Rare earth ion-doped bismuth oxyhalide up-conversion luminescent material and preparation method thereof

A technology of bismuth oxyhalide and rare earth ions, applied in the field of rare earth ion doped bismuth oxyhalide up-conversion luminescent materials and its preparation, can solve the problems of low luminous efficiency and low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

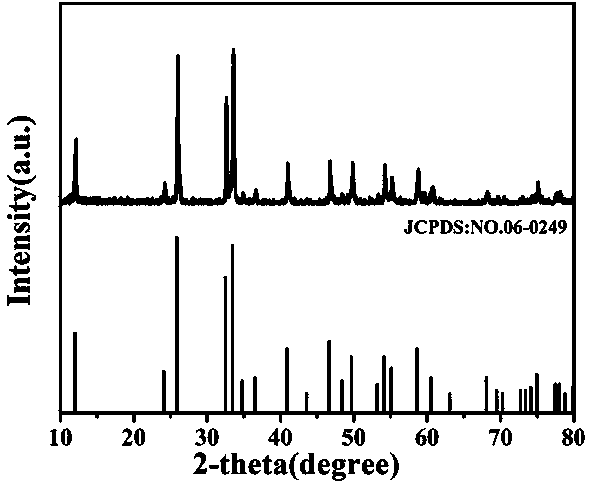

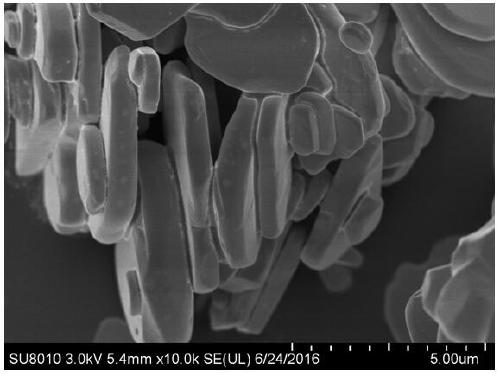

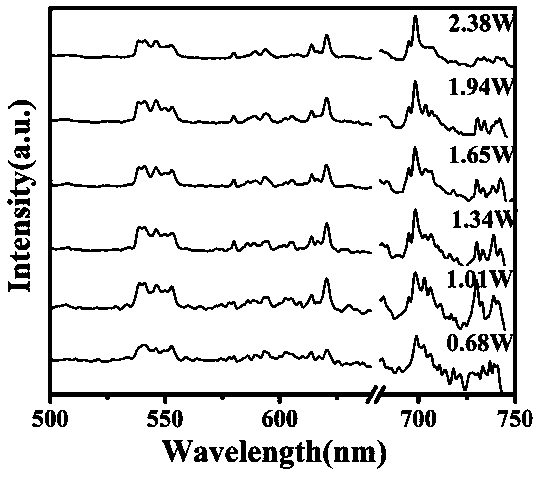

[0023] A rare earth ion doped bismuth oxyhalide layered semiconductor Bi 0.84 Eu 0.01 Yb 0.15 The preparation method of OCl up-conversion luminescent material, concrete steps are as follows:

[0024] A preparation method of Eu ion-doped bismuth oxyhalide semiconductor optical anti-counterfeiting material, the specific steps are as follows: Bi is weighed according to the molar ratio of Bi ions, Eu ions, Yb ions and Cl ions in a ratio of 0.84:0.01:0.15:1.2 2 o 3 、Eu 2 o 3 , Yb 2 o 3 , NH 4 Cl four kinds of raw materials (20% of the excess chlorine source is to prevent the lack of chlorine source in the reaction process), the Bi 2 o 3 、Eu 2 o 3 , Yb 2 o 3 , NH 4 Add grinding aids to the agate mortar, mix and grind evenly, place the ground reactants in a crucible, cover the surface of the crucible and sinter at a temperature of 500 °C for 3 hours, cool to room temperature, and sinter the sintered sample Grinding again in a ceramic mortar, the chemical formula can be...

Embodiment 2

[0029] A rare earth ion doped bismuth oxyhalide layered semiconductor Bi 0.85 Eu 0.04 Yb 0..01 The preparation method of OF up-conversion luminescent material, concrete steps are as follows:

[0030] A preparation method of Eu ion-doped bismuth oxyhalide semiconductor optical anti-counterfeiting material, characterized in that, the specific steps are as follows: according to the molar ratio of Bi ion, Eu ion, Yb ion and F ion, the ratio is 0.85:0.04:0.01:1.1 Weigh Bi 2 o 3 、Eu 2 o 3 , Yb 2 o 3 , NH 4 F four kinds of raw materials (NH 4 The 10% excess of F is to prevent the lack of F source during the reaction), and the Bi 2 o 3 、Eu 2 o 3 , Yb 2 o 3 , NH 4 F Add grinding aids into the agate mortar and mix and grind evenly, place the ground reactants in a crucible, cover the surface of the crucible and sinter at a temperature of 400°C for 4 hours, cool to room temperature, and place in a ceramic mortar Grinding, you can get the chemical formula Bi 0.85 Eu 0.04...

Embodiment 3

[0032] A rare earth ion doped bismuth oxyhalide layered semiconductor Bi 0.79 Eu 0.01 Yb 0.20 The preparation method of OBr up-conversion luminescent material, concrete steps are as follows:

[0033] A preparation method of Eu ion-doped bismuth oxyhalide semiconductor optical anti-counterfeiting material, characterized in that, the specific steps are as follows: according to the molar ratio of Bi ion, Eu ion, Yb ion and Br ion is the ratio of 0.79:0.01:0.20:1.2 Weigh Bi 2 o 3 , Eu 2 o 3 , Yb 2 o 3 , NH 4 Br four kinds of raw materials (NH 4 The 20% excess of Br is to prevent the lack of Br source during the reaction) to Bi 2 o 3 , Eu 2 o 3 , Yb 2 o 3 , NH 4 F Add grinding aids to the agate mortar and mix evenly, place in the crucible, cover the surface of the crucible and sinter at 450°C for 1 hour, cool to room temperature, and grind again in the ceramic mortar to obtain The chemical formula is Bi 0.79 Eu 0.01 Yb 0.20 Rare earth ion doped bismuth oxyhalide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com