Secondary smashing extruder for straw and method

A technology of extrusion extruder and secondary pulverization, which is applied in the field of agricultural machinery and can solve problems such as blockage and insufficient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

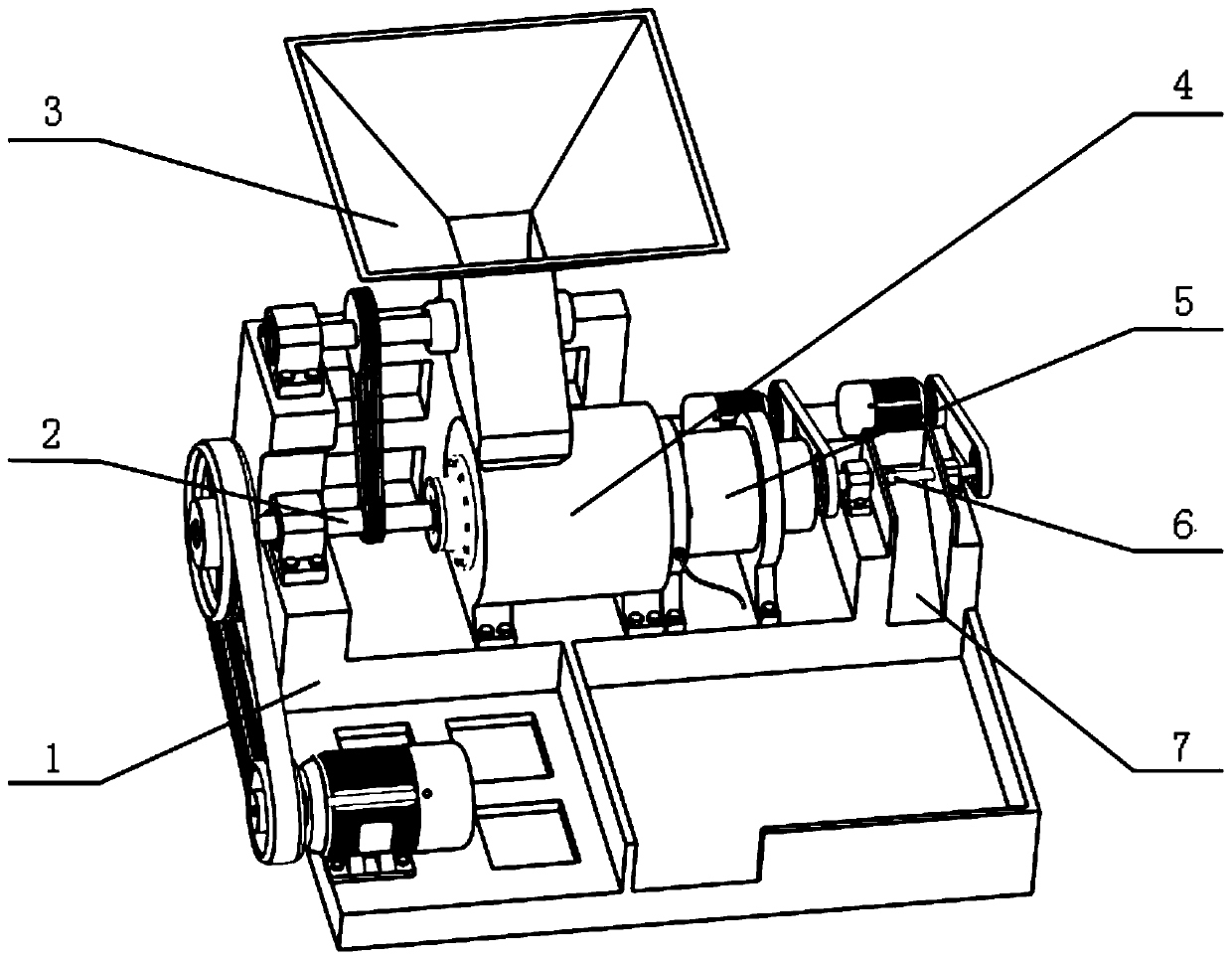

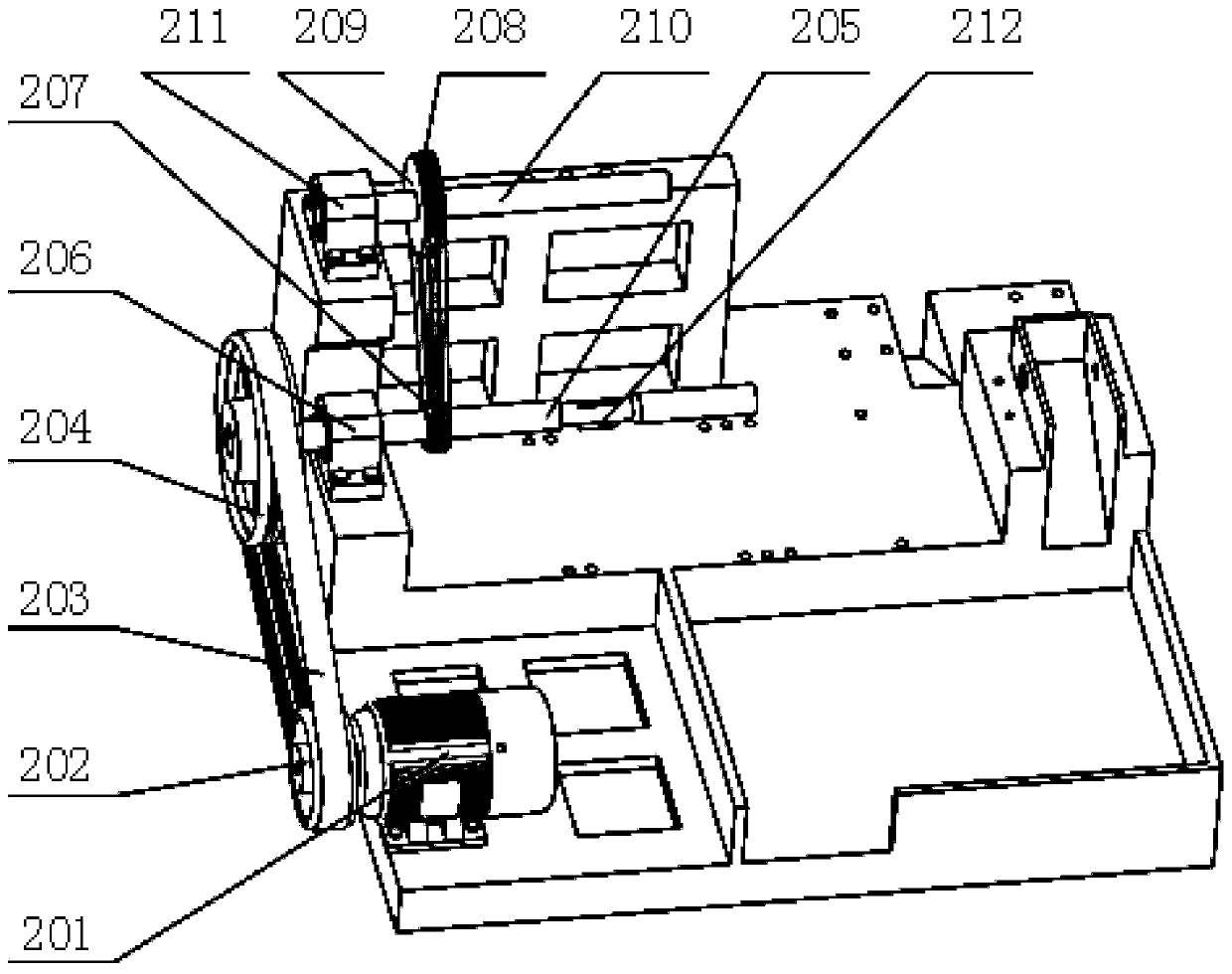

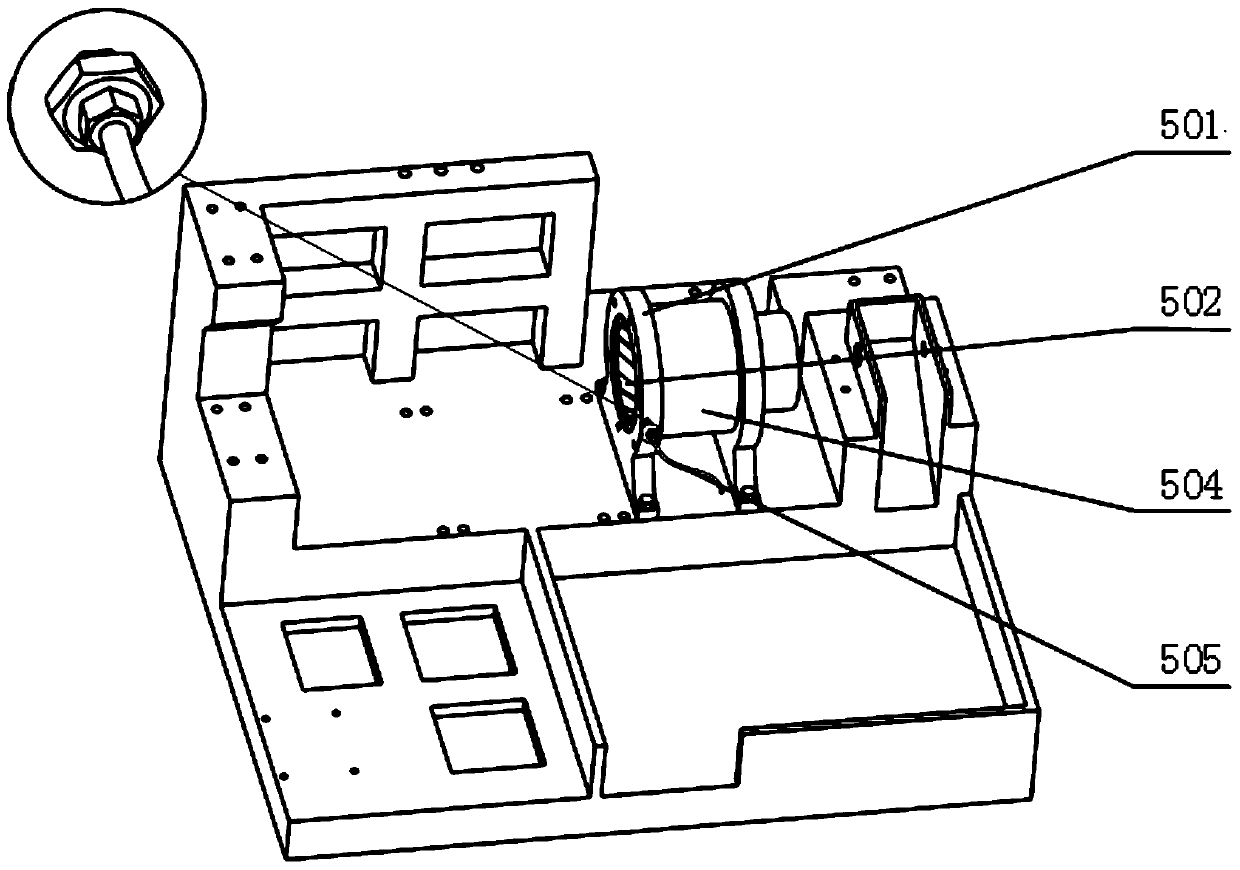

[0036] like figure 1 As shown, it includes frame 1, transmission system 2, feeding system 3, pulverizing and pushing system 4, high temperature and high pressure extruding system 5, discharging system 6, and collecting system 7, wherein the transmission system 2 is fixed on the frame by bolts On the left side of 1, the pulverizing and pushing system 4 is fixed by bolts in the middle of the groove of the installation frame 1 and is located on the right side of the transmission system 2, and the feeding system 3 is fixed by bolts on the square-shaped bracket behind the frame 1 , and located above the pulverizing and pushing system 4, the high-temperature and high-pressure extruding system 5 is fixedly installed on the right side of the groove of the frame 1 by bolts, and is located on the right side of the pulverizing and pushing system 4, and the discharge system 6 is fixedly installed on the On the right side of the frame 1, the material collection system 7 is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com