Shield simulation testing device with adjustable angle

A simulation test and shield technology, applied to teaching models, instruments, mining equipment, etc., can solve problems such as repeated disassembly, achieve the effect of simple operation platform, improve test efficiency, and simplify disassembly and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

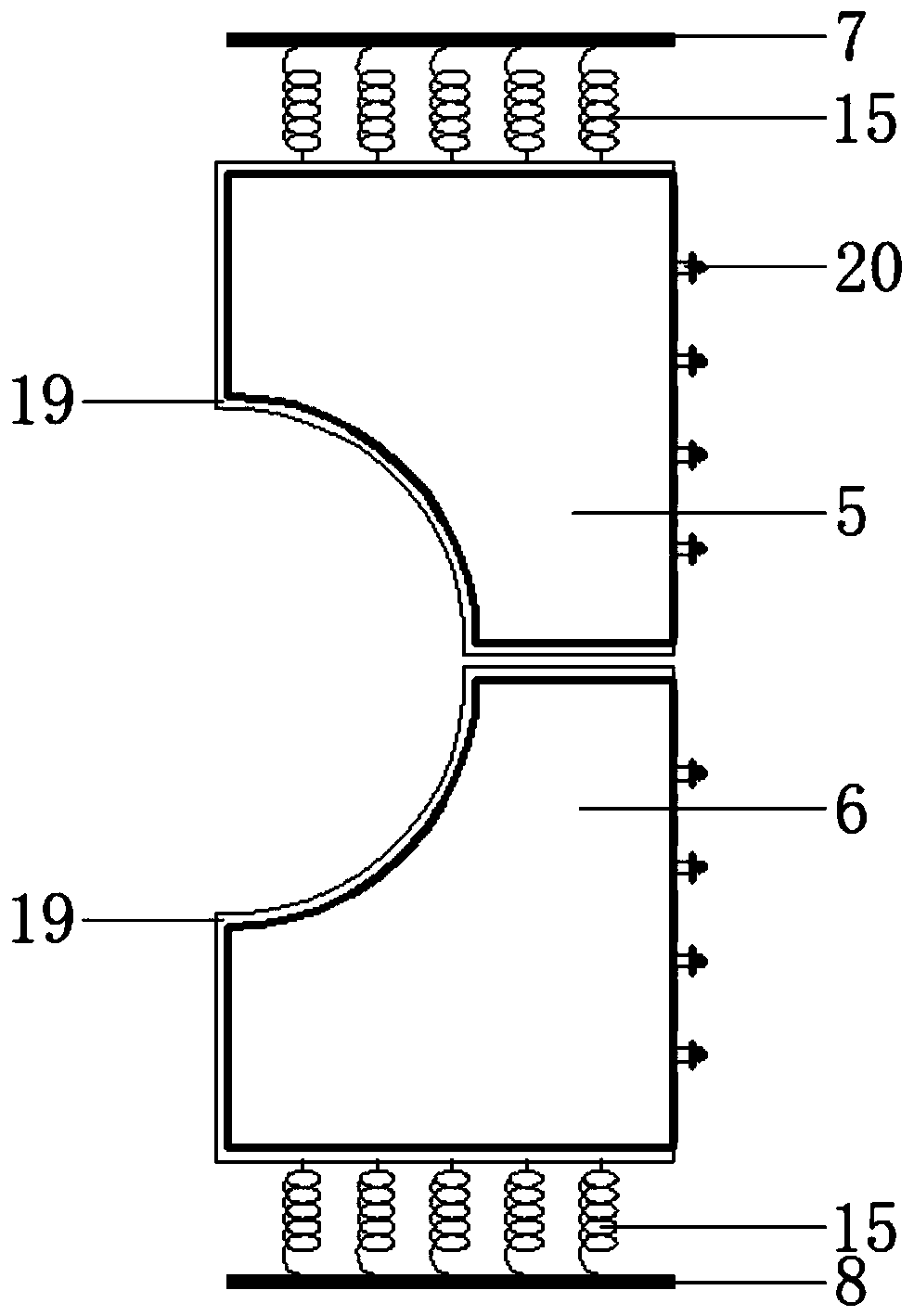

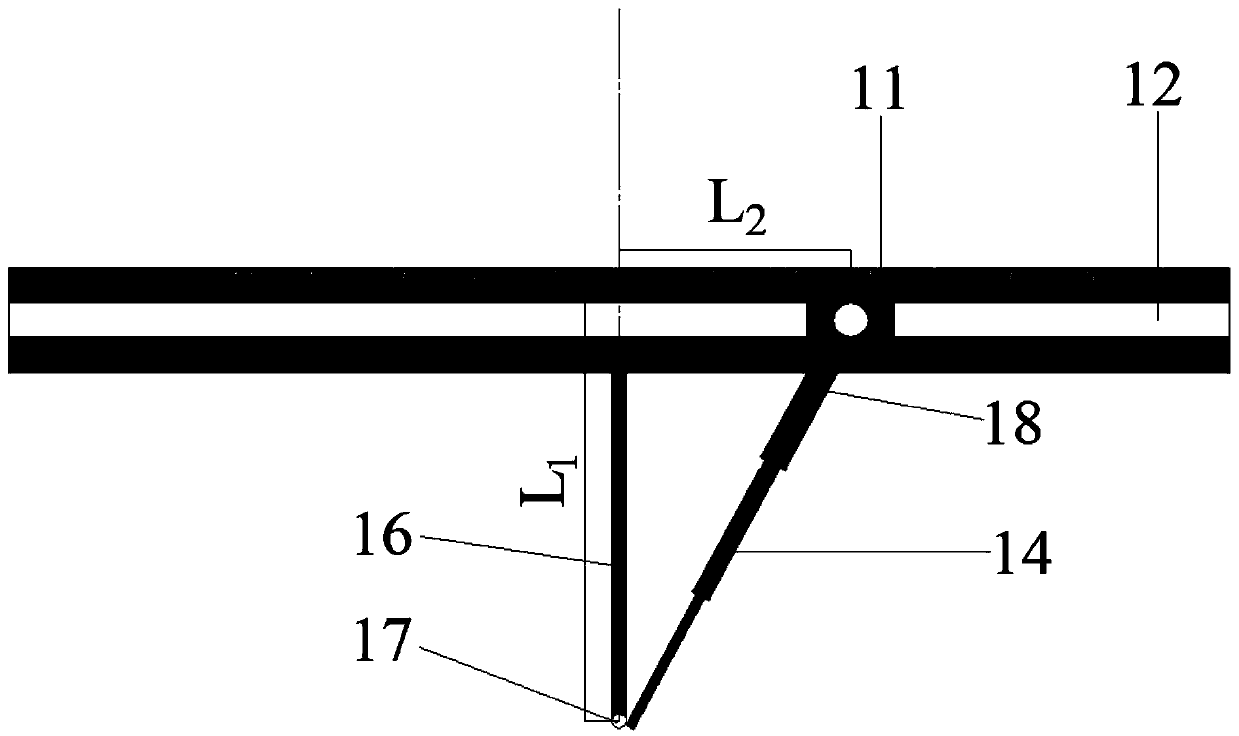

[0044] An angle-adjustable shield simulation test device, which includes a model box, a shield tunnel mold, a piston baffle, a first tunnel mold fixing plate, a second tunnel mold fixing plate, a telescopic rod, a slot, a fixing rod and Buckle; wherein, the first tunnel mold fixing plate and the second tunnel mold fixing plate are respectively arranged above and below one side of the model box, and the shield tunnel mold is fixed on the first tunnel mold fixing plate and the second tunnel mold fixing In the middle of the plate, 5mm thick water-stop rubber is set on the lower edge surfaces of the first tunnel mold fixing plate and the second tunnel mold fixing plate. On the one hand, it is used to fix the shield tunnel mold. The fine sand in the box leaked out, and part of the shield tunnel mold was embedded in the model box. The shape of the shield tunnel mold is a semi-cylindrical body used to simulate the completed tunnel for shield construction. The card slot is set on the ...

Embodiment 2

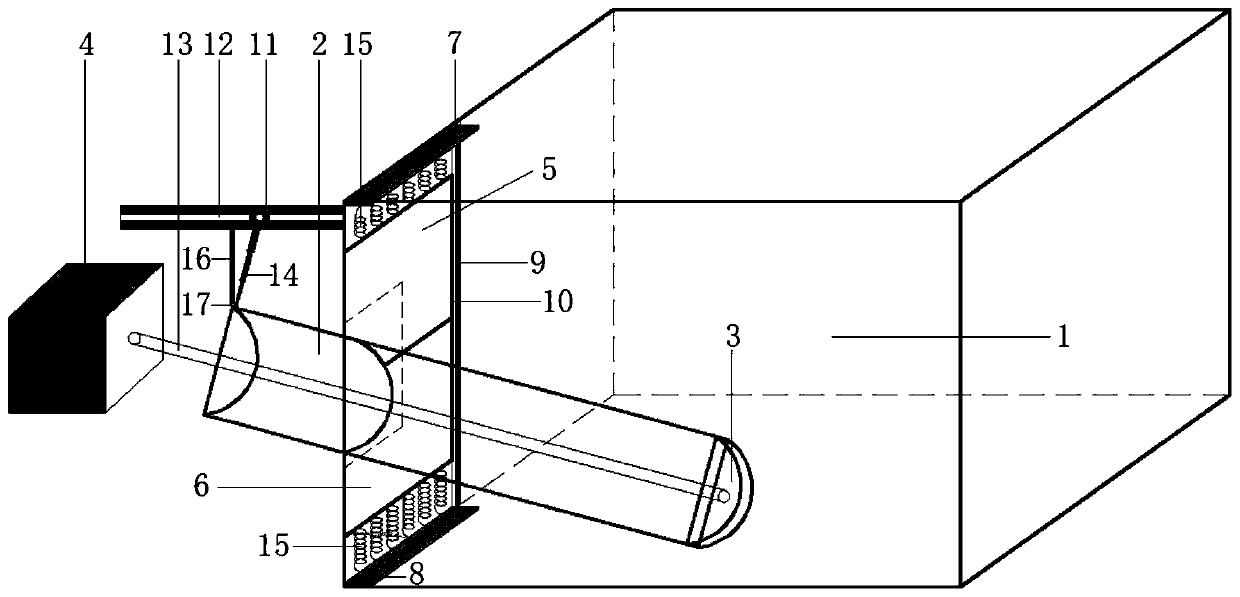

[0048] The shield simulation test device of the present embodiment is based on the embodiment 1, specifically as figure 1 As shown, it includes a model box 1, a shield tunnel mold 2, a piston baffle 3, a displacement controller 4, a first tunnel mold fixing plate 5, a second tunnel mold fixing plate 6, a buckle 11, a slot 12, Telescopic rod 14, fixed rod 16, spring 15 etc. The key components of the shield tunneling simulation experiment device are described in detail below:

[0049] Model box 1, its basic structure is a cubic box assembled by plexiglass plates around and at the bottom, and the top is exposed. The reserved size of the plexiglass plate on the side where the tunnel mold is installed is slightly larger than the hole of the shield tunnel mold;

[0050] Shield tunnel mold 2, its basic structure is a semi-cylindrical body made of Q235 steel, its cross-section is half a circle, placed close to the plexiglass, simulating the shield tunnel that has been built.

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com