Refining method and refining system of p-xylene crude product

A technology for crude xylene and p-xylene, which is applied in chemical instruments and methods, isomerization hydrocarbon production, and hydrocarbon purification/separation, etc. rate, adverse effects of adsorbent adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] The refining method and refining system of the present invention will be further illustratively explained and described below using examples in conjunction with the accompanying drawings, but the present invention is not limited to these examples.

[0110] In the following examples and comparative examples, in order to facilitate the understanding of those skilled in the art, the p-xylene crude product manufacturing unit, conversion unit, separation unit II and pre-refining steps are sometimes quoted, but these are all for the present invention optional. Those skilled in the art may not use these, or replace them with any other units or steps known in the art that can perform similar functions or achieve similar purposes.

[0111] In the following examples and comparative examples, the starting feed stream may be from one or more sources containing C8+ aromatics, including C8+ reformate, toluene shape-selective disproportionation, alkylation products, or C8-containing a...

Embodiment 1

[0118] Embodiment 1 is basically the same as Comparative Example 1, except that unit 141 is newly added, and unit 140 and unit 141 are operated according to the requirements of the present invention.

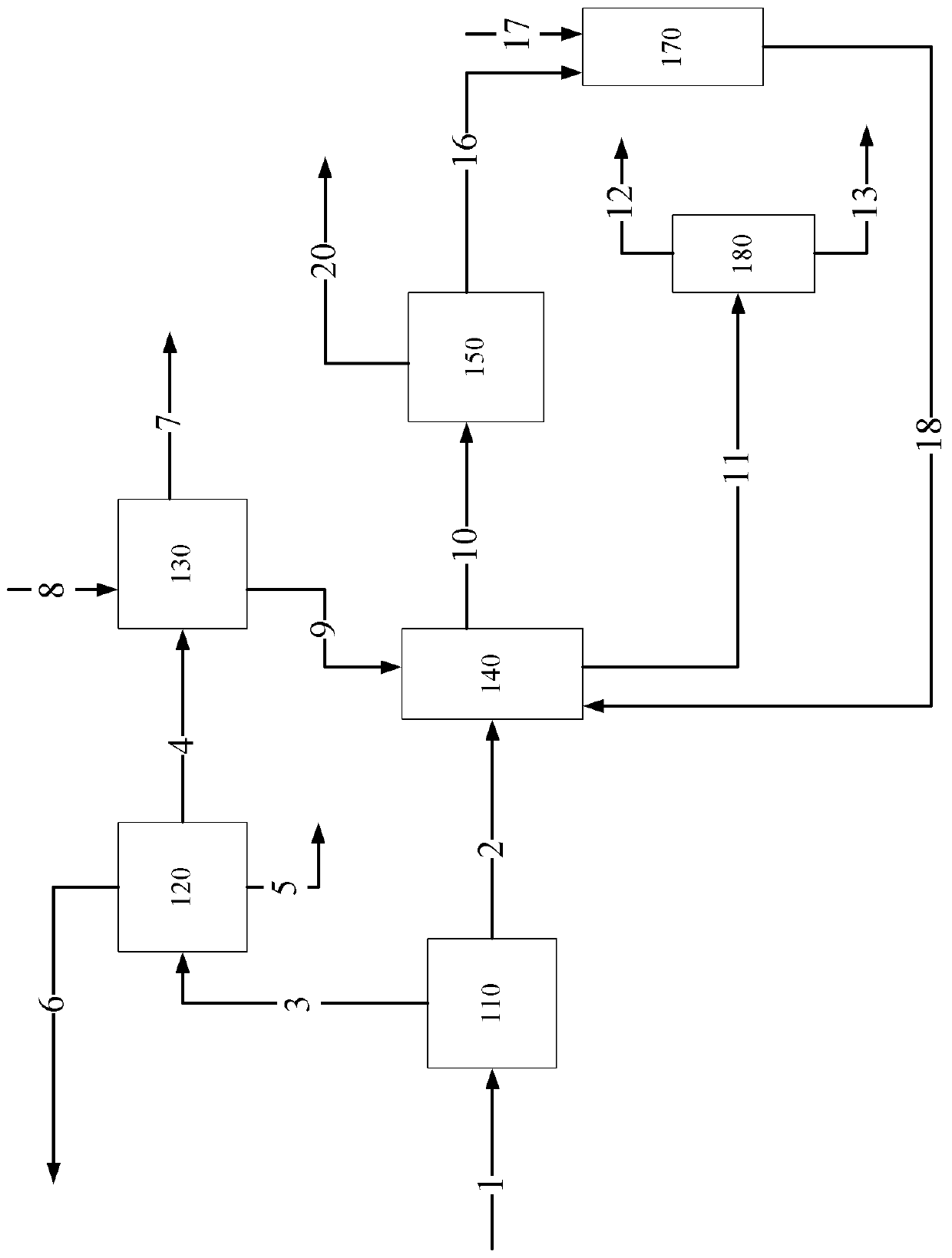

[0119] Such as figure 2 As shown, starting material stream 1 first enters fractionator 110 for light and heavy component cutting (i.e., pre-refining), containing C 6 -C 7 The material of the components enters the 120 extraction unit through the pipeline 2 as the extraction raw material, and the 120 extraction unit separates the extraction benzene (line 4), the intermediate material C7A (line 3) and the hydrogenated raffinate (line 5). The C8+-enriched component separated by the fractionation tower 110 is used as the raw material of the xylene unit (ie, a crude p-xylene product) and enters the unit 140 (ie, the separation unit I or the I-1 separation unit) through the line 10 . The pipeline 3 contains the extracted C7A stream, which is used as the reaction raw material of the ...

Embodiment 2

[0125] Embodiment 2 is basically the same as Comparative Example 1, except that unit 141 and unit 142 are newly added, and unit 140, unit 141 and unit 142 are operated according to the requirements of the present invention.

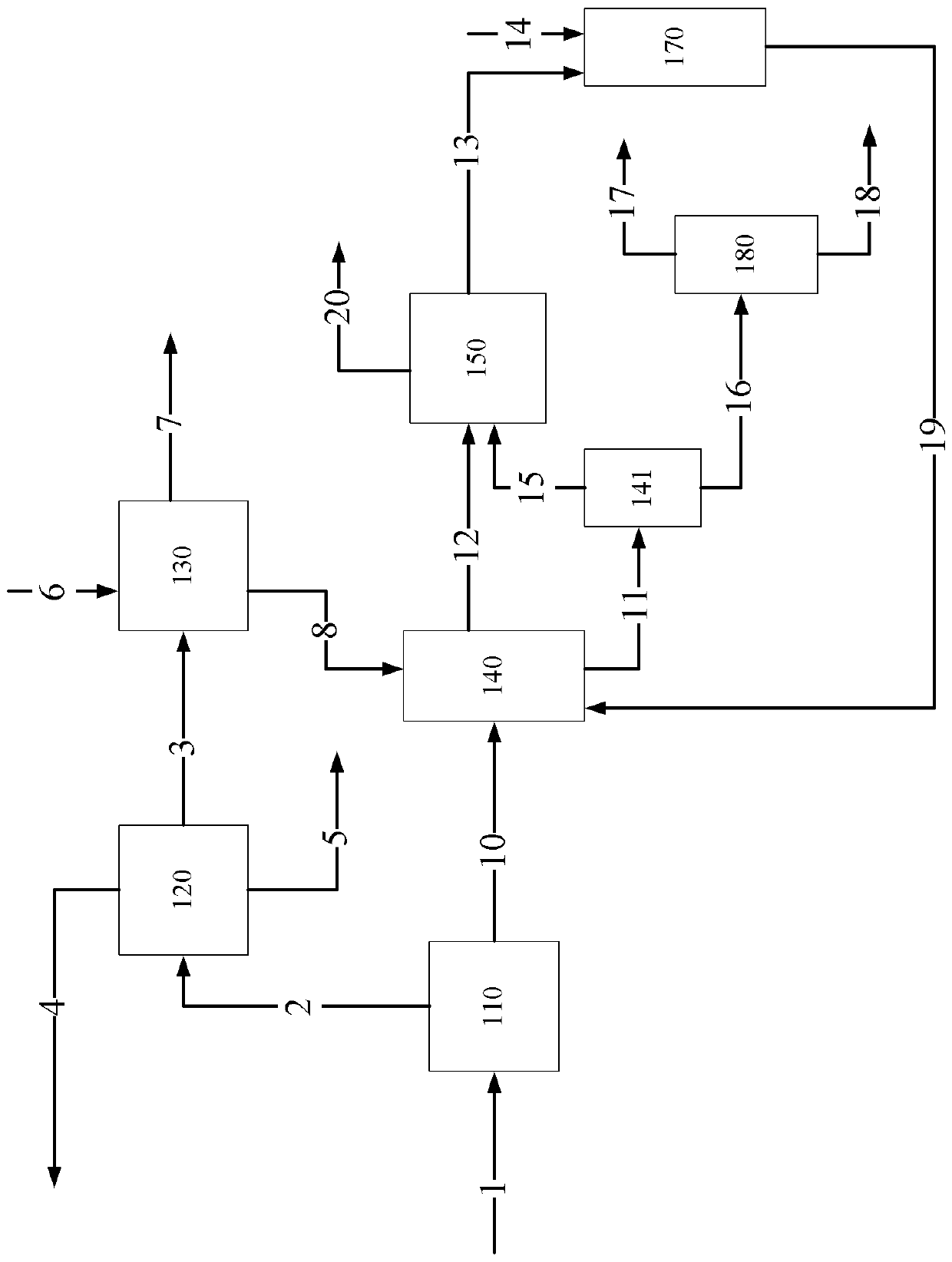

[0126] Such as image 3 As shown, starting material stream 21 first enters fractionator 110 for light and heavy component cutting (i.e., pre-refining), containing C 6 -C 7 The material of the components enters the 120 extraction unit through the pipeline 22 as the extraction raw material, and the extraction benzene (the pipeline 25), the intermediate material C7A (the pipeline 24) and the hydrogenated raffinate (the pipeline 26) are separated by the extraction unit; and The C8+-enriched component separated by the fractionation tower 110 is used as the raw material of the xylene unit (ie, a crude p-xylene product) and enters the 140 unit (ie, the separation unit I or the I-1 separation unit) for further processing. The C7A stream is extracted in the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com