Upper die insert and die for aluminum plate trimming

A technology of inserts and aluminum plates, applied in the field of upper die inserts and molds, can solve problems such as threats to the quality of outer covering parts, and achieve the effects of reducing the amount of aluminum scraps produced, stabilizing the trimming process, and reducing the frequency of cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

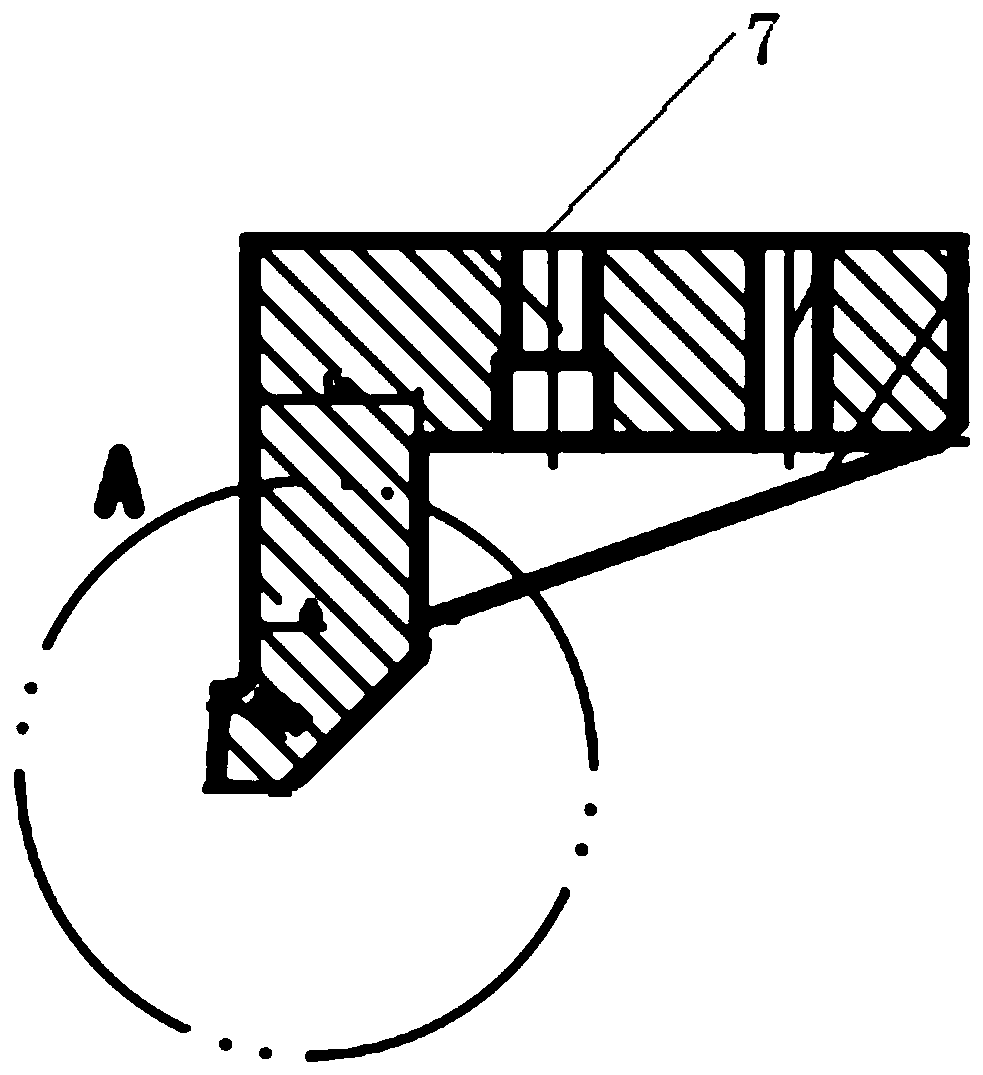

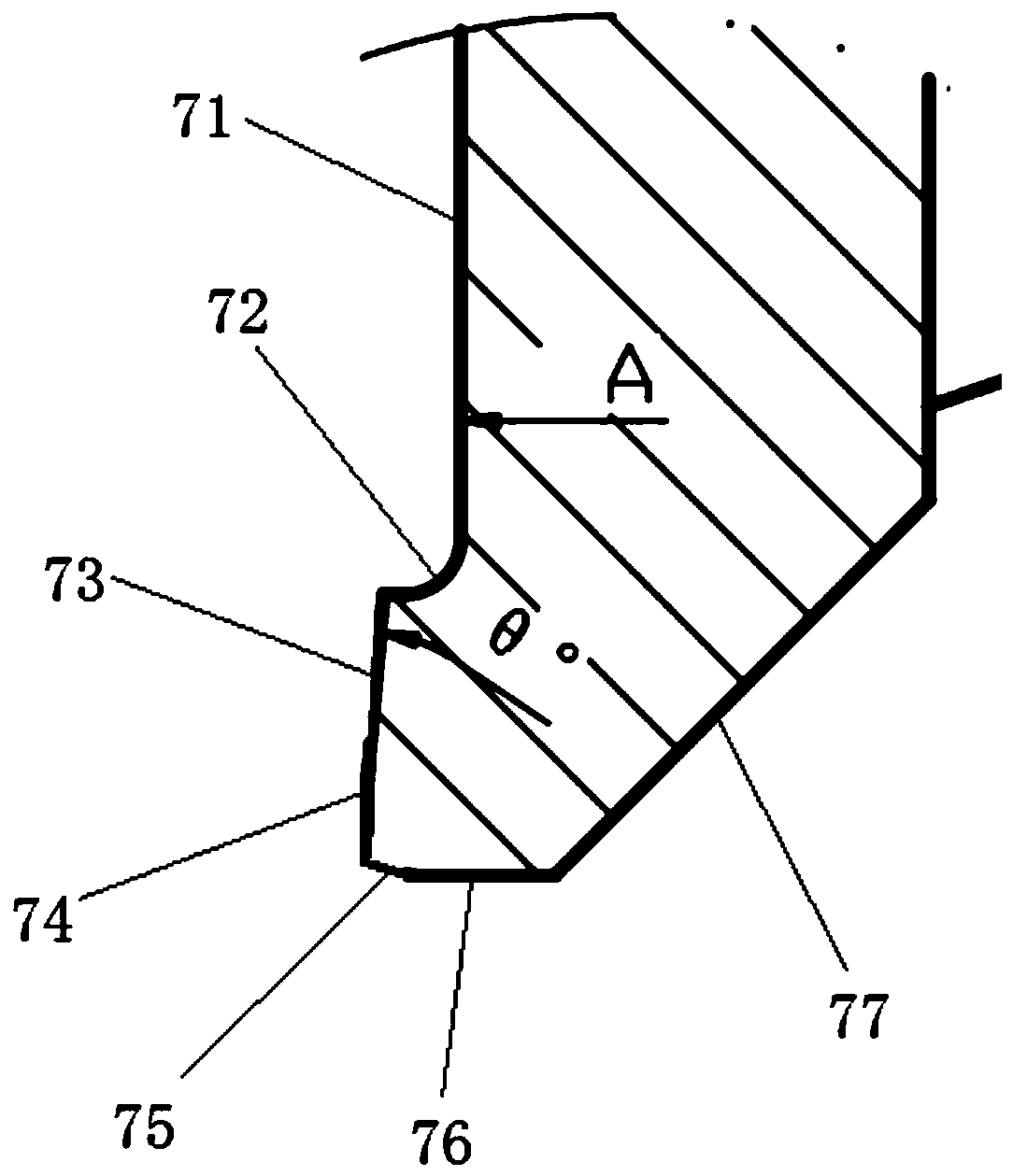

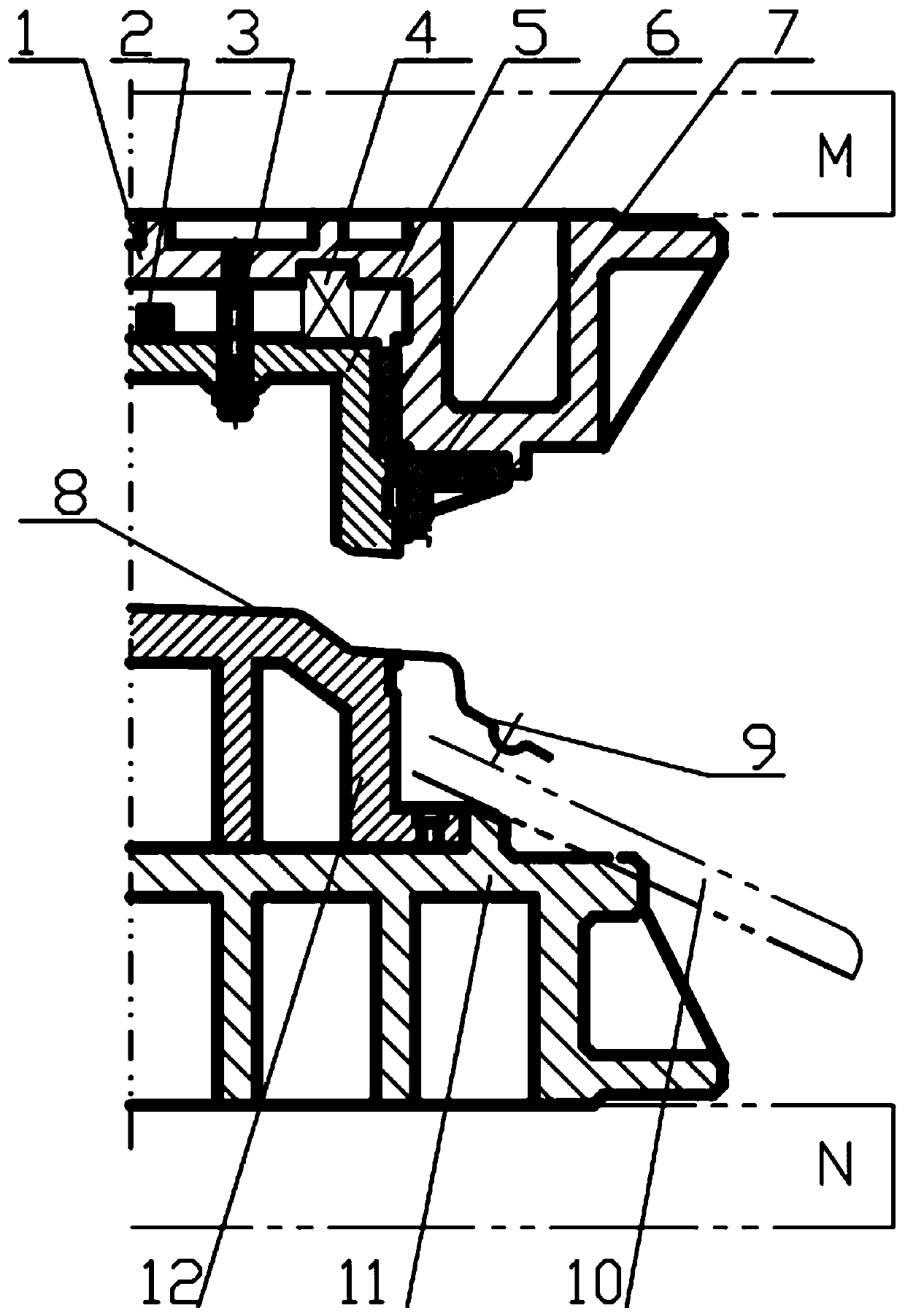

[0021] An upper mold insert used for trimming of aluminum plates. The bottom of the upper mold insert 7 is provided with a connecting vertical edge 71, an arc connecting edge 72, a vertical hypotenuse 73, a vertical edge 74, and a horizontal hypotenuse 75 in sequence. , Horizontal edge 76 and connecting hypotenuse 77, such as figure 1 , 2 As shown, the connecting vertical side 71 and the connecting hypotenuse 77 are connected to the upper part of the upper mold insert 7, the connecting vertical side 71 and the vertical side 74 are parallel and in a vertical direction, and the horizontal side 76 is perpendicular to the vertical side 74, In addition, the horizontal side 76 is in the horizontal direction, and the inclination direction of the vertical hypotenuse 73 and the horizontal side 76 are located on the same side of the vertical side. Among them, the horizontal span between the vertical side 74 and the connecting vertical side 71 is 5 mm, the vertical span between the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com