Concrete curing agent

A technology of concrete curing agent and initiator, applied in the field of concrete curing agent, can solve problems such as peeling, temperature influence, cracking, etc., and achieve the effects of good durability, increased strength and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

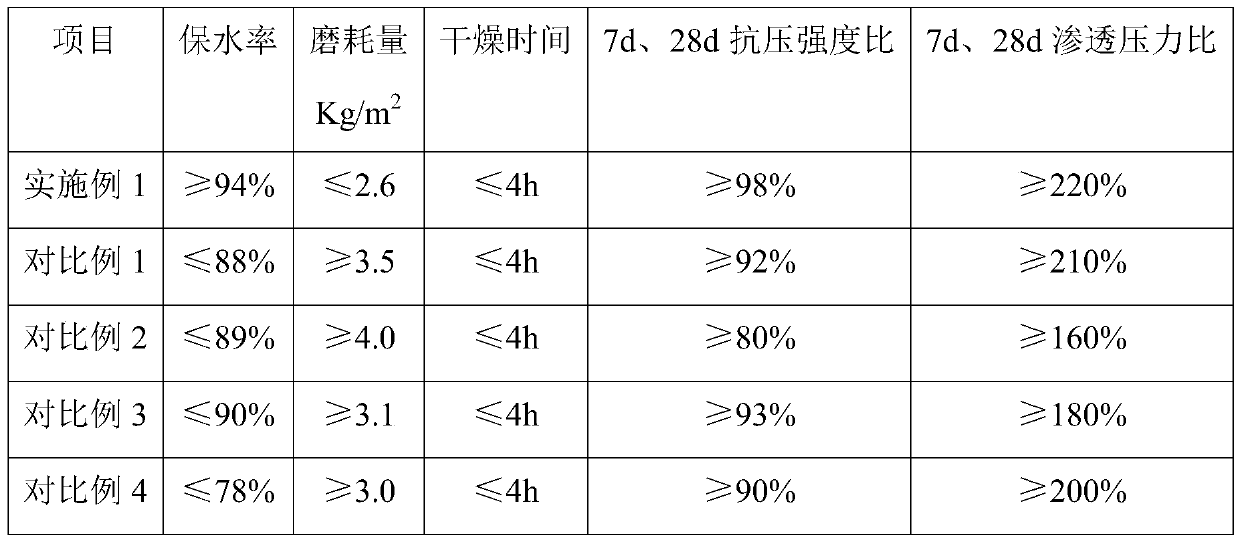

Examples

Embodiment 1

[0027] Step 1, prepare polymer emulsion, add 20 times water of emulsifier weight to emulsifier by weight parts of inner core monomer, external crystal nucleus, initiator, emulsifier, add inner core monomer and stir at high speed for 30min, stirring speed 1600r / min, then add the first initiator, continue stirring at high speed for 120min, stirring speed 1600r / min; then add the external crystal nucleus and continue stirring for 20min, stirring speed is 600r / min, then add the second initiator and continue stirring 360min to get the polymer emulsion, the stirring speed is not higher than 300r / min; wherein the weight ratio of the first initiator and the second initiator is 20:1;

[0028] Wherein the macromolecular emulsion comprises an inner core monomer, an external crystal nucleus, an initiator and an emulsifier, and the internal core monomer comprises 1 part of styrene, 1 part of vinyl acetate and 5 parts of methyl acrylate in parts by weight; the external crystal nucleus The co...

Embodiment 2

[0067] Step 1. Prepare a polymer emulsion. Weigh the inner core monomer, external crystal nucleus, initiator, and emulsifier in proportion, add water 100 times the weight of the emulsifier to the emulsifier, and stir at high speed for 20 minutes after adding the inner core monomer. 600r / min, then add the first initiator, continue to stir at a high speed for 60min, the stirring speed is 500r / min; then add the external crystal nucleus and continue stirring for 10min, the stirring speed is 300r / min, then add the second initiator to continue Stir for 120min to obtain a polymer emulsion, and the stirring speed is not higher than 300r / min; wherein the weight ratio of the first initiator and the second initiator is 10:1; the inner core monomer and the outer crystal nucleus are at different stirring speeds, Form a layered film structure to increase the continuity and durability of the curing agent.

[0068] Wherein the polymer emulsion comprises inner core monomer, external crystal nu...

Embodiment 3

[0073]Step 1. Prepare polymer emulsion, weigh the inner core monomer, external crystal nucleus, initiator and emulsifier in proportion, add water 12 times the weight of the emulsifier to the emulsifier, add the inner core monomer and stir at high speed for 23 minutes, the stirring speed 800r / min, then add the first initiator, continue to stir at a high speed for 100min, the stirring speed is 800r / min; then add the external crystal nucleus and continue stirring for 15min, the stirring speed is 400r / min, then add the second initiator to continue Stir for 260min to obtain a polymer emulsion, and the stirring speed is not higher than 300r / min; wherein the weight ratio of the first initiator and the second initiator is 15:1; the inner core monomer and the outer crystal nucleus are at different stirring speeds, Form a layered film structure to increase the continuity and durability of the curing agent.

[0074] Wherein the polymer emulsion comprises inner core monomer, external crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com