Non-bottom-beam frame for commercial vehicle liquefied gas bottles

A liquefied gas cylinder, no bottom beam technology, applied in the field of commercial vehicles, can solve the problems of easy deformation of frame welding, large overall weight, difficult installation and disassembly, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

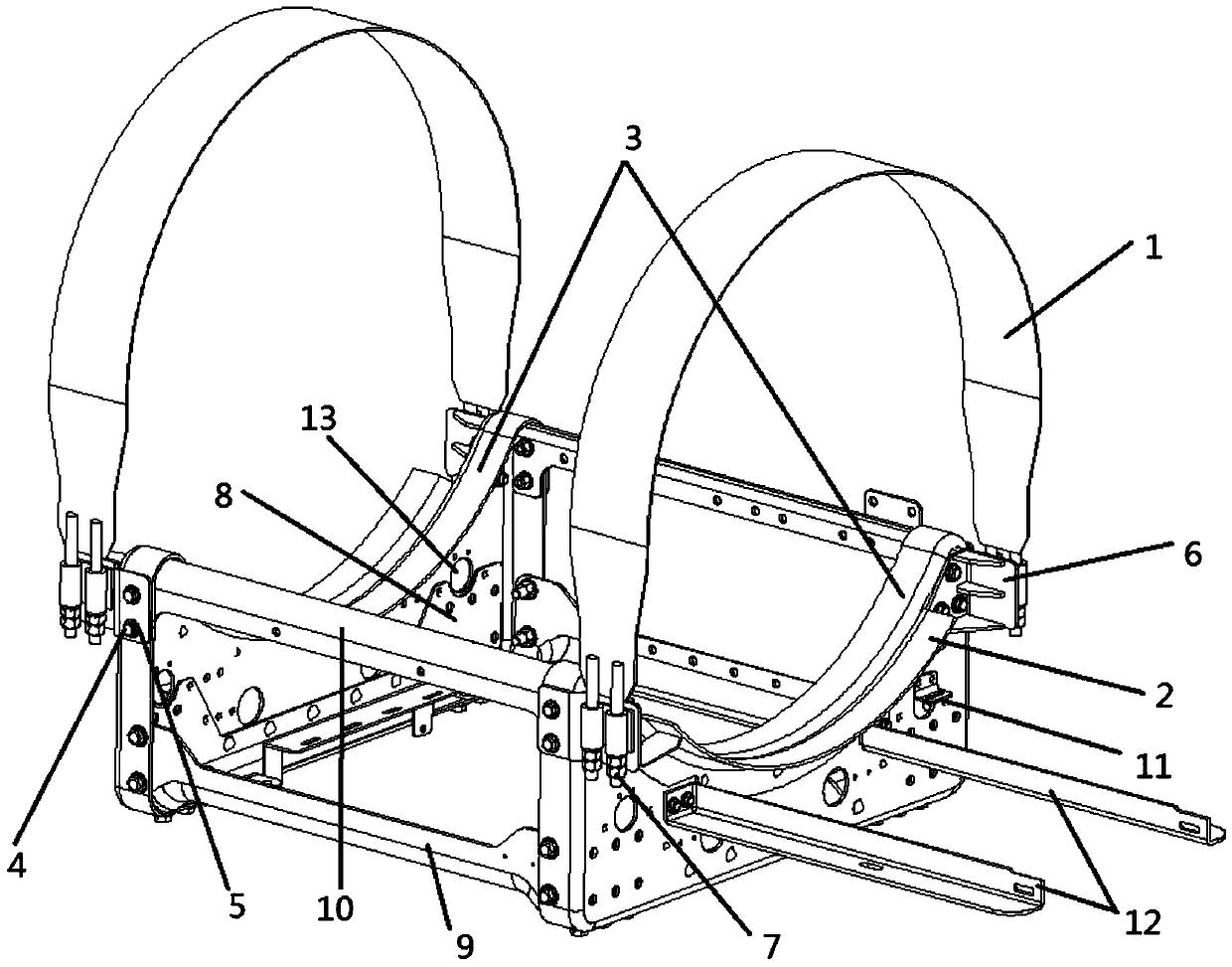

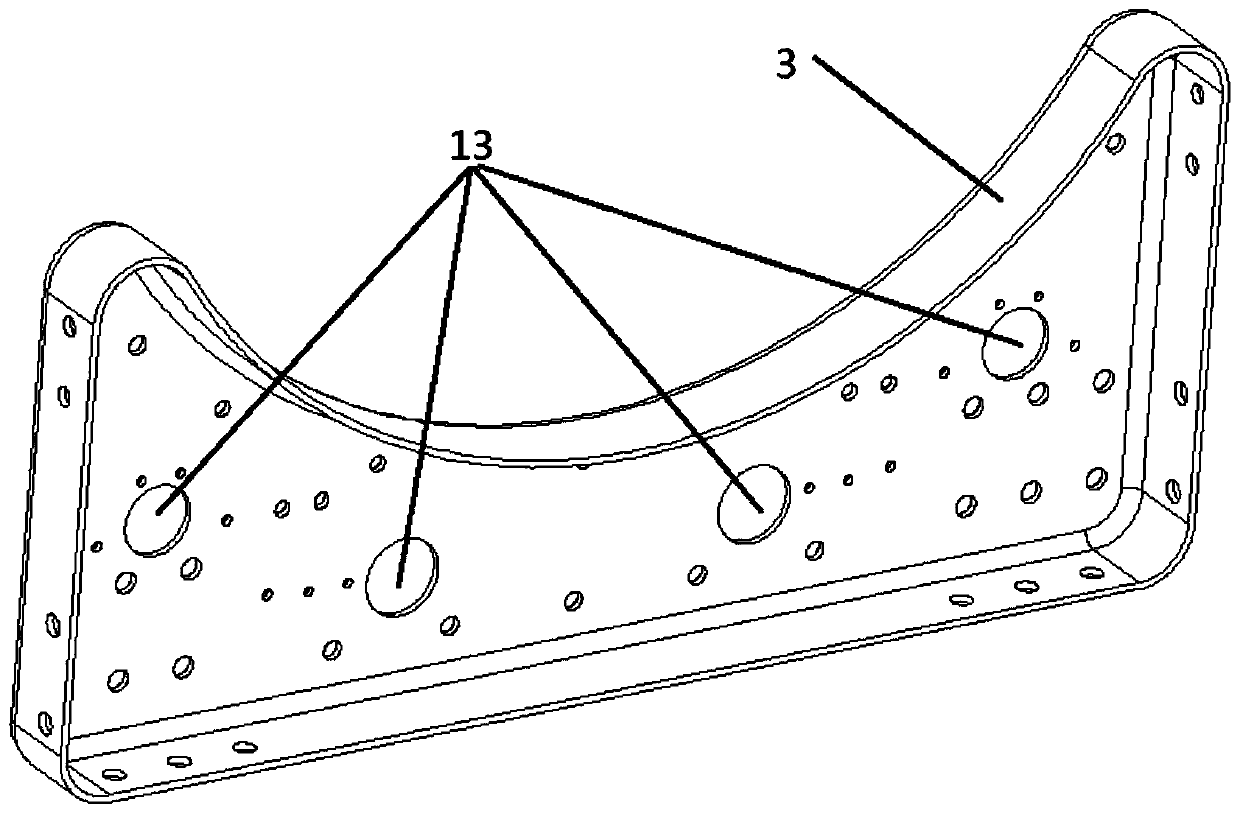

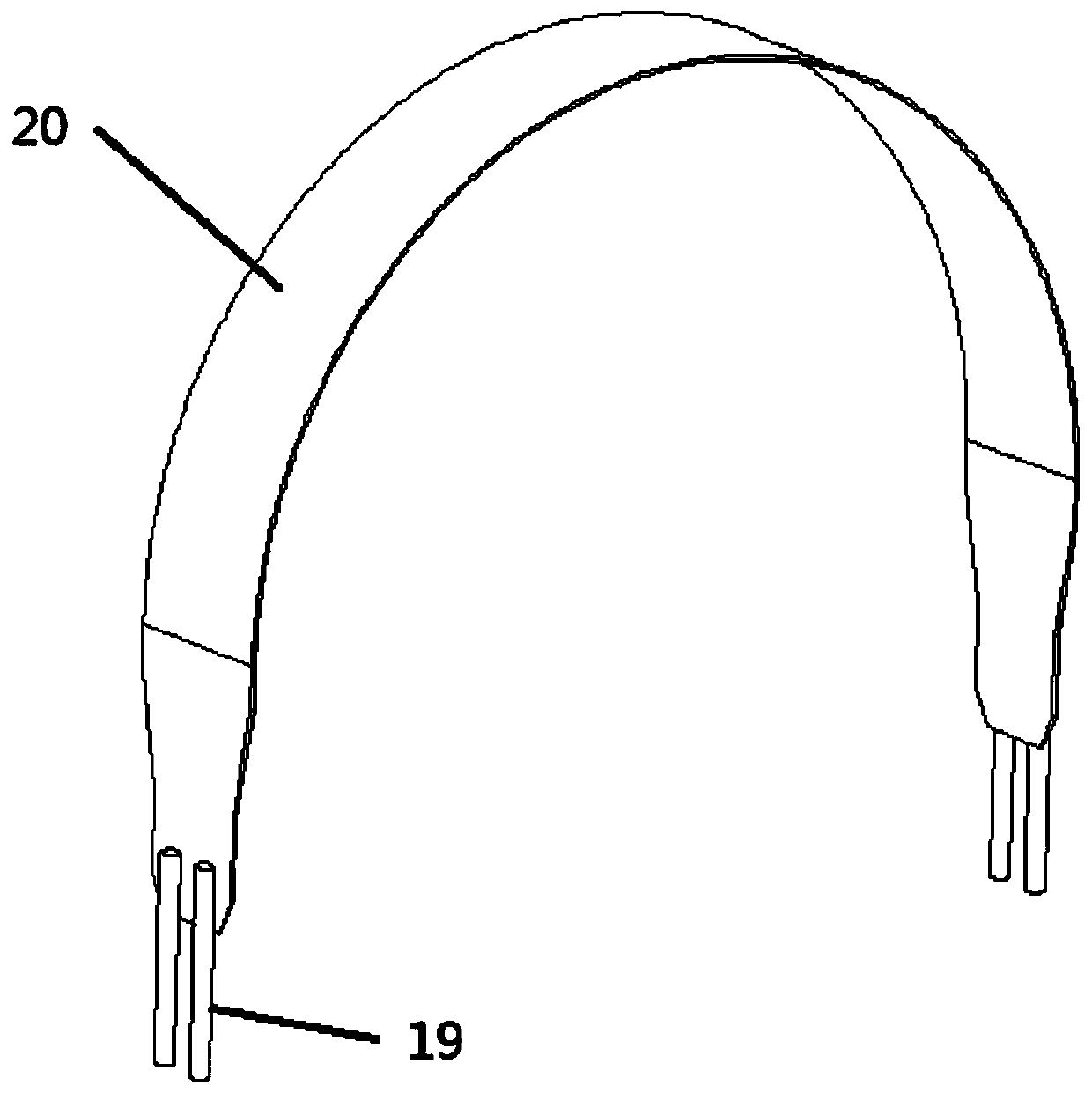

[0020] Figure 1-Figure 4 Show the specific embodiment of the present invention: a commercial vehicle liquefied gas cylinder without bottom beam frame, including two saddles 3 and drawstring assembly 1 detachably connected to the two saddles 3, two saddles The outer sidewalls of the saddle 3 are respectively connected with the upper beam 10 and the lower beam 9 through the self-locking bolt 4 and the self-locking nut 5, and the outer sidewall of the saddle 3 is riveted with the outer arc plate 2, and the saddle 3 It is a press-formed part with a "[" shape and a symmetrical shape. The cross section of the outer arc plate 2 is "L" shaped. An arc-shaped surface on a circular arc surface, the middle part of the outer wall of one of the saddles 3 is also connected with a symmetrical anti-rotation bracket 12 through a self-locking bolt 4 and a self-locking nut 5, and the connection between the anti-rotation bracket 12 and the front end of the liquefied gas cylinder The plates are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com