Spicy fresh cheese and preparing method thereof

A spicy and cheese technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problem of low acceptance, achieve the effect of improving taste and nutritional value, high acceptance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

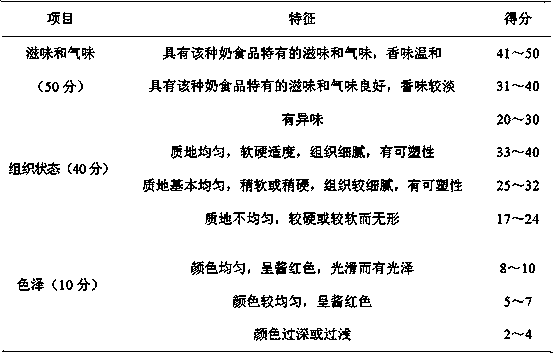

[0031] Embodiment 1-6 spicy fresh cheese

[0032] Embodiments 1-6 are respectively a kind of spicy fresh cheese, wherein, the rennet in the present embodiment 1-6 adopts the rennet derived from Aspergillus, and the spicy seasoning consists of chili powder, star anise powder, orange peel powder, cumin Powder, garlic powder, ginger powder, white pepper powder, bay leaf powder, licorice powder are added according to the mass ratio of 24:4:4:4:4:2:2:1:1, the specific components, mass parts, etc. of each raw material The parameters are shown in Table 1:

[0033] Table 1 Embodiment 1-6 raw material composition

[0034] .

Embodiment 7

[0035] Embodiment 7 A kind of preparation method of spicy fresh cheese

[0036] This embodiment is the preparation method of spicy fresh cheese in the embodiment 1-6, and the raw material components and the proportion relationship are composed of any one of the embodiments 1-6, and the preparation method is carried out according to the following steps:

[0037] a1. Standardize the milk and pasteurize it to obtain sterilized milk A1;

[0038] a2. After cooling the sterilized milk A1 to 30°C, add calcium chloride aqueous solution, stir for 2 minutes at a speed of 900r / min, add Lactobacillus paracasei N1115 and rennet, mix well, and place in a 30°C incubator. Ferment for 1.5 hours to obtain curd B1;

[0039] a3. After cutting the curd B1 into cubes with a side length of 1.1 cm, let it stand for 5 minutes, and then stir for 18 minutes at a rotating speed of 75 r / min to obtain the curd C1;

[0040] a4. Add curd C1 to milk with a mass of 18% hot water at 50°C to obtain curd partic...

Embodiment 8-13

[0045] The preparation method of embodiment 8-13 spicy fresh cheese

[0046] Embodiments 8-13 are respectively a preparation method of spicy fresh cheese, and their preparation steps are all the same as in Example 7, except that the operating parameters in the preparation process are different, and the specific operating parameters are as shown in Table 2:

[0047] Table 2 Example 8-13 preparation process operating parameters

[0048] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com