Chip cleaning container on semiconductor lapping plate and use method thereof

A chip cleaning and grinding plate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the chip interface cleaning process on the grinding plate cannot be performed, so as to improve batch production efficiency, facilitate loading and unloading, and prevent The effect of scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

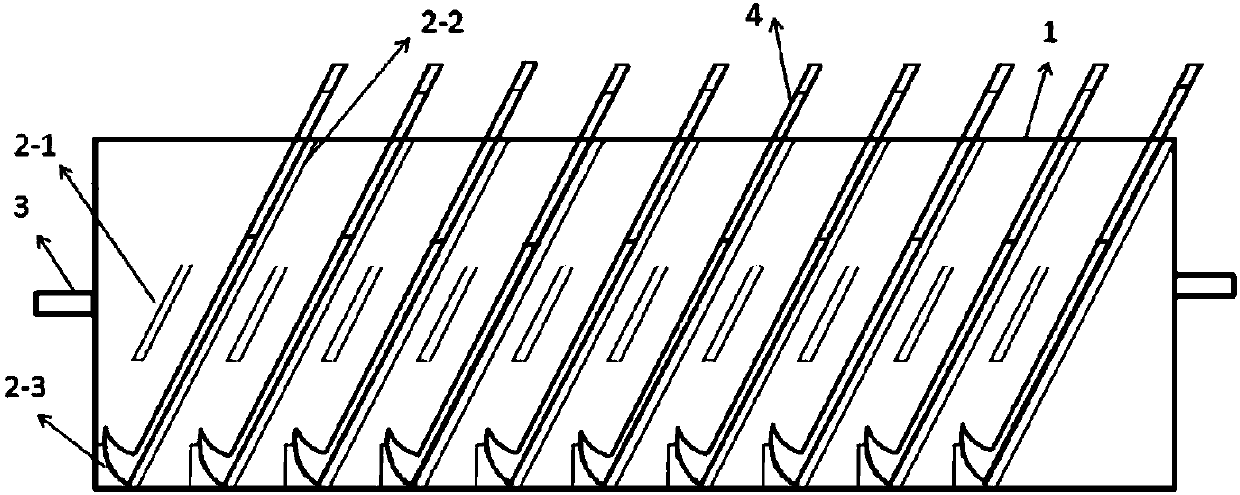

[0049] A chip cleaning container on a semiconductor grinding board, including a container body, the container body is a rectangular cavity with an open top, and ten slot units are arranged inside the container body, and a carrier platform is arranged in the slot unit, such as figure 1 shown.

[0050] The card slot unit includes a card slot front stop, a card slot back stop, and a card slot bottom stop. The number of the card slot front stop and the card slot back stop in a card slot unit is two, and the card slot front stops are arranged symmetrically on the container body. On the inner wall of the container, the back stop of the card slot is symmetrically arranged on the opposite inner wall where the front stop of the card slot is located, and the bottom stop of the card slot is arranged at the bottom of the container body. Both the front block of the card slot and the rear block of the card slot are strip-shaped rectangular blocks.

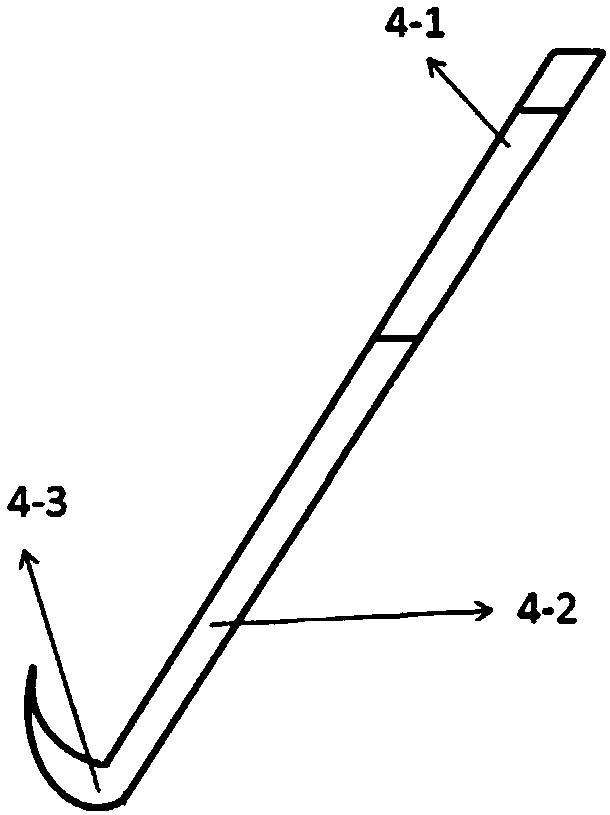

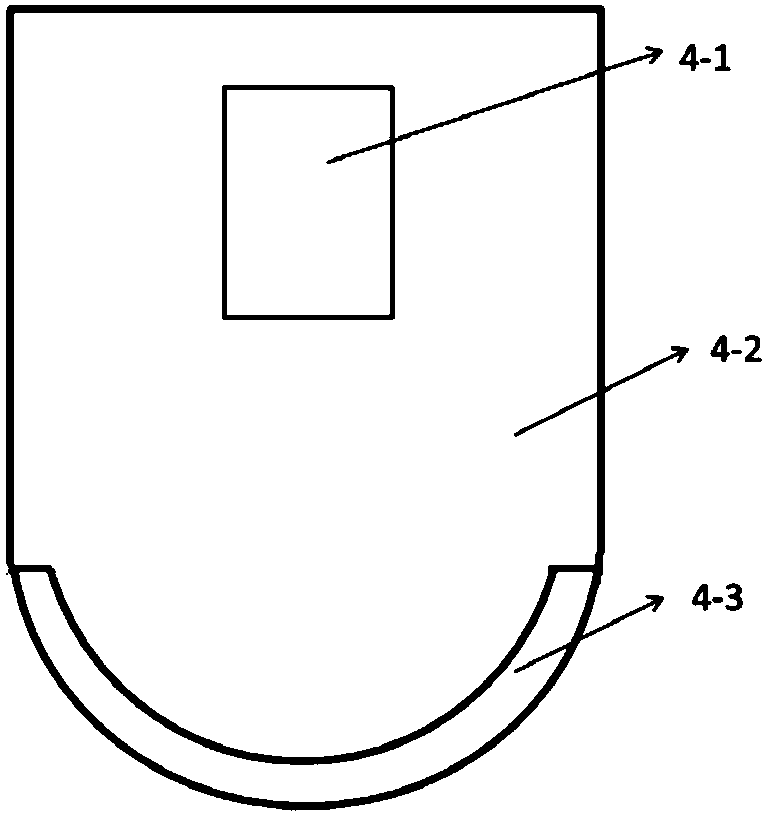

[0051] The carrier table includes the ca...

Embodiment 2

[0054] A chip cleaning container on a semiconductor grinding board, the structure of which is as described in Embodiment 1, the difference is that a container handle is provided at opposite ends of the container body. The handle of the container is arranged on the outside of the side wall of the short side of the rectangle of the container body, and the front stopper and the back stop of the card slot are arranged on the inside of the side wall of the long side of the rectangle of the container body.

Embodiment 3

[0056] A chip cleaning container on a semiconductor grinding board, the structure of which is as described in Embodiment 1, the difference is that the length of the stopper at the front stop of the card slot is shorter than the length of the stopper at the back stop of the card slot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com