Horizontal well crack plugging and wellbore reconstruction repeated-fracturing method

A technology for repeated fracturing and horizontal wells, which is applied in wellbore/well components, earthwork drilling and production, sealing/isolation, etc. It can solve problems such as inability to achieve large displacement reconstruction, increased risk of pipe sticking, poor cementing quality, etc. , to achieve the effects of flexible construction methods, improved construction timeliness, and wellbore cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

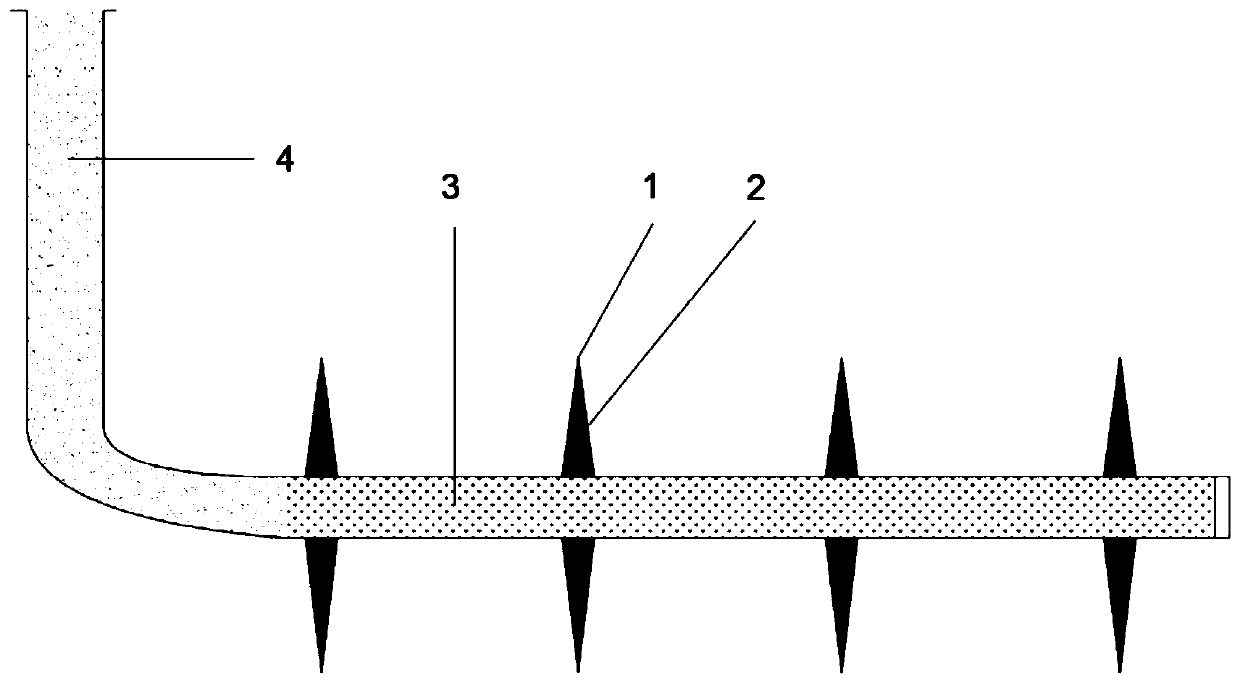

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] The present invention comprises the following steps:

[0037] 1. Wellbore reconstruction process:

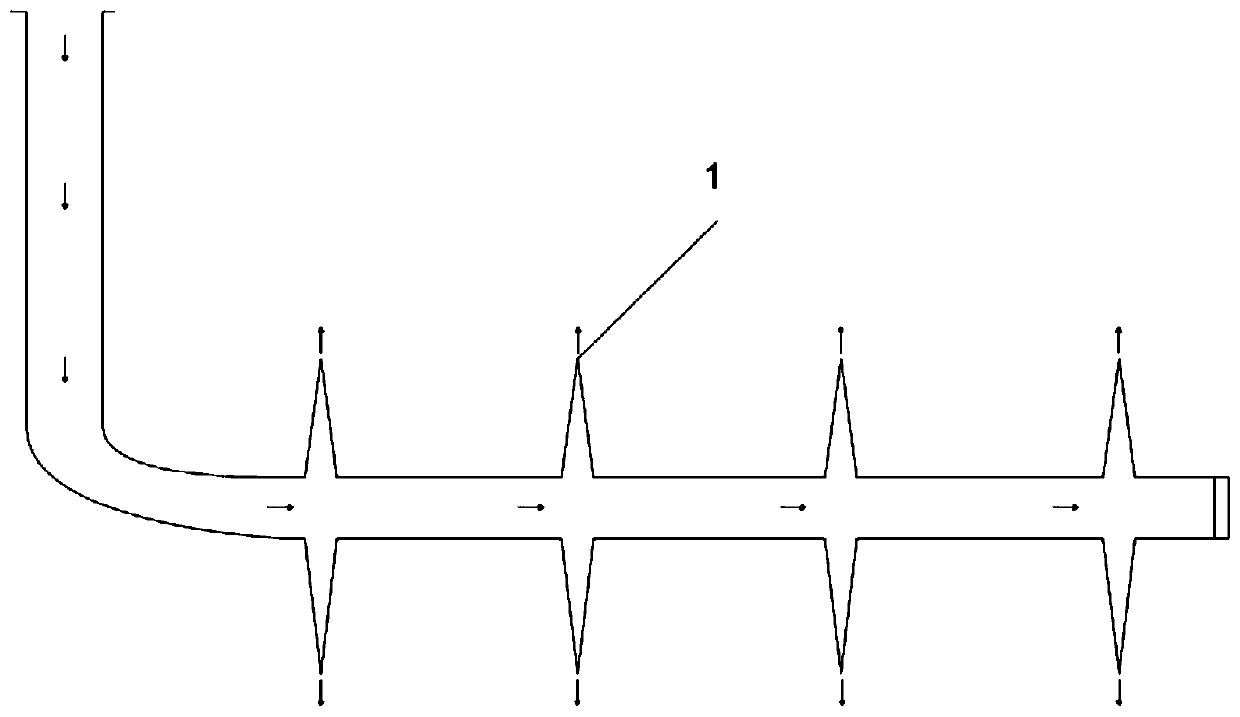

[0038] 1. Carry out wellbore energy replenishment. Due to the shortage of formation capacity caused by early mining, more than 3 times of liquid should be injected into the formation to restore its energy. The judgment standard is that the injection pressure at the wellhead is greater than the formation closure pressure of the well and the injection can be stopped (see figure 1 ), its role is to avoid subsequent material waste due to the large absorption of the formation, and save economic costs;

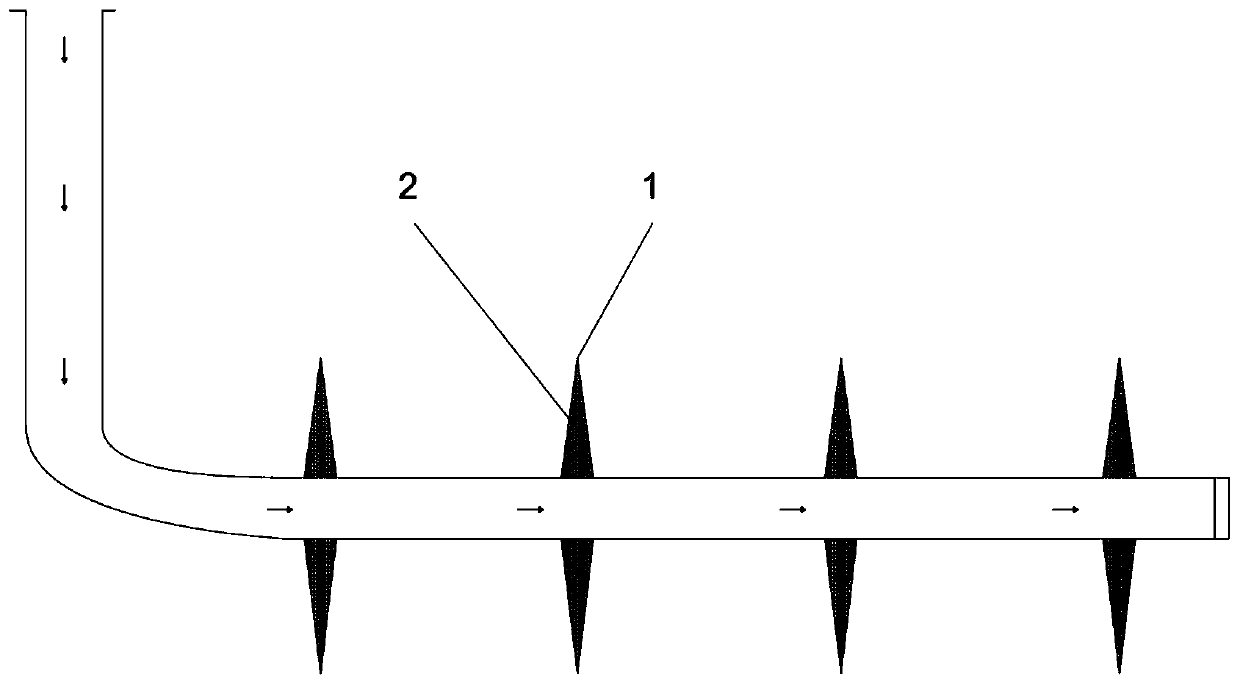

[0039] 2. Inject fracture plugging particles 2 into the original fracture 1 to seal the original fracture. The fracture plugging particles are low-density elastic particles. After entering the fracture, they are squeezed by formation pressure and rely on their own el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com