Large turntable bearing assembly workbench

A technology for assembling workbenches and slewing bearings, which is applied to bearing assembly, bearing components, shafts and bearings, etc., can solve the problems of high difficulty in transportation, large space occupation, and crudeness, etc., and achieves improved fitting accuracy, simple structure, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the structure and function of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

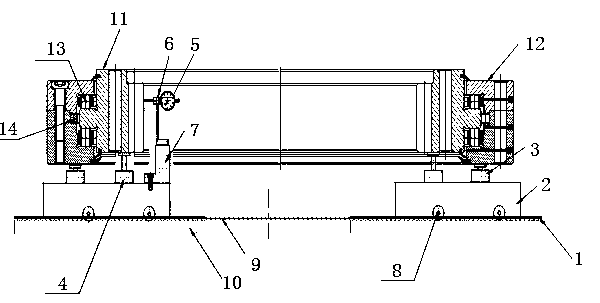

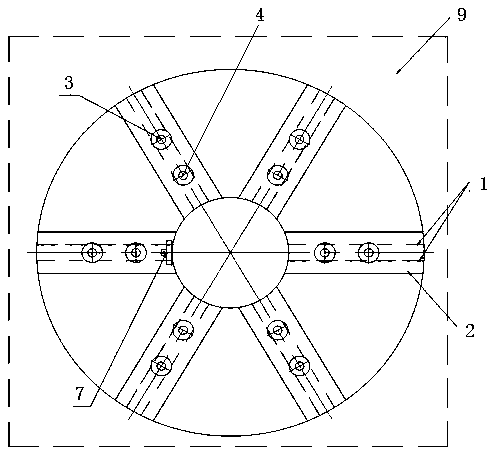

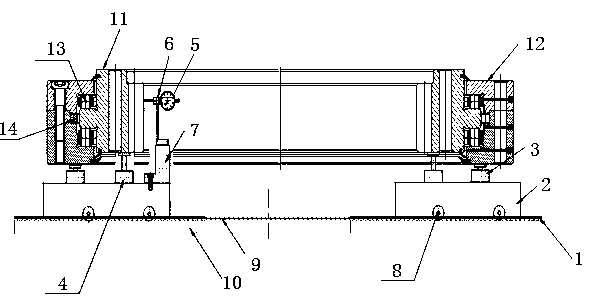

[0019] Refer to attached Figure 1-2 , a large-scale turntable bearing assembly workbench, including six guide rails 1, a mobile box 2 and six supporting hydraulic jacks 3; the six guide rails 1 are evenly distributed along the circumferential direction on the ground, and the angle formed by each two guide rails is 30° , each guide rail 1 is provided with a moving box 2, and each moving box 2 is provided with a supporting hydraulic jack 3, and the supporting hydraulic jack 3 is in contact with the end surface of the bearing outer ring and supports the bearing outer ring 12, Six supporting hydraulic jacks 3 are set to start hydraulically synchronously and are equipped with a small hydraulic station. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com