A matte high antifouling glaze, ceramic tile and preparation method thereof

A matte and anti-fouling technology, applied in the field of ceramic tiles, can solve the problems of low surface gloss, rough surface texture, etc., and achieve the effect of easy removal and guaranteed firing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

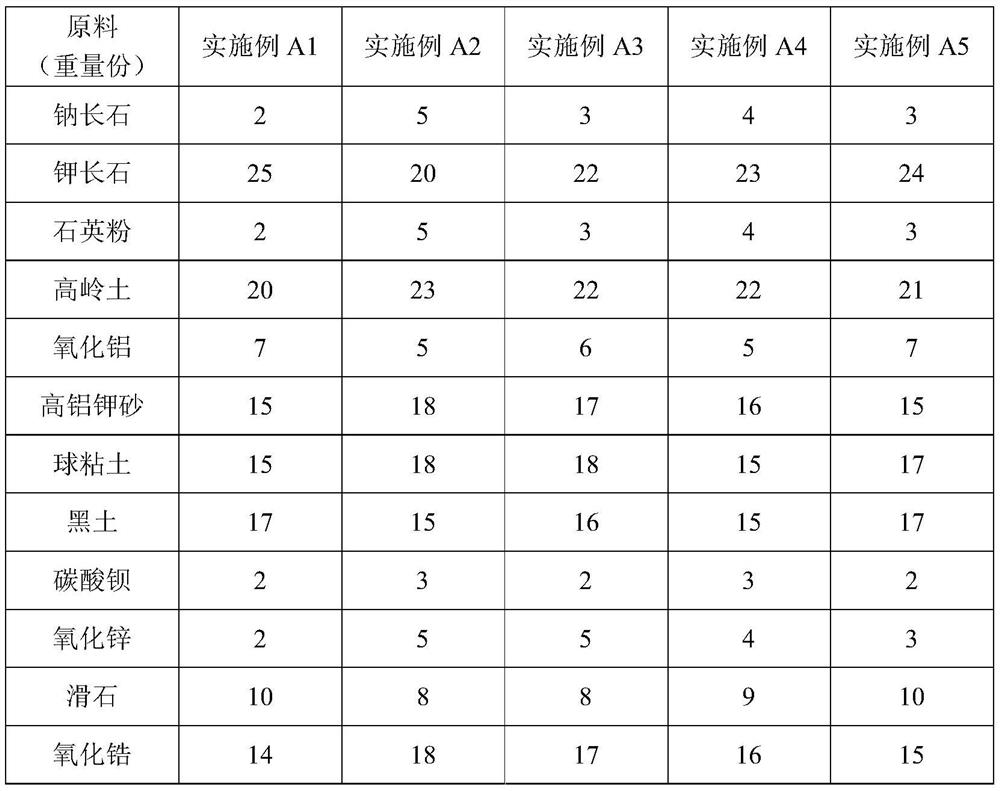

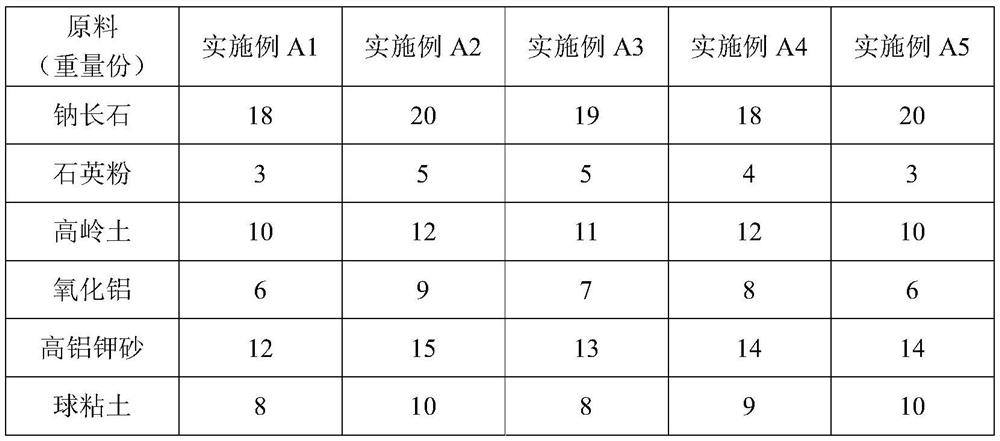

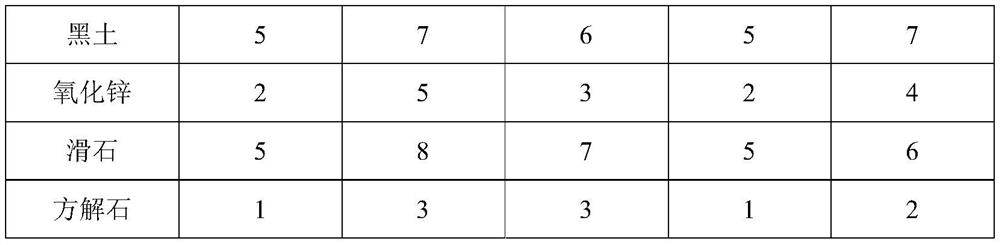

Examples

preparation example Construction

[0037] The preparation method of the above-mentioned matte high antifouling ceramic tile comprises the following steps:

[0038] (1), prepare adobe;

[0039] (2), prepare the glaze slurry of the bottom glaze: all the bottom glaze raw materials are added to the ball mill, and sodium hydroxymethyl cellulose, sodium tripolyphosphate and water are mixed into the ball mill, and the ball mill gets the bottom glaze slurry, and the particles in the slurry are 0.056~0.063mm;

[0040] (3), prepare the glaze slurry of the surface glaze: all the surface glaze raw materials are added to the ball mill, and sodium hydroxymethyl cellulose, sodium tripolyphosphate and water are mixed into the ball mill, and the ball mill is used to obtain the surface glaze slurry, and the particles in the slurry are 0.040~0.050mm;

[0041] (4), first apply the bottom glaze slurry on the surface of the brick, then apply the top glaze slurry on the brick with the bottom glaze slurry, and the top glaze slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com