Wheel-type device for bridge floor press-anchoring of stay cable

A cable-stayed bridge deck and wheeled technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of limited cable-stayed control capability, large equipment scale, and high construction cost, and achieve convenient and standardized construction and equipment scale. The effect of small, less manpower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

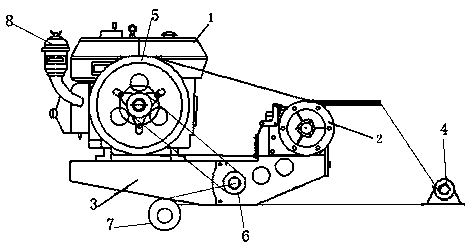

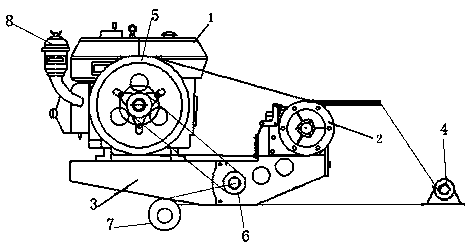

[0014] Such as figure 1 As shown, a wheeled device for anchoring on cable-stayed bridge decks includes an engine 1, a reaction wheel 2, a carrier frame 3, a hoist 4, a lifting wheel 5 and a drive shaft 6, an engine 1, and a reaction wheel 2 and the lifting wheel 5 are all installed on the carrier 3, the engine 1 is coaxial with the lifting wheel 5, the transmission shaft 6 is installed inside the carrier 3, the reaction wheel 2 is installed on one end of the carrier 3, and the engine 1 is installed on the end of the carrier 3 At the other end, the hoist 4 is installed on the bridge deck at the same level as the carrier frame 3 , the steel cable is connected to the hoist through the hoisting wheel 5 and the reaction wheel 2 , and the hoisting wheel 5 is connected to the transmission shaft 6 .

[0015] A ground wheel 7 is respectively installed on the left and right sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com