. , and then use magnetron sputtering to form a 150nm thick silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com