Nano silver transparent amino acid handmade soap and preparation method thereof

An amino acid and nano-silver technology, applied in the field of daily necessities, can solve the problems of no sterilization, antibacterial and skin care, inconvenient storage, inconvenient modeling, etc., and achieve the effect of maintaining antibacterial performance, mild performance and good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

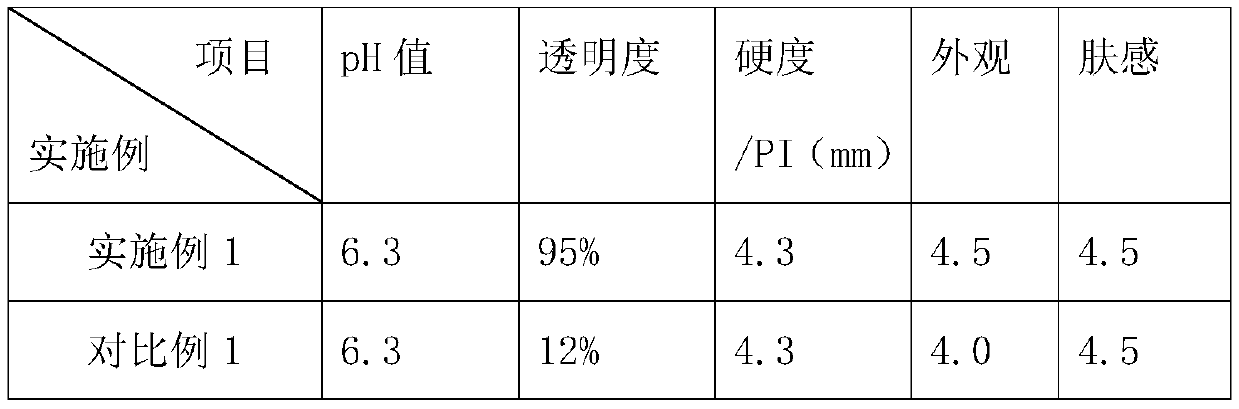

Embodiment 1

[0029] Raw material ratio: 30% lauroyl glutamic acid, 20% triethanolamine, 17% ethanol, 15.45% water, 10% glycerin, 5% sugar, 1% nano silver antibacterial stock solution, 0.5% sweet almond oil, vitamin E0.5 %, gold leaf 0.5%, essence 0.05%. Wherein the concentration of nano-silver in the antibacterial stock solution of nano-silver is 60ppm, and the average particle diameter of nano-silver is below 10nm.

[0030] preparation steps

[0031] A) Mix triethanolamine and ethanol according to the formula ratio, stir evenly, and control the temperature at 60°C to obtain a mixture, which is recorded as material A; B) Mix lauroyl glutamic acid, glycerin, white sugar and water according to the formula ratio, and control the temperature at 70°C , stirred to obtain a transparent mixed material, recorded as B material. C) Slowly add material A into material B, the stirring speed is controlled at 1000r / min, the temperature is controlled at 60°C, and the saponification time is 10min. D) Ra...

Embodiment 2

[0039] (1) Raw material ratio

[0040] Cocoyl glutamic acid 20%, arginine 10%, cystine 5%, triethanolamine 15%, sodium hydroxide 10%, ethanol 11.45%, water 18%, propylene glycol 3%, sugar 2%, nano silver 2% antibacterial stock solution, 0.5% olive oil, 1% vitamin E, 2% particle inclusions (bionic petals), 0.05% essence, wherein the concentration of nano-silver in the anti-bacterial stock solution of nano-silver is 60ppm, and the average particle size of nano-silver is below 10nm.

[0041] (2) Preparation steps

[0042] A) Mix triethanolamine, sodium hydroxide, and ethanol according to the formula ratio, stir evenly, and control the temperature at 60°C to obtain a mixture, which is recorded as material A; B) Mix cocoyl glutamic acid, arginine, and cysteine according to the formula ratio. Amino acid, propylene glycol, sugar and water, temperature controlled at 80°C, stirred to obtain a transparent mixture, which is recorded as material B. C) Slowly add material A into materi...

Embodiment 3

[0044] (1) Raw material ratio

[0045] Lauroyl glutamic acid 20%, cocoyl glutamic acid 10%, leucine 10%, triethanolamine 20%, potassium hydroxide 5%, ethanol 10.95%, water 15%, 1,3 butanediol 3% , lactose 1%, nano-silver antibacterial stock solution 3%, jojoba oil 0.5%, sweet almond oil 0.5%, particle inclusions (silk series) 1%, essence 0.05%, wherein the concentration of nano-silver in the nano-silver antibacterial stock solution is 300ppm, The average particle size of nano silver is below 10nm.

[0046] (2) Preparation steps

[0047]A) Mix triethanolamine, potassium hydroxide, and ethanol according to the formula ratio, stir evenly, and control the temperature at 80°C to obtain a mixture, which is recorded as material A; B) Mix lauroyl glutamic acid and cocoyl glutamic acid according to the formula ratio . C) Slowly add material A into material B, the stirring speed is controlled at 300r / min, the temperature is controlled at 80°C, and the saponification time is 25min. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com