Test device for metal material creep under in-reactor radiation environment

A metal material and testing device technology, which is applied to measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure. Feasible and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Experiments in the core fuel assembly guide tube of a pressurized water reactor nuclear power plant

[0030] like Figure 5 As shown, a creep test device of the present invention is placed at the lower part of the choke rod 5, wherein the mandrel 2, the first end plug 3, and the choke rod 5 are formed into an integrated structure by machining. The upper structure of the choke rod 5 is the same as the choke rod of the conventional PWR choke plug assembly. After the integrated rod-shaped structure formed by the creep test device of the present invention and the choke rod 5, the conventional choke rod can be replaced.

[0031] The length and diameter of the choke rods 5 are kept the same as those of conventional choke rods, so that when used in the stack, the impact on the coolant flow path is expected to be small compared to the conventional choke rods, which can be compared with conventional choke rods. The flow stopper remains fairly effective.

[0032] The thin-wall...

Embodiment 2

[0036] Testing in the test reactor containment chamber

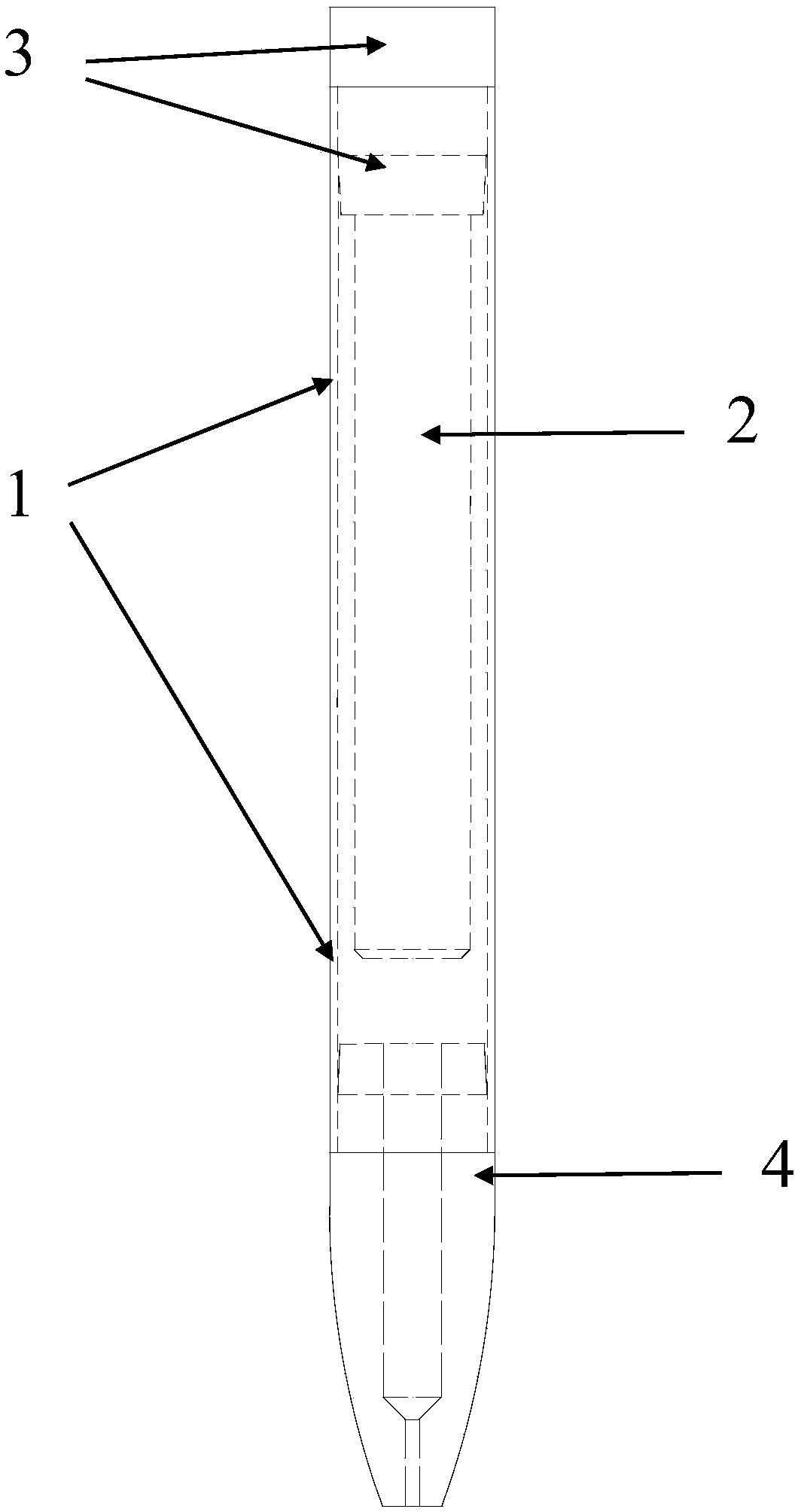

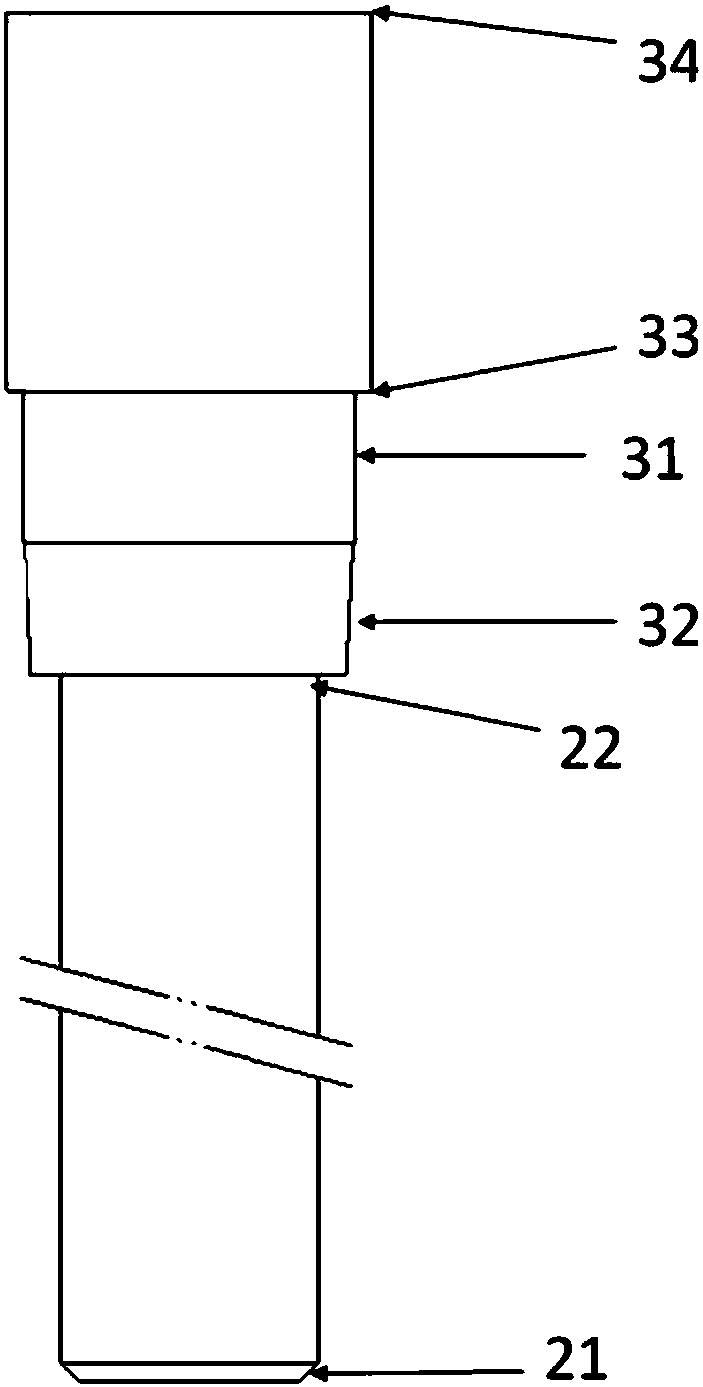

[0037] like Image 6 As shown, a metal material creep test device of the present invention is composed of a thin-walled round tube 1 , a mandrel 2 , a first end plug 3 , and a second end plug 4 . The second end plug 4 is slightly different from that in Embodiment 1, and the end portion is flat, so as to save the space of the irradiation test sealing chamber.

[0038] The thin-walled circular tube 1 has a wall thickness of 0.57 mm, a length of 100 mm, and an outer diameter of 9.5 mm. The mandrel is 5.36mm in diameter and 85mm in length. The gap between the mandrel and the inner wall of the round tube is 1.5mm. According to the needs of the test, the pre-filled helium gas pressure is between 0.1MPa and 7MPa.

[0039] The assembly process can refer to Example 1. During the test, with the help of the advanced deformation measurement tools of the test reactor, the real-time measurement of the creep deformation during the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com