In-hole installation and recovery device for micro-seismic sensor on the basis of hot melt adhesive

A technology of microseismic sensors and recovery devices, which is applied in the direction of seismic signal receivers, etc., can solve problems such as high cost, wear and damage of sensors and cables, and strict production process requirements, and achieve easy operation, installation and recovery, structure and The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

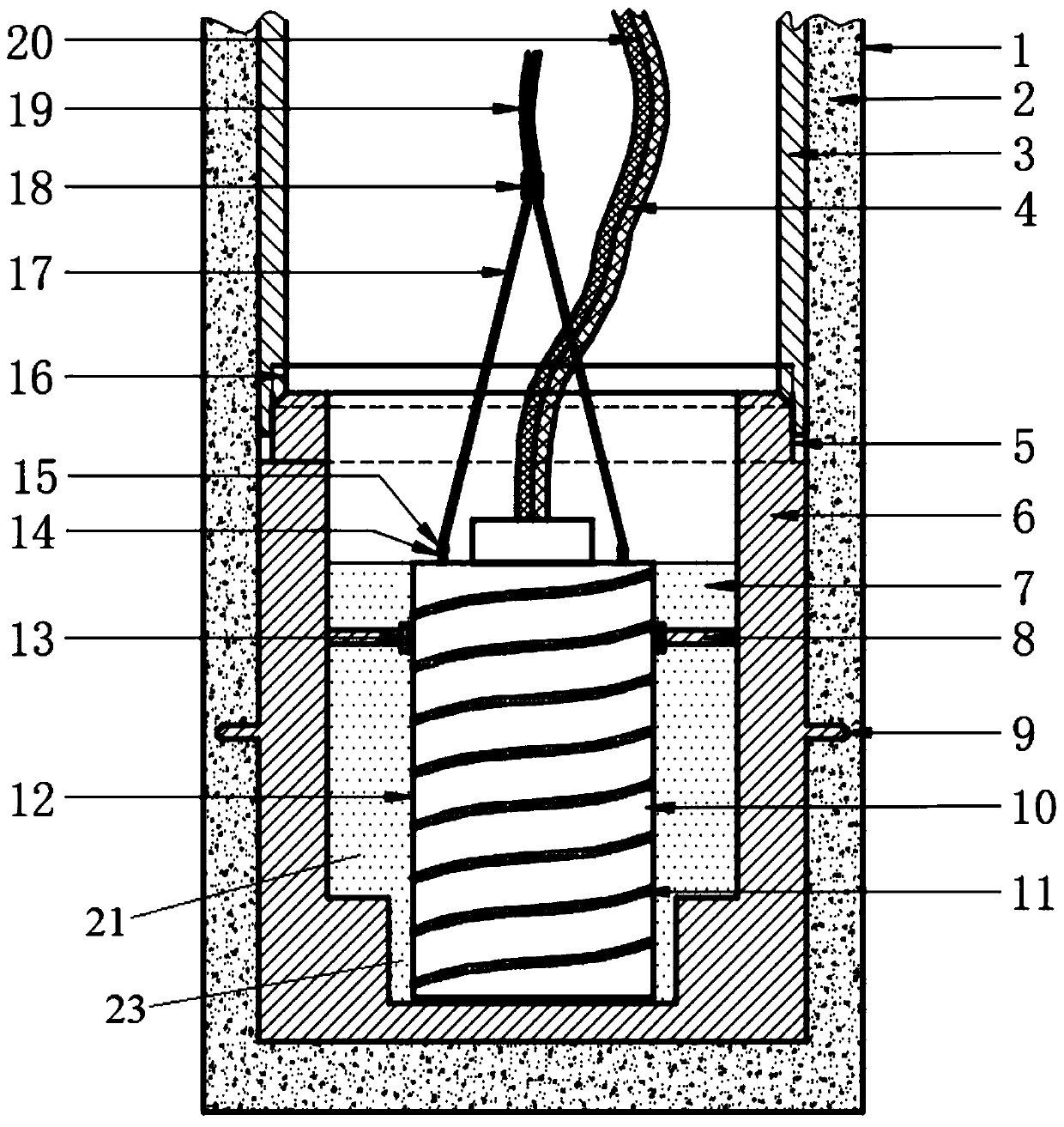

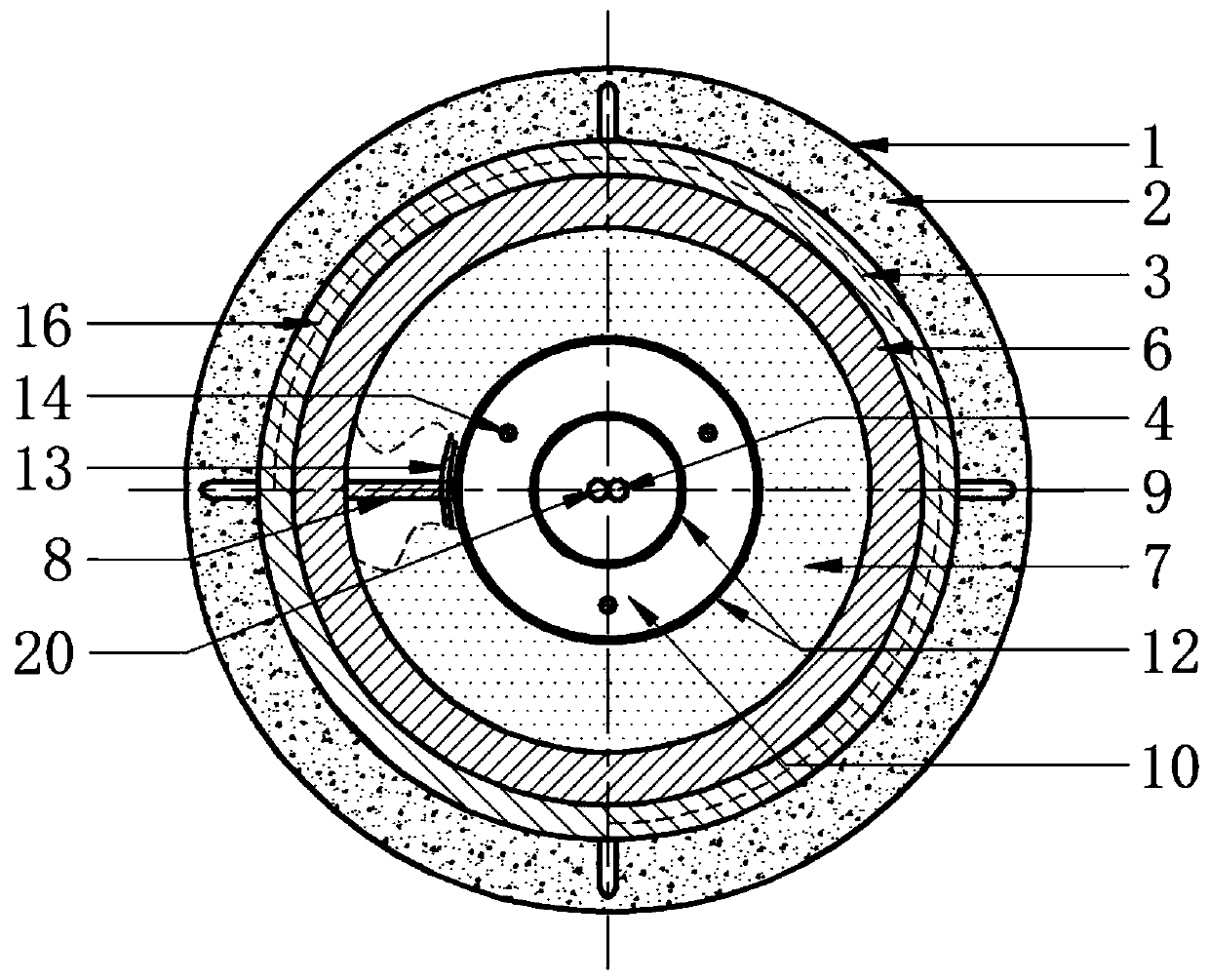

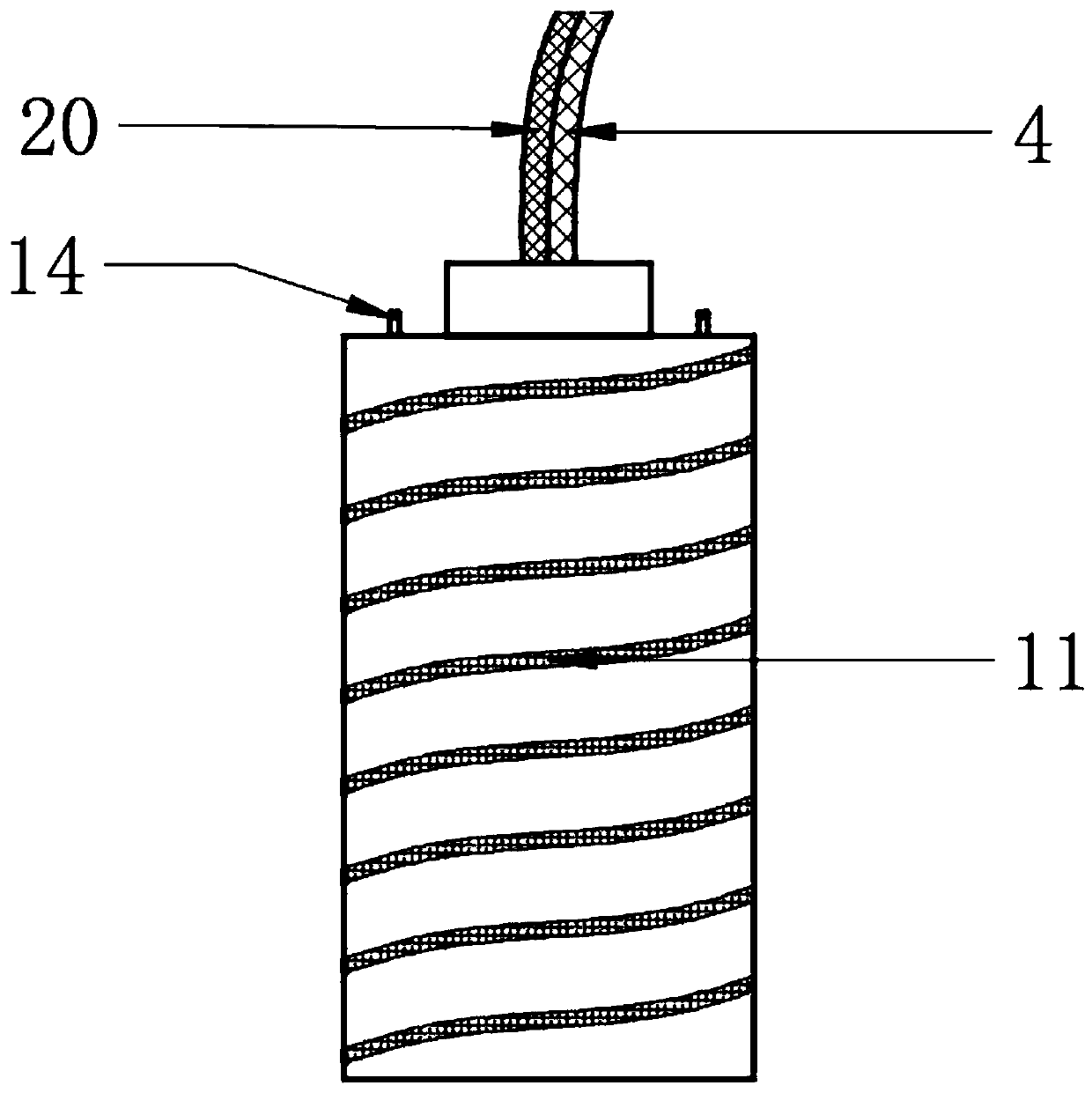

[0044] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0045] Such as Figure 1 to Figure 9 As shown, a recovery device installed in the hole of a microseismic sensor based on hot melt adhesive includes a sleeve 3, a base 6, a microseismic sensor 10, a fixed wire rope 17, a lifting wire rope 19 and a heat insulation layer 12, and the lifting wire rope 19 and the fixed wire rope 17 Connection, the fixed wire rope 17 is connected to the top of the microseismic sensor 10, the bottom of the microseismic sensor 10 and the surrounding wrap the heat insulation layer 12, the base 6 is provided with an installation groove 21 for accommodating the microseismic sensor 10, and the center of the bottom of the installation groove 21 is provided with a The positioning groove 23 of the microseismic sensor 10, the top of the mounting groove 21 is provided with a fixing ring 13 for positioning the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com