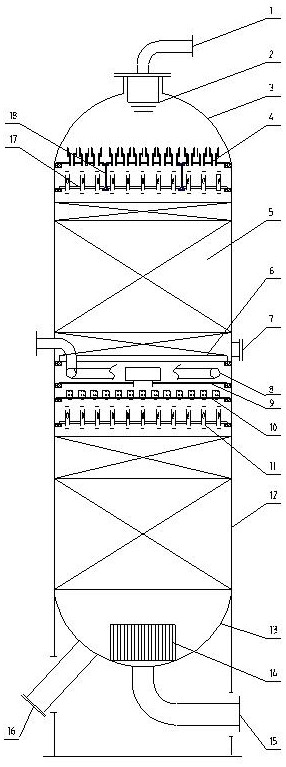

Hydrogenation reactor with flush plate on the top

A hydrogenation reactor and reactor technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of reducing the service life of the catalyst, damaging the performance of the catalyst, and varying the degree of reaction, so as to improve the distribution of materials, optimize the Effect of material distribution, uniform inlet conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

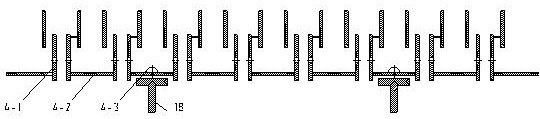

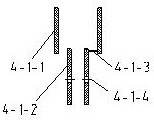

Embodiment 1

[0073] Compared with Example 1, in the upper head of the hydrogenation reactor, the bubble-cap type gas-liquid distributor is replaced by the folded-type spray plate of the present invention, and the folded-type injection plate of the present invention is used to replace the gas-liquid distributor. Flat tower sieve plate hole structure. The main parameters of the sleeve-type shock-reducing flow distribution plate are: the height of the shock-reducing barrel is preferably 300mm; the diameter of the shock-reducing barrel is preferably 150mm; 10%. The horizontal gap between the impact reduction cylinder and the chimney distributor is preferably 30mm; the cross-sectional area of the impact reduction cylinder is 5 times the cross-sectional area of the chimney distributor; the bottom edge of the impact reduction cylinder overlaps with the chimney distributor; the overlapping position is the height of the chimney distributor 20% of the chimney distributor; the height of the chim...

Embodiment 2

[0077] Compared with Example 1, the folded-edge type shock-reducing equalizer plate of the present invention is arranged above the bubble-cap type gas-liquid distributor in the upper head of the hydrogenation reactor, and the flat plate is replaced by the folded-edge spray plate of the present invention. Tower sieve tray hole structure. The main parameters of the sleeve-type shock-reducing flow distribution plate are: the height of the shock-reducing barrel is preferably 300mm; the diameter of the shock-reducing barrel is preferably 150mm; 10%. The horizontal gap between the impact reduction cylinder and the chimney distributor is preferably 30mm; the cross-sectional area of the impact reduction cylinder is 5 times the cross-sectional area of the chimney distributor; the bottom edge of the impact reduction cylinder overlaps with the chimney distributor; the overlapping position is the height of the chimney distributor 20% of the chimney distributor; the height of the chim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com