Punching device for paperboard

A punching device and cardboard technology, which is applied in metal processing and other directions, can solve the problem of waste cardboard detachment, and achieve the effects of avoiding offset, ensuring stability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

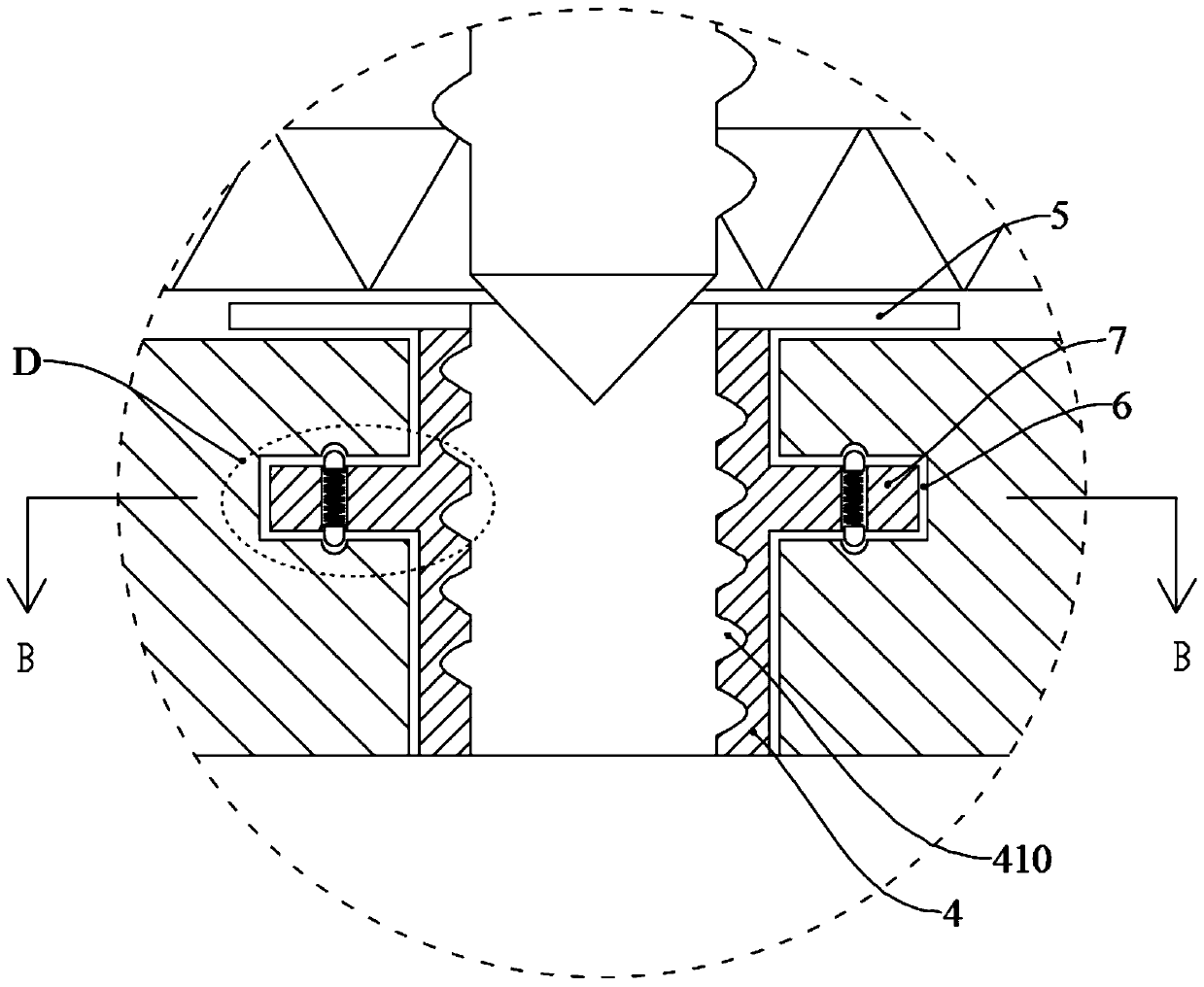

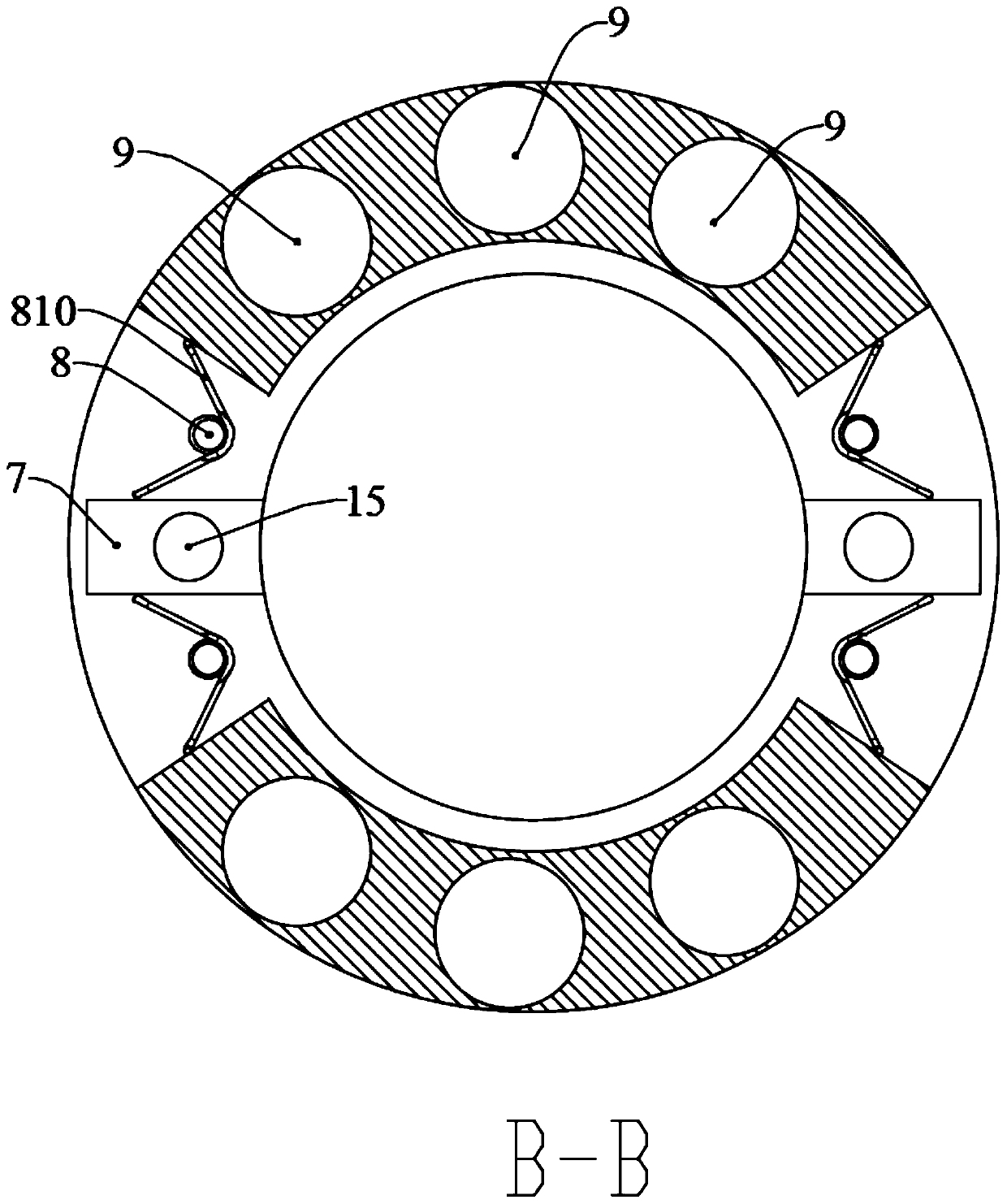

[0033] The cardboard punching device of the present invention comprises a workbench 1, which is provided with a plurality of relief holes 2 through the workbench 1, and a plurality of perforating needles 3 which can be lifted and lowered at the same time are arranged above the workbench 1; the lower ends of any perforating needles 3 The outer wall is spirally provided with reinforcing ribs 310 along the height direction, and a sleeve 4 is arranged in any relief hole 2. The inner wall of the sleeve 4 is provided with a spiral guide groove 410 matching with the reinforcing ribs 310 along the height direction. The upper end extends out of the relief hole 2 and is connected with a plurality of blades 5, the middle outer wall of the relief hole 2 is symmetrically provided with a placement groove 6, and the outer wall of the sleeve 4 is symmetrically connected with a positioning block 7 located in the placement groove 6, any positioning block 7 Both sides are provided with positionin...

Embodiment 2

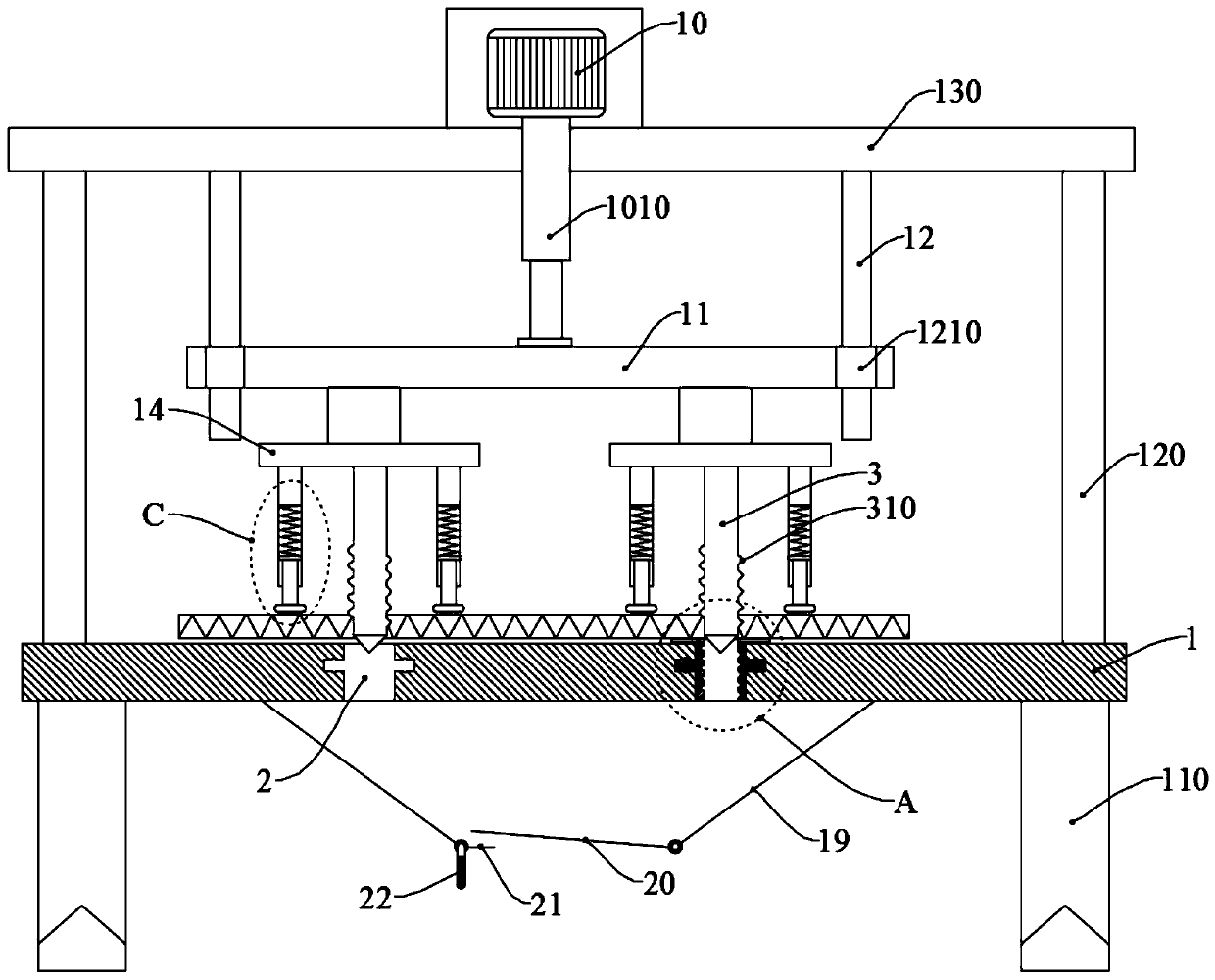

[0036] This embodiment is further optimized on the basis of Embodiment 1 as follows: the lower end of the workbench 1 is provided with a plurality of supporting legs 110, the left and right sides of the upper end of the workbench 1 are provided with support plates 120, and the upper end of the support plate 120 Connected with a placement table 130, the upper end of the placement table 130 is provided with a hydraulic cylinder 10, the telescopic shaft 1010 of the hydraulic cylinder 10 runs through the placement table 130 and is connected with a lifting plate 11, and the lifting plate 11 below is connected with several punching needles 3.

[0037] After adopting the above-mentioned technical scheme, a support plate 120 and a placement platform 130 are provided on the upper end of the workbench 1, and the support plate 120, the placement platform 130 and the workbench 1 are welded or bolted to maintain integrity, and driven by the hydraulic cylinder 10. With the expansion and cont...

Embodiment 3

[0039] This embodiment is further optimized on the basis of Embodiment 2 as follows: the lower end of the placing platform 130 is also provided with a plurality of guide posts 12 , and the lifting plate 11 is provided with a plurality of guide holes 1210 for the guide posts 12 to pass through.

[0040] After the above-mentioned technical scheme is adopted, the stability of the lifting plate 11 during the lifting process is ensured through the function of the guide post 12 and the guide hole 1210, and the deviation of the punching pin 3 during the lifting process is avoided, effectively preventing the punching pin 3 from colliding with the lifting plate. The placement table 130 collides, resulting in damage to the tines 3 and potential safety hazards caused by the damage of the tines 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com