Peeling and cutting machine for sugarcane

A technology of cutting machine and sugar cane, which is applied in the fields of vegetable or fruit peeling, metal processing, food science, etc., can solve the problem that the quality and safety and hygiene of peeling cannot be guaranteed, the labor-intensive sugarcane peeling, and manual manual peeling Waste and other problems, to achieve the effect of retaining the original structure, improving peeling efficiency, and improving peeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

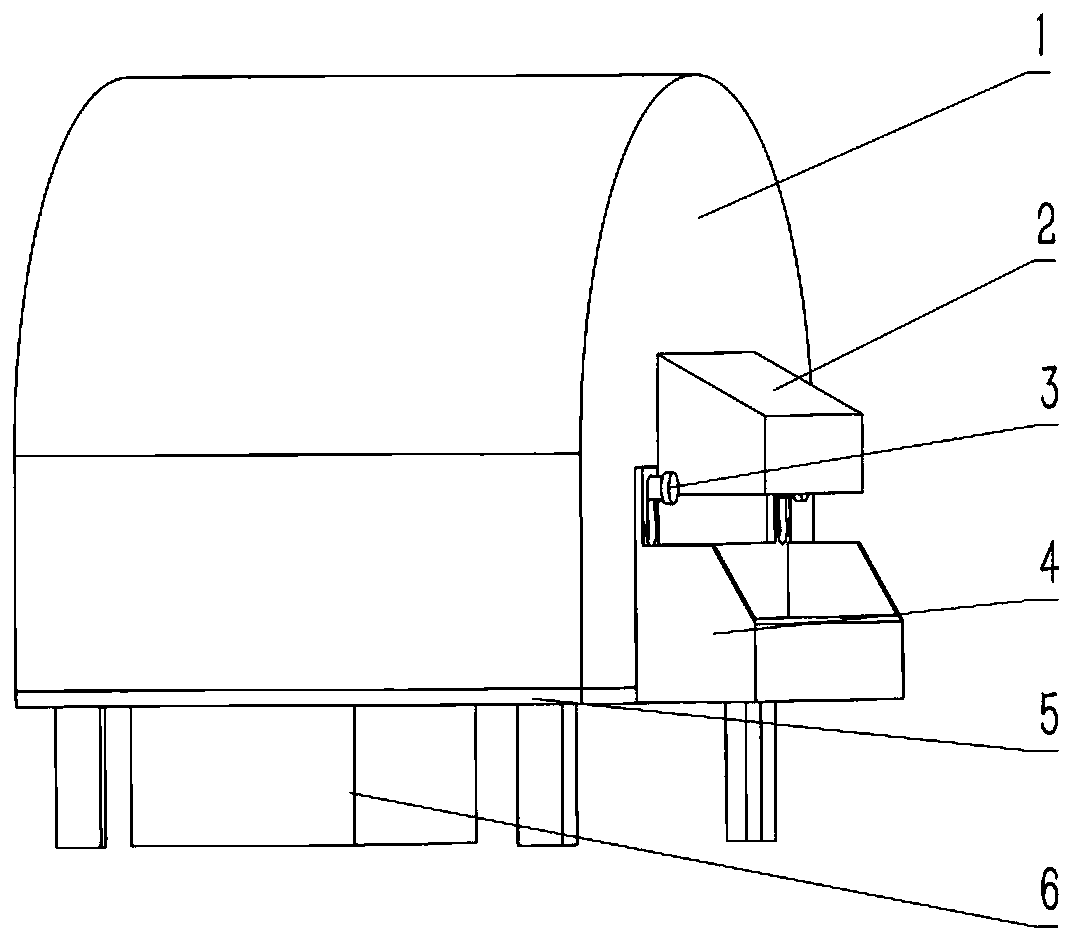

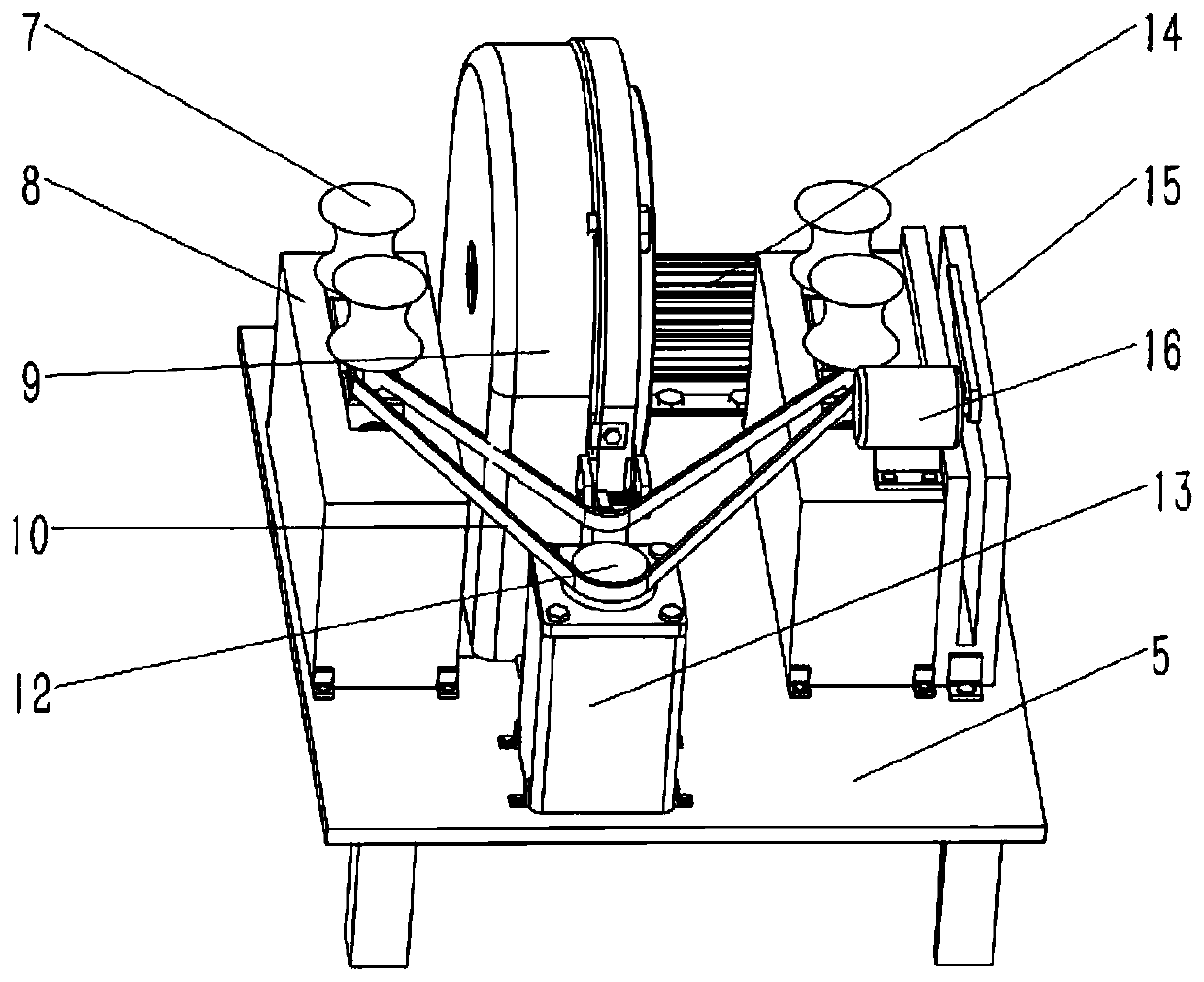

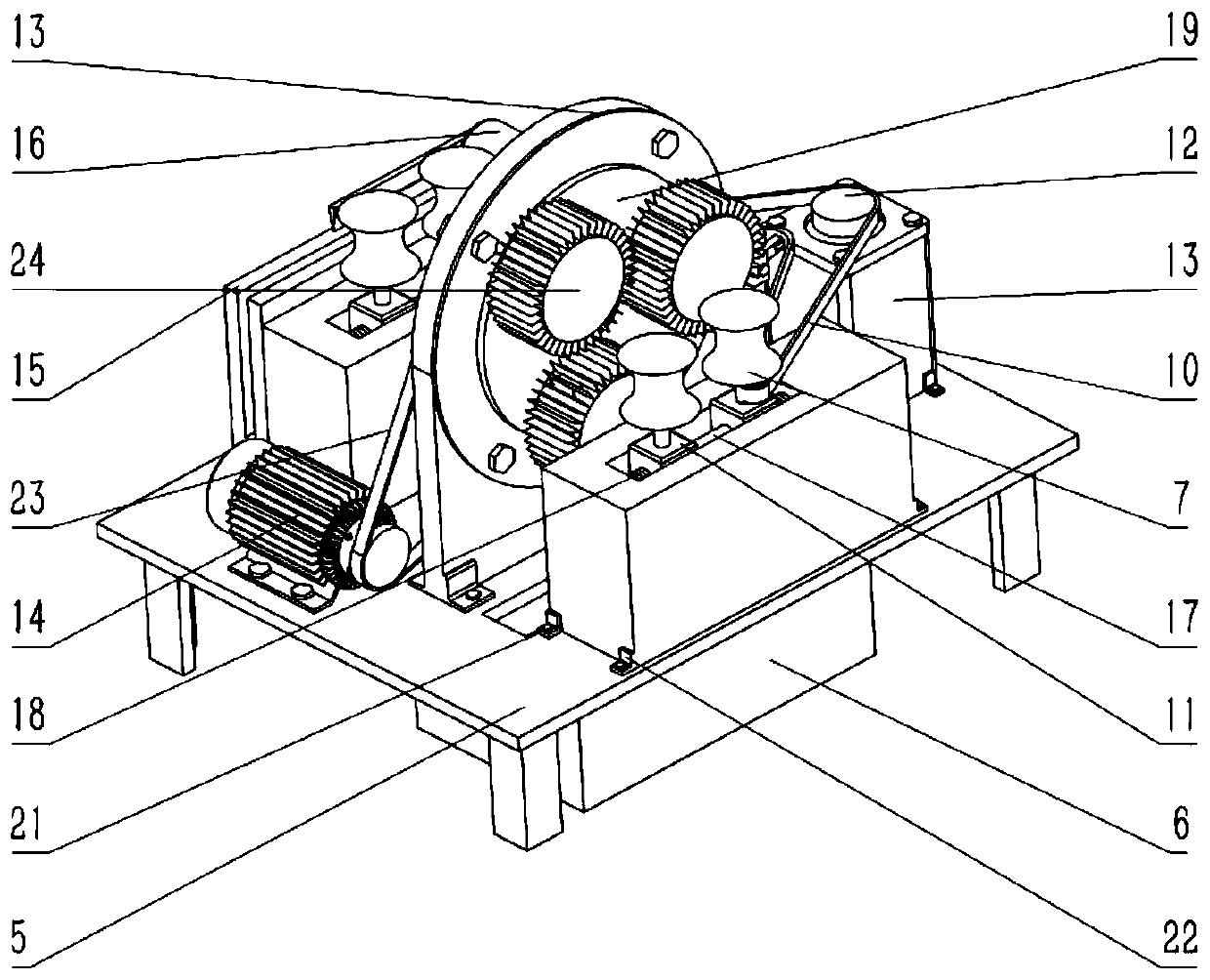

[0025] A kind of sugarcane peeling and cutting machine of the present invention, structure is as figure 2 , image 3 , Figure 4 As shown, it includes a ring gear fixing frame 43 vertically fixed on the base plate 5. The center of the ring gear fixing frame 43 is provided with a step hole, and the inner hole of the step hole is provided with a ring gear 39. The ring gear 39 is an internal gear structure. The ring gear fixing frame 43 and the ring gear fixing retaining ring 42 form a fastening structure and then fasten them. The ring gear fixing frame 43 and the ring gear fixing retaining ring 42 are fastened by bolts B33 and nuts 35. The ring gear 39 There is a peeling mechanism on the top, and a transmission disc 37 is provided on the outer hole of the step hole. The outer ring of the transmission disc 37 is connected with the motor B14 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com