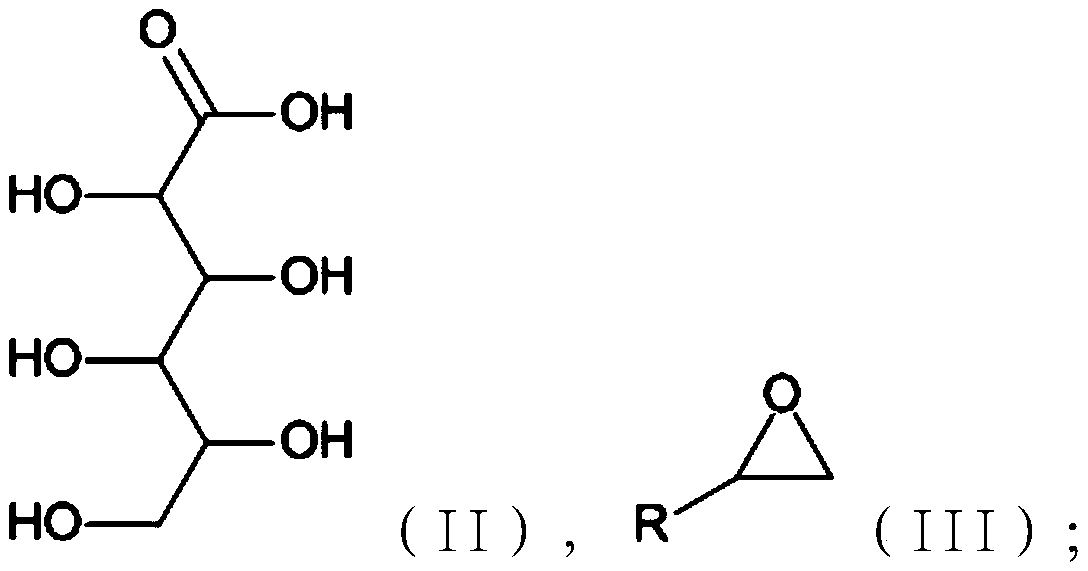

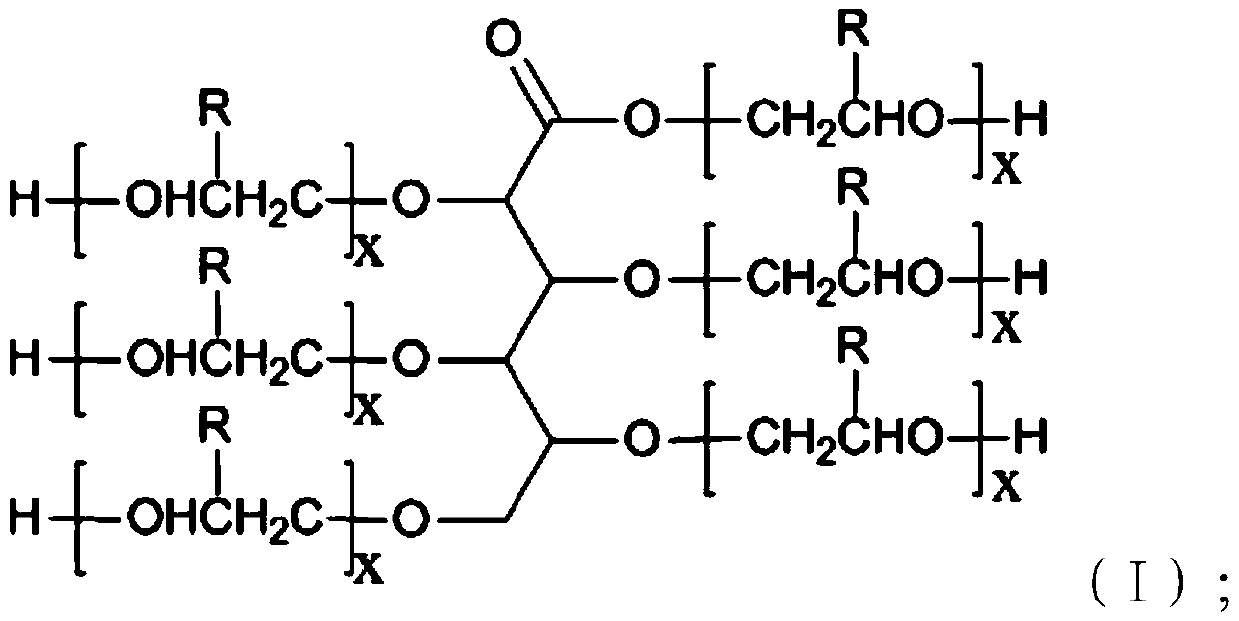

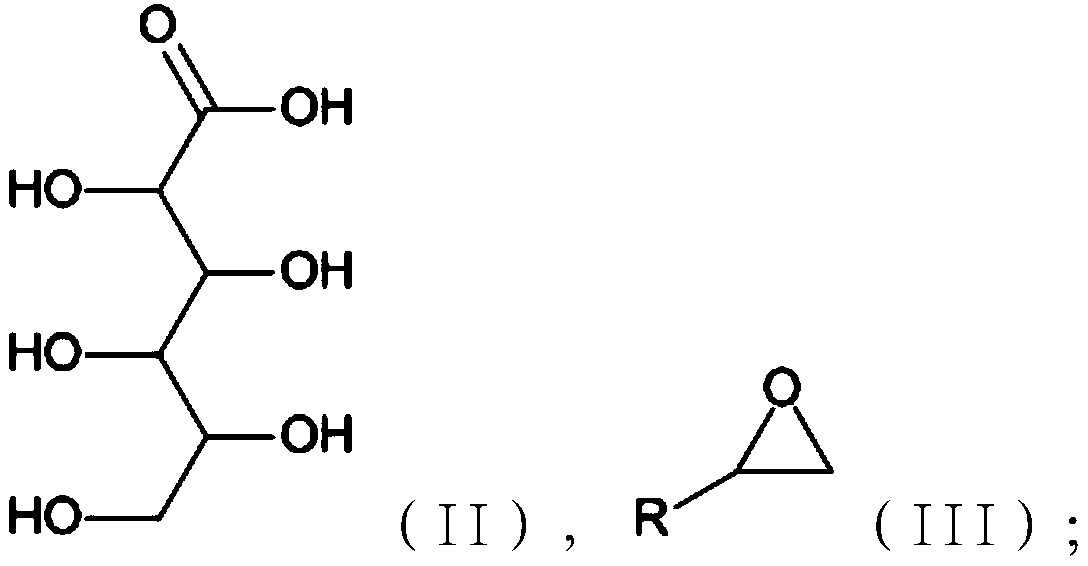

Gluconic acid initiated polyester ether polyol and application thereof in polyurethane hard foam

A polyester ether polyol, polyurethane rigid foam technology, applied in the field of new materials, can solve the problems of use limitation, poor mold release performance, low polyester functionality, etc., achieve strength improvement, reduce thermal conductivity value, intermolecular interaction force-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of preparation method of gluconic acid starting polyester ether polyol, the steps are:

[0057] 1) After mixing and dissolving 1176g of 50% mass concentration gluconic acid aqueous solution and 12g of potassium acetate, carry out nitrogen replacement, then heat to 80-90°C, then add 750g of propylene oxide at a flow rate of 750g / h, react for 1.5h, then Raise the temperature to 115°C, then carry out the aging reaction for 1h, and vacuum dehydrate at 110°C for 2h;

[0058] 2), according to the flow rate of 970g / h, add the remaining 970g of propylene oxide, continue to react at 95-105°C for 1h, then raise the temperature to 120°C for another 1h;

[0059] 3) At this time, add 100g water, 30g clay, absorb and decolorize, vacuum dehydrate and degas, filter to obtain gluconic acid starting polyester ether polyol E containing 200ppm potassium ions (existing in the form of potassium acetate), and the hydroxyl value is 460mgKOH / g, functionality is 5.5, viscosity is 35600m...

Embodiment 2

[0061] A kind of preparation method of gluconic acid starting polyester ether polyol, the steps are:

[0062] 1) After mixing and dissolving 840g of 70% mass concentration gluconic acid aqueous solution and 15g of potassium hydroxide, carry out nitrogen replacement, then heat to 90°C, then add 400g of ethylene oxide at a flow rate of 400g / h, react for 1.5h, and then heat up to 115 Then carry out aging reaction at 110°C for 1h, and vacuum dehydration at 110°C for 2h;

[0063] 2) Add the remaining 1480g of propylene oxide according to the flow rate of 800g / h, continue to react at 95-105°C for 1h, then raise the temperature to 120°C for another 1h;

[0064] 3) Add 24 grams of lactic acid and 100 g of water and stir for 0.5 h, then add 40 g of magnesium hexasilicate, absorb and remove potassium ions, vacuum dehydrate and degas, filter, and obtain gluconic acid starting polyester ether polyol F with a hydroxyl value of 410mgKOH / g, functionality 5.4, viscosity 27400mPa.s / 25℃.

Embodiment 3

[0066] A low-density and low-conductivity HFE-254 system polyurethane rigid foam, raw material composition:

[0067] The mass ratio of combined polyether to foaming agent and polyisocyanate is 100:18:140, specifically:

[0068] The composition of the combined polyether is as follows: 91.9 parts of polyether composition, 3 parts of surfactant, 3.1 parts of composite catalyst, and 2.0 parts of distilled water;

[0069] Foaming agent: 12 parts of CP (cyclopentane), 6 parts of HFE-254;

[0070] Polyisocyanate: polymerized MDI Wanhua PM-200 140 parts.

[0071] In combination polyether:

[0072] The polyether composition is composed of 51.9 parts by weight of gluconic acid starting polyester ether polyol E (prepared in Example 1): toluenediamine polyether polyol (OTDA is the starter, and the hydroxyl value is 350-450 mgKOH / g, Functionality 3.0-3.8, that is, polyether polyol B) 30 parts, glycerol polyether polyol (hydroxyl value 192mgKOH / g, functionality 2.3, namely polyether poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com