A cloth inspection machine

A cloth inspection machine and cloth inspection technology, which is applied in the field of cloth inspection machines, can solve the problems of creases and embossing of fabrics, difficult to roll up neatly, and poor inspection effect, so as to achieve convenient cloth inspection, fast air drying, and guarantee clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings.

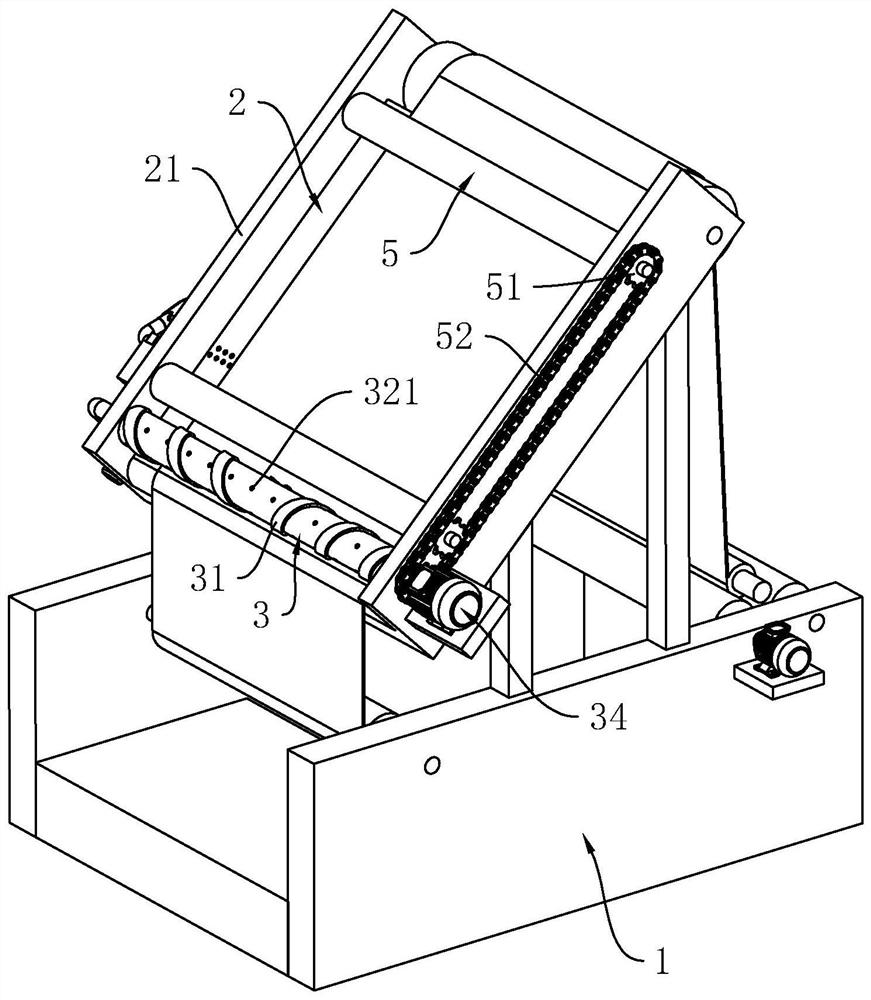

[0034] refer to figure 1 , which is a cloth inspection machine disclosed in the present invention, comprising a frame 1, and a cloth discharging assembly, a cloth inspection assembly 2 and a winding assembly are arranged on the frame 1 in sequence. The unwinding component is used to complete the unwinding of the cloth roll, the cloth inspection component 2 is used to complete the cloth inspection, and the rewinding component is used to rewind the cloth that has completed the cloth inspection.

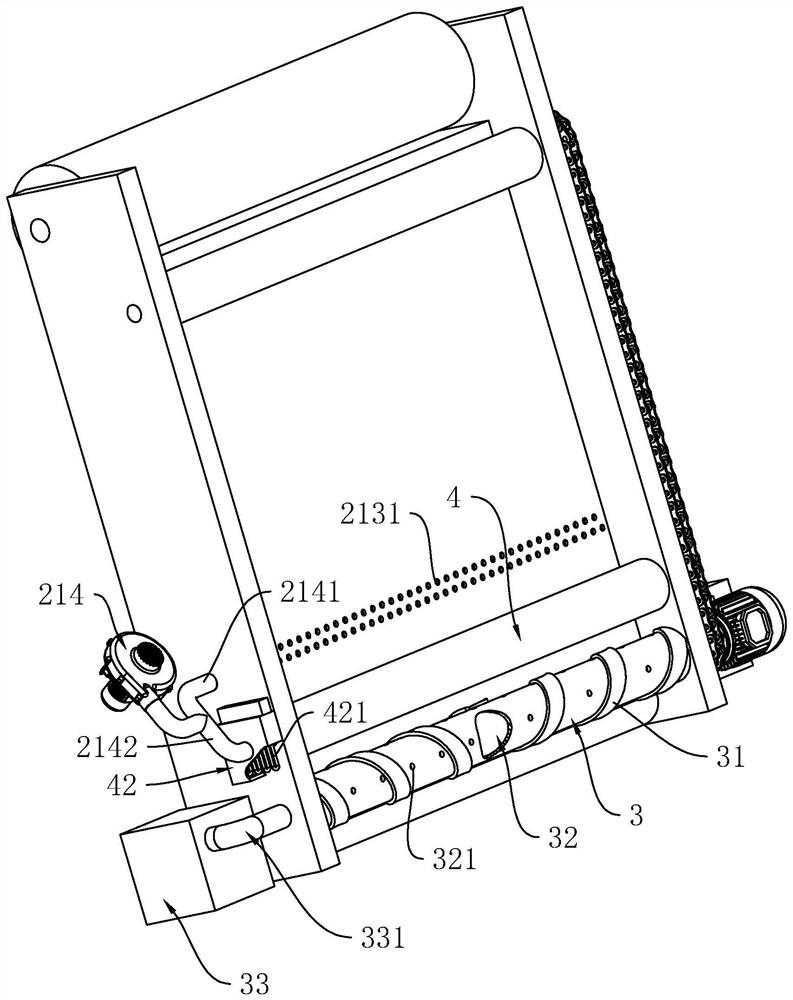

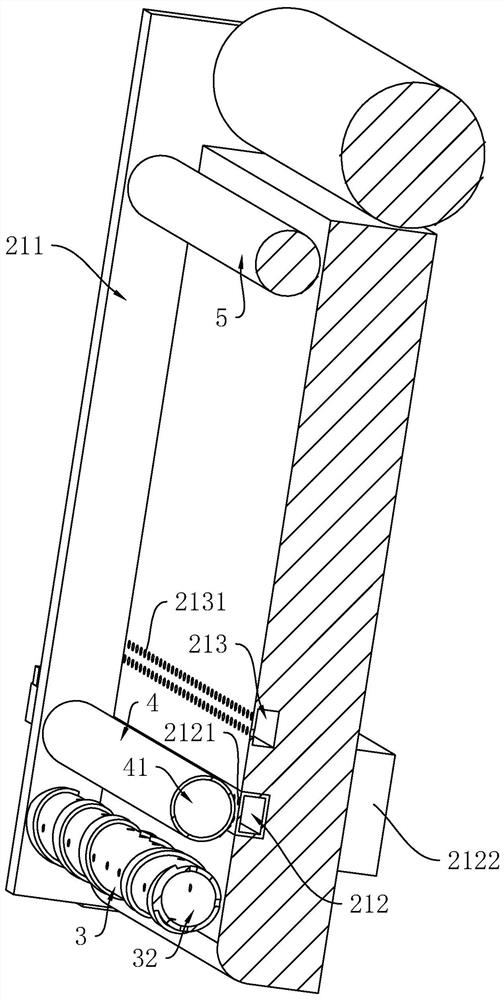

[0035] The cloth inspection platform 21 has a rectangular structure. Both ends of the cloth inspection platform 21 are fixed with vertical plates 211 perpendicular to the surface of the cloth inspection platform 21. The feeding end of the cloth inspection platform 21 is provided with a flattening roller 3. The flattening roller 3 The axial direction of the flattening ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com