Array radiation level-sensing device and measuring method thereof

A material level meter and array technology, applied in the field of material level meter, can solve the problems of small measurement range, long response time and poor directionality of passive nuclear material level meter, so as to solve the problem of inaccurate measurement, strong performance expansion capability, The effect of reducing the intensity of radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

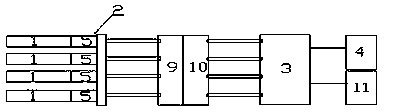

[0030] This embodiment provides an array radiation level gauge, such as figure 1 As shown, it mainly includes four scintillation crystals 1 and an array photoelectric conversion and multiplication unit 2 composed of four micro-devices 5 that can independently complete photoelectric conversion and multiplication, and also includes a filter 9, an amplifier 10, an operation processor 3 and Output unit 4; in the present embodiment, the arrayed photoelectric conversion and multiplication unit 2 preferably uses silicon photomultiplier tubes in an array layout, a microchannel plate photomultiplier tube, a microsphere photomultiplier tube or an avalanche diode in an array layout; Each scintillation crystal 1 is coupled with the array type photoelectric conversion and multiplication unit 2, the array type photoelectric conversion and multiplication unit 2 has four electrical signal channels, that is, a micro device 5 has an electrical signal channel; the input end of the filter 9 passes...

Embodiment approach 2

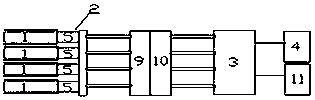

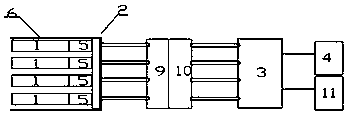

[0043] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, since there are cosmic background radiation noise signals around the scintillation crystal 1, these cosmic background radiation noise signals will lead to the final measured material level data Inaccurate, therefore, the array radiation level gauge in this embodiment also includes a radiation shielding component 6, and the radiation shielding component 6 is preferably a cover made of lead skin in practical applications. The radiation shielding component 6 is used to shield the cosmic background radiation noise signal around the scintillation crystal 1 in the non-measurement direction, so as to make the measurement result of the level gauge more accurate.

[0044] The radiation shielding part 6 can only cover the non-radiation receiving parts of the four scintillation crystals 1, such as figure 2 , or block the non-radiation-receiving parts of the four scintillation c...

Embodiment approach 3

[0047] This embodiment is a further improvement of Embodiment 2, such as Figure 5 , the array radiation level gauge in this embodiment further includes a noise shielding cover 7, and the noise shielding cover 7 completely covers and blocks any one of the four micro-devices 5. The main purpose of adding the noise shield 7 is: the arithmetic processor 3 can use the signal generated by the micro-device 5 covered by the noise shield 7 as the background noise signal, and the material level of the generated material in step S4 in the first embodiment In the process of data or image, the background noise signal can be used to correct the signals measured by other micro devices 5, so as to generate more accurate material level related data.

[0048] Apart from this, this embodiment is completely the same as Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com