Dam bin surface green cutting device and construction method thereof

A technology for flushing and dams, which is applied in water conservancy projects, sea area engineering, infrastructure engineering, etc., can solve the problems of restricting the efficiency of flushing, high labor intensity, and affecting the quality of flushing, so as to reduce human resource investment and maximize safety Economic benefits, the effect of reducing manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

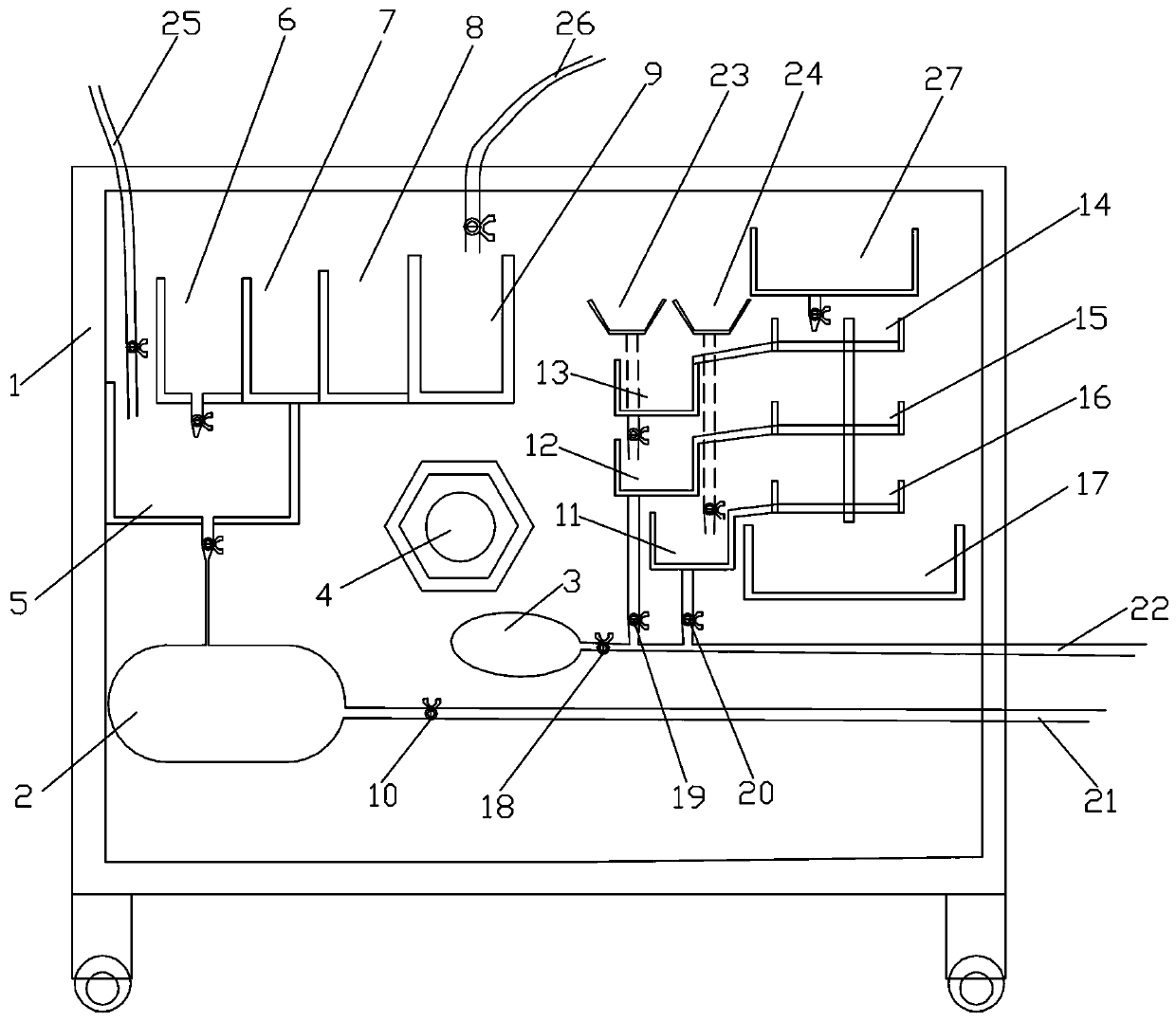

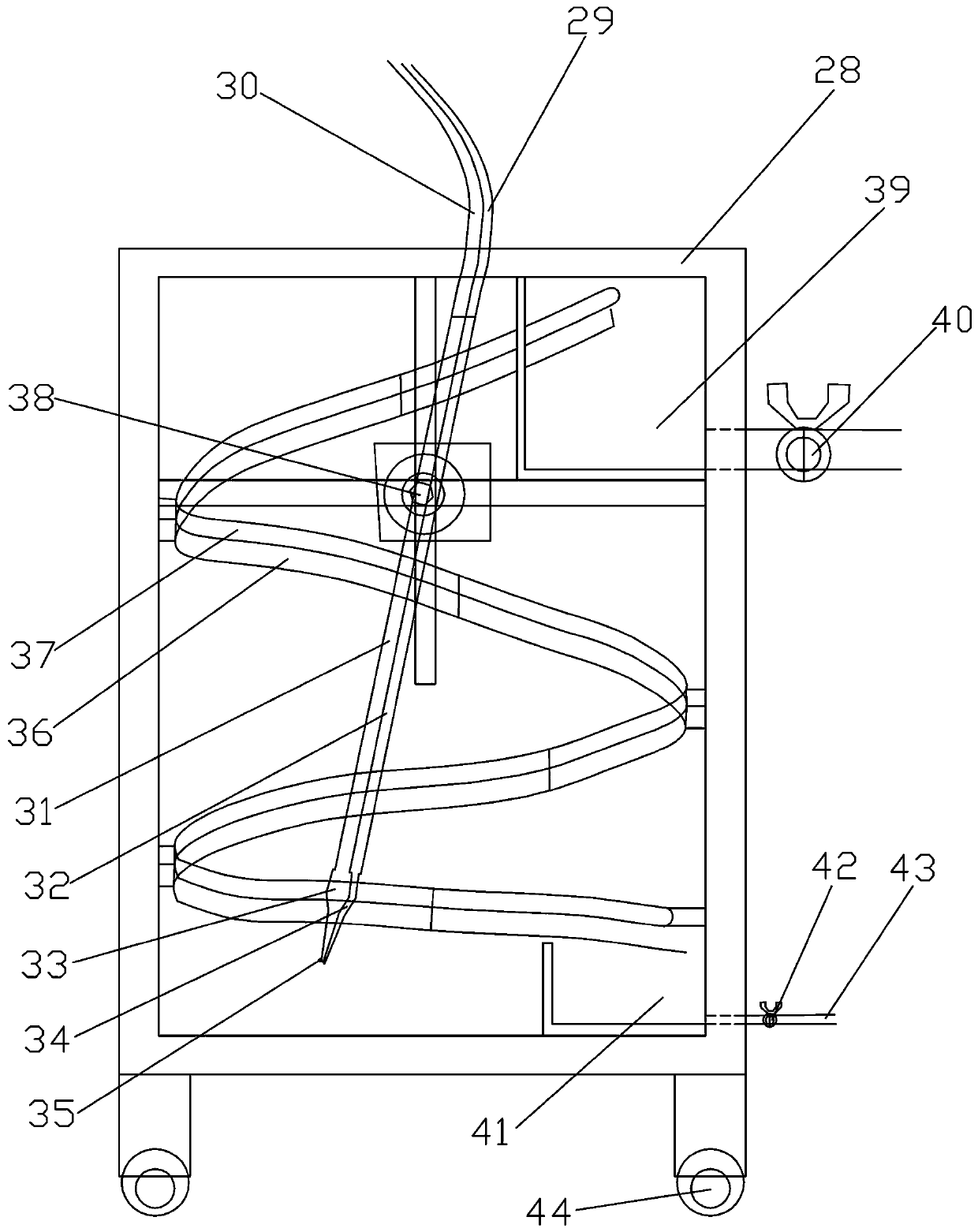

[0040] see Figure 1-4 , a kind of dam warehouse face flushing device, it comprises preparation device 1 and operating device 28, and described preparation device 1 comprises high-pressure water pump 2, air compression device 3 and central centralized control center 4, and the water inlet of described high-pressure water pump 2 Connected with the water storage tank 5, the water outlet of the high-pressure water pump 2 is connected with a high-pressure water outlet pipe 21, and the air outlet of the air compression device 3 is connected with a wind-sand outlet pipe 22, and the wind-sand outlet pipe 22 is simultaneously used for providing The sand box 11 of sand material is connected with the small stone box 12 for providing stone materials; the operating device 28 includes a high-pressure water gun 31 and an air sand gun 32 connected side by side, and the high pressure water gun 31 and the air sand gun 32 are provided with a water sand gun adjustment device 38, the high-pressur...

Embodiment 2

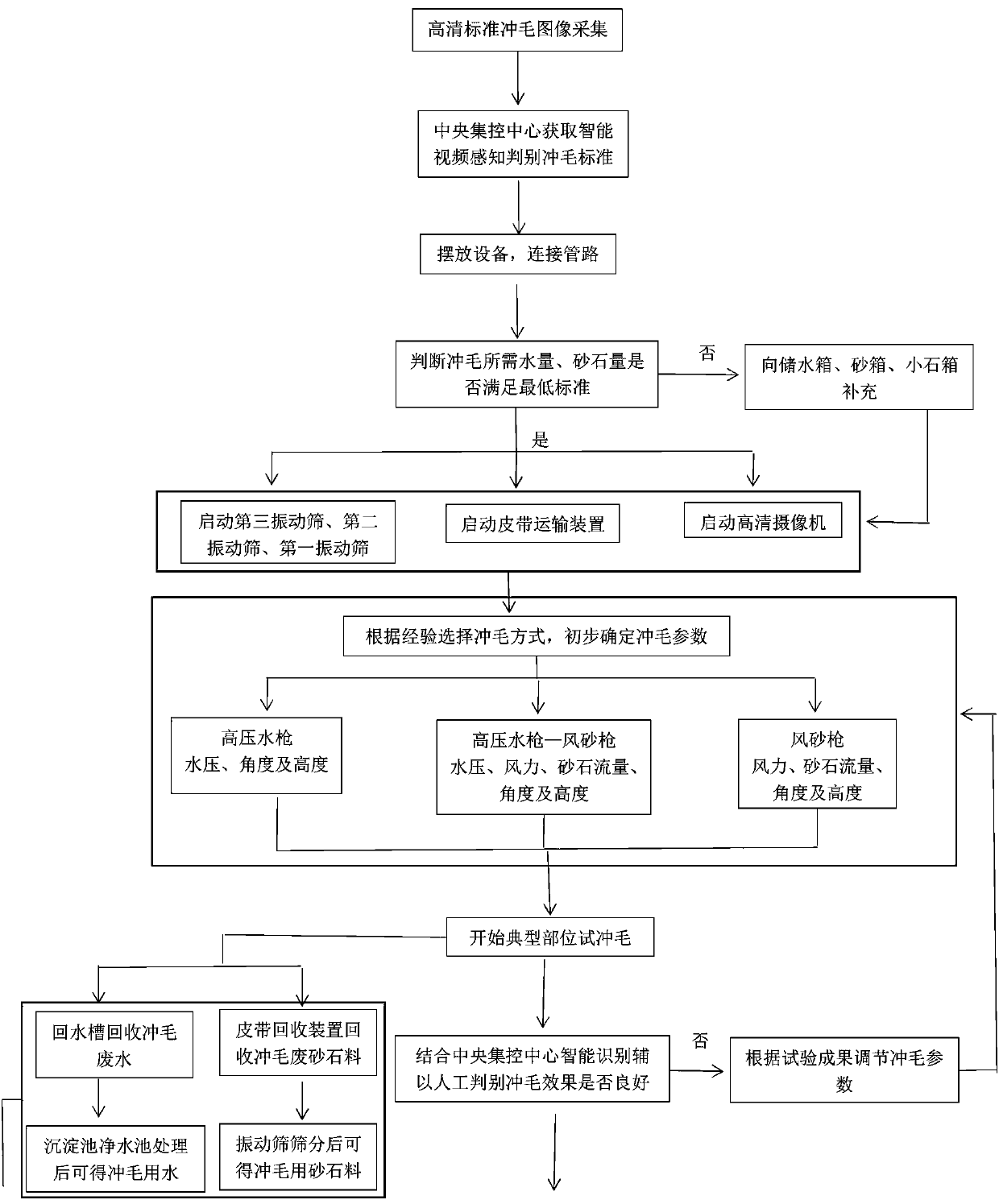

[0050] The construction method of the dam bin face flushing device comprises the following steps:

[0051] The first step is preliminary preparation. According to different flushing conditions, a large number of high-definition pictures of concrete surfaces that meet the quality of flushing are collected for intelligent algorithm video training to obtain high-definition standard pictures with the best flushing effect, and input to the central control center 4 for convenience. The miniature high-definition camera 35 continuously takes photos and compares and analyzes with the standard pictures when washing the hair, and judges in real time whether the washing effect meets the standard requirements;

[0052] In the second step, the operating device 28 is placed on the surface of the flushing chamber, the preparation device 1 is placed on the template or the adjacent chamber surface, and the first waste water outlet pipe 43 and the waste water inlet pipe 26, the high-pressure wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com