Underground cable laying device

An underground cable, a pair of technology, applied in the direction of cable laying equipment, etc., can solve the problem that the automatic stop of the pay-off pulley cannot be realized, and the protection of the underground cable is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

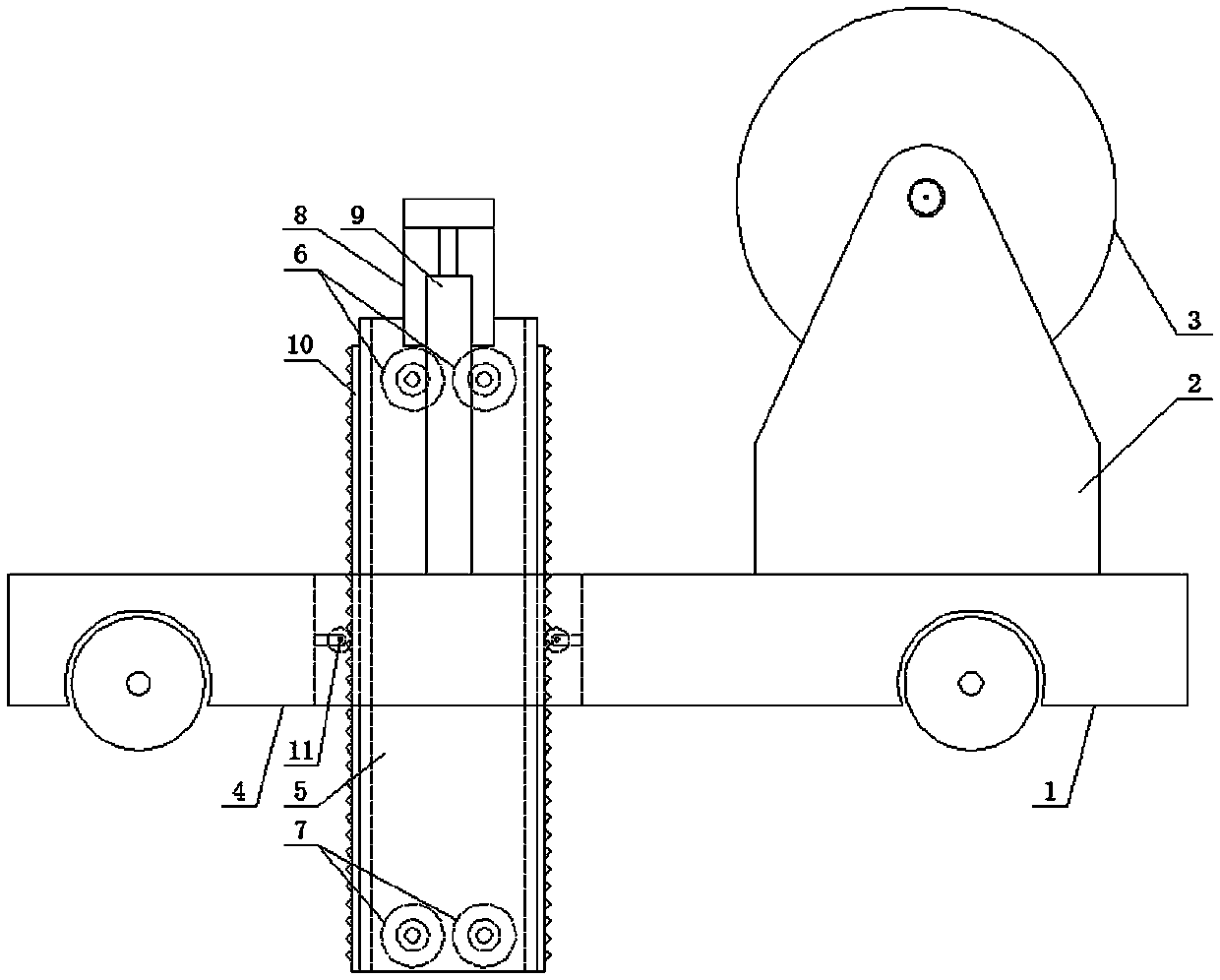

[0032] Such as figure 1 and figure 2 As shown, an underground cable laying device includes a trailer body 1, a pay-off frame 2 is arranged on the front side of the upper part of the trailer body 1, a cable reel 3 is rotatably arranged on the pay-off frame 2, and a cable reel 3 is arranged on the upper part of the trailer body 1. The rear side is provided with a guiding mechanism for guiding the wire into the cable shaft;

[0033] The guide mechanism includes a rectangular through hole 4 arranged on the rear side of the upper part of the trailer body 1, a rectangular cylinder 5 is arranged in a lifting manner in the rectangular through hole 4, and the inner side of the upper opening of the rectangular cylinder 5 is rotated. A pair of upper thread rolling wheels 6, a pair of lower thread rolling wheels 7 are rotated inside the lower opening of the rectangular cylinder 5, and a pair of inverted L-shaped push plates 8 are symmetrically arranged on the left and right sides of the...

Embodiment 2

[0037] Such as image 3 As shown, the difference between it and Embodiment 1 is that a tooth rack 10 is respectively arranged vertically on the four surfaces of the rectangular cylinder 5, and a corresponding rack 10 is arranged on the four inner walls of the rectangular via hole 4 respectively. A pinion 11 with a guide function that matches the rack 10.

[0038] In this embodiment, in order to prevent the rectangular cylinder from inclining when the device is used to lay cables in the underground cable shaft, a rack is arranged vertically on the four sides of the rectangular cylinder, and a rack is installed on the four sides of the rectangular via hole. A pinion gear with a certain guiding function is arranged on the four inner walls respectively and cooperates with the corresponding rack.

Embodiment 3

[0040] Such as Figure 4 Shown, its difference with embodiment 2 is:

[0041] The upper part of the trailer body 1 and the front and rear sides of the rectangular cylinder 5 are respectively provided with a locking mechanism for locking. The locking mechanism includes a slide rail 12 arranged on the upper part of the trailer body 1. A slide block 13 is slidably arranged on the slide rail 12, and the front end of the slide block 13 has a shape tooth 14 matched with the corresponding rack 10. A second automatic telescopic rod 16 is horizontally arranged on the inner surface of the inner surface, and the free end of the second automatic telescopic rod 16 is arranged on the slider 13 .

[0042] The second automatic telescopic rod 16 is an electric telescopic rod.

[0043] In this embodiment, in order to prevent the rectangular cylinder of the guiding mechanism from moving up and down when the device is used to lay cables in the underground cable shaft, one is provided on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com