A test method for troubleshooting gas water heater software abnormalities

A gas water heater and testing method technology, applied in software testing/debugging, instrumentation, error detection/correction, etc., can solve the problems of cracking down on work enthusiasm, product impact, long test cycle, etc., to shorten the test cycle, narrow the fault range, The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

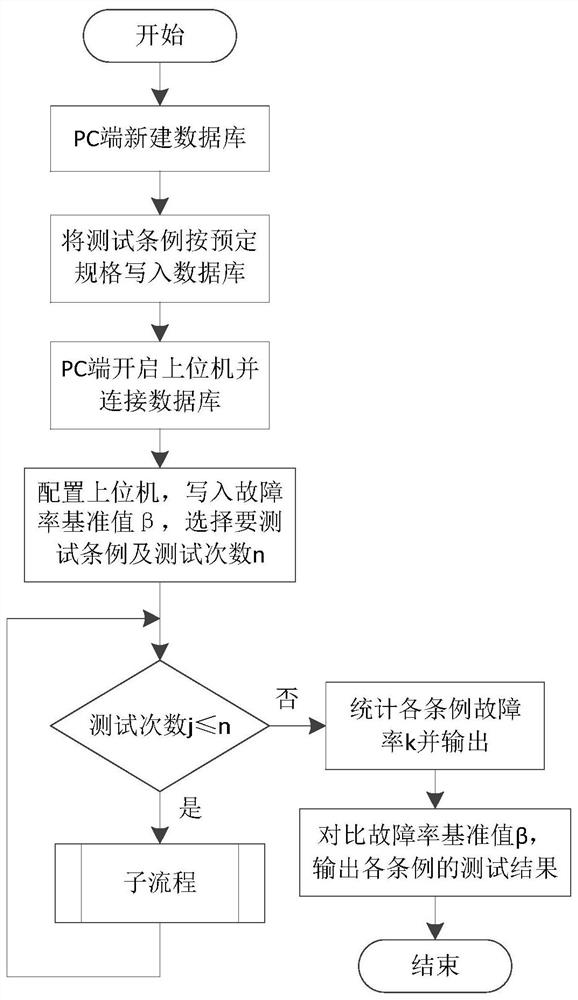

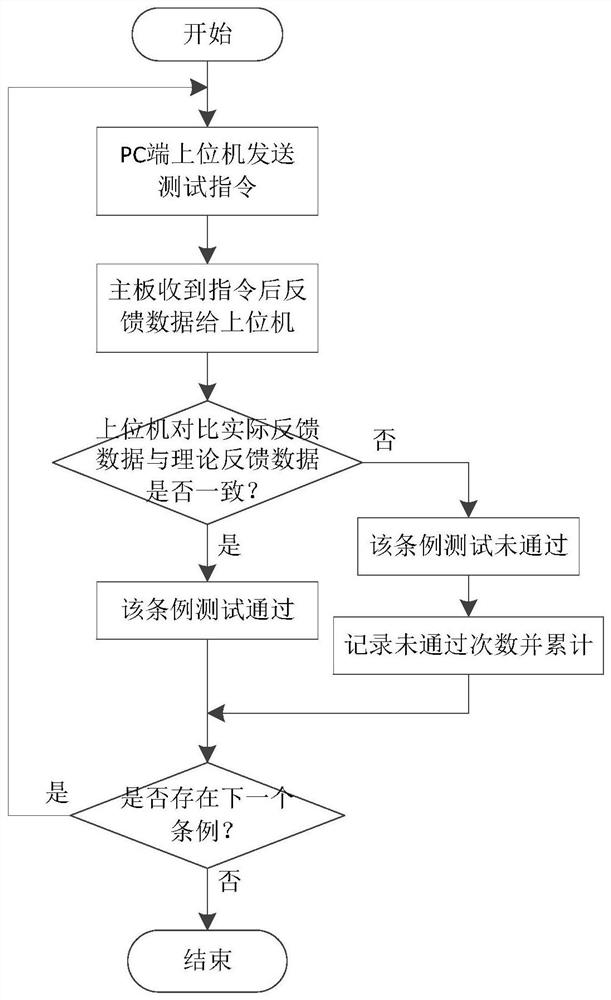

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] Such as Figure 1-2 As shown, this embodiment relates to the troubleshooting of gas water heaters, mainly judging a series of faults that occur during the testing process of gas water heaters, and eliminating the faults of the software itself.

[0033] In the process of gas water heater design and development, the software is reproducible. Usually, once the software part is abnormal, every gas water heater installed with the software will have an abnormality, while the hardware is different, even if it is the same hardware part structure, due to Affected by the processing precision and assembly precision in the production process, each gas water heater installed with the hardware part structure will have different failures when it is finally used. Therefore, in view of the reproducibility characteristics of the software, this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com