High-efficiency pig manure fermentation method

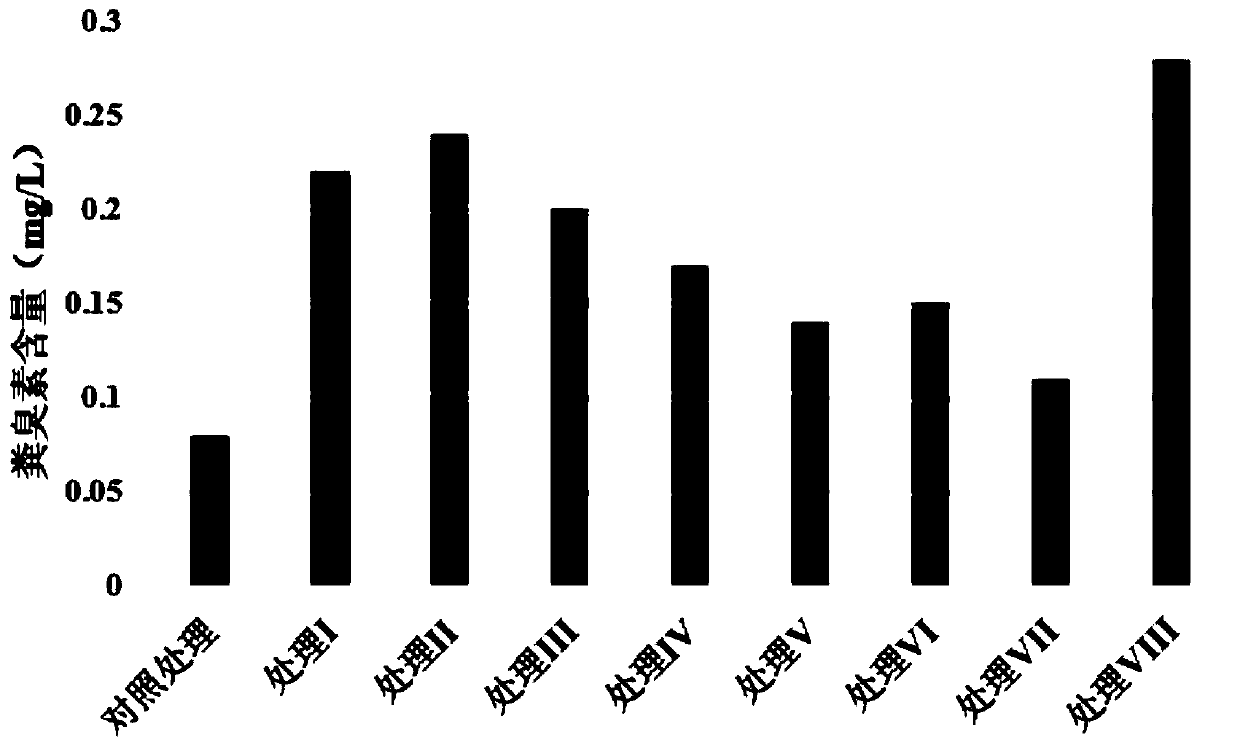

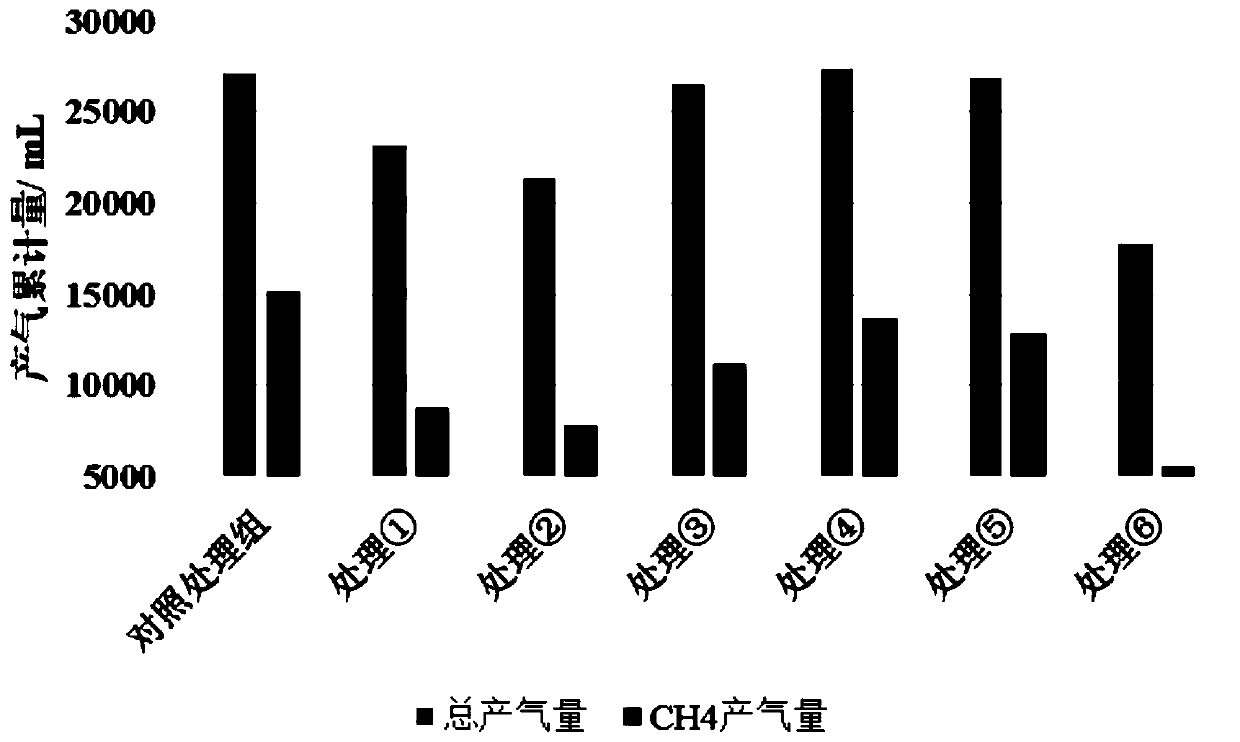

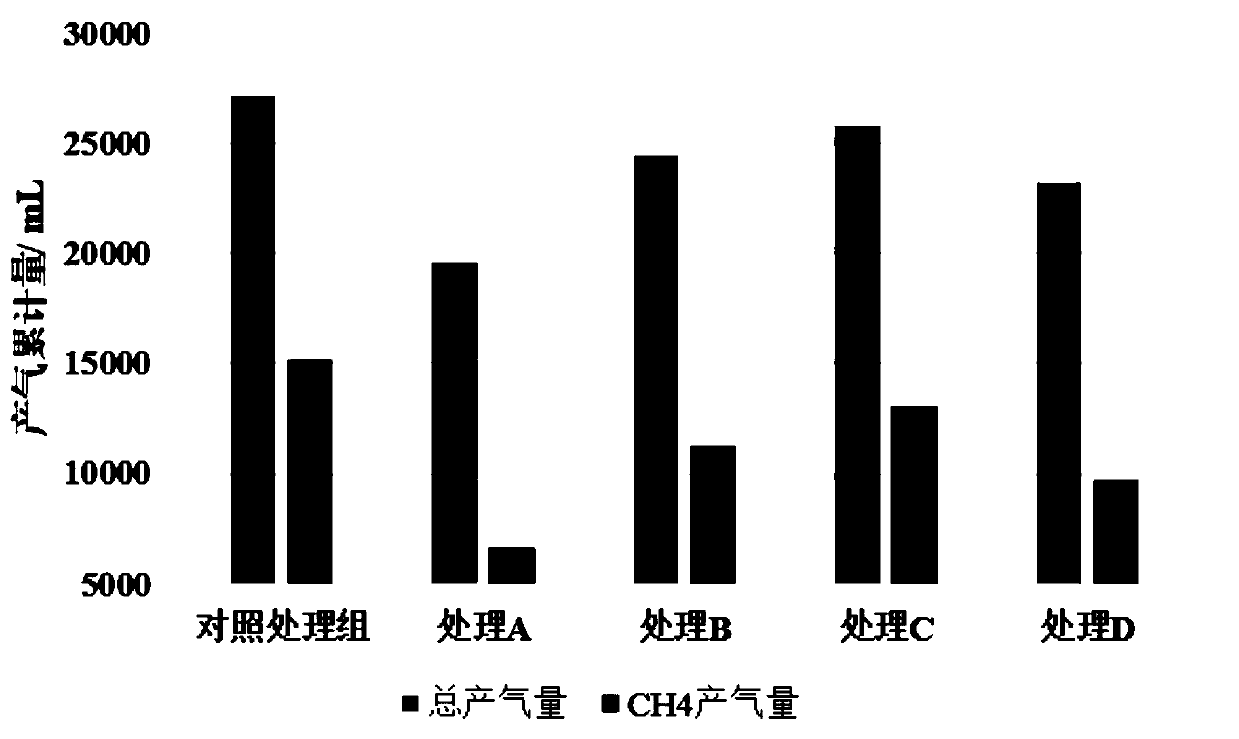

A fermentation method and pig manure technology, applied in the field of animal waste fermentation, can solve the problems of high cellulose and lignin content, low gas production efficiency, incomplete fermentation, etc., to improve metabolic capacity, reduce skatole content, and early the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment realizes the decomposing fermentation of pig manure according to the following steps:

[0022] (1) According to the ratio of Bacillus: Yeast: Actinomycetes = 1:1:2, the effective number of viable bacteria in the composite bacterial agent is not less than 10. 8 CFU / mL;

[0023] (2) according to amylase: the weight ratio of protease=3:1 prepares composite enzyme preparation;

[0024] (3) Weigh 70 parts of pig manure, 10 parts of bran, 15 parts of rotten apple pomace and 5 parts of iron powder, fully mix, and prepare fermentation substrate;

[0025] (4) adding water to adjust the moisture content of the fermentation substrate to 60%;

[0026] (5) adding a compound enzyme preparation to the fermentation substrate with a water content of 60%, and the addition amount is 30 mg / g;

[0027] (6) Adjusting the pH of the fermentation substrate to pH=6.8, raising the temperature to 45° C., and incubating for 6 hours;

[0028] (7) Inoculate the composite ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com