Prediction control method and system for magnetic levitation system

A technology of predictive control and magnetic levitation, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of large online calculation amount and difficulty in meeting real-time requirements, achieving accuracy without loss, and less online calculation amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

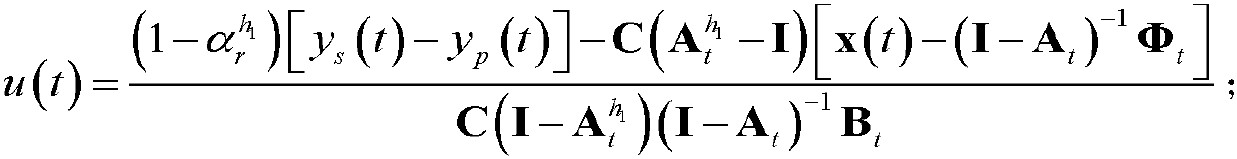

Method used

Image

Examples

Embodiment Construction

[0035] The structure attachment of the magnetic levitation ball system of the present invention figure 1 As shown, this is a single-degree-of-freedom system that can only control the movement of the steel ball in the up and down direction. No. 1 is steel ball, No. 2 is electromagnetic winding, No. 3 is LED light source, No. 4 is photoelectric panel, No. 5 is processing circuit, No. 6 is electromagnetic winding drive circuit, No. 7 is A / D converter, No. 8 is D / A converter, No. 9 is PC computer. The working process is called: the PC outputs the control voltage digital signal, and the analog signal is transmitted to the electromagnetic winding drive circuit after being converted by the D / A converter. Under the action of the current, the electromagnetic winding generates an electromagnetic field around the winding through electromagnetic induction, so as to The steel ball in the magnetic field forms an electromagnetic induction force F, which moves the steel ball upward. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com