Preparation method of alpha-silicon nitride powder

The technology of silicon nitride powder and powder is applied in the field of preparation of α-silicon nitride powder, which can solve problems such as affecting the formation of silicon nitride crystal grains, and achieve low production cost, high powder purity and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

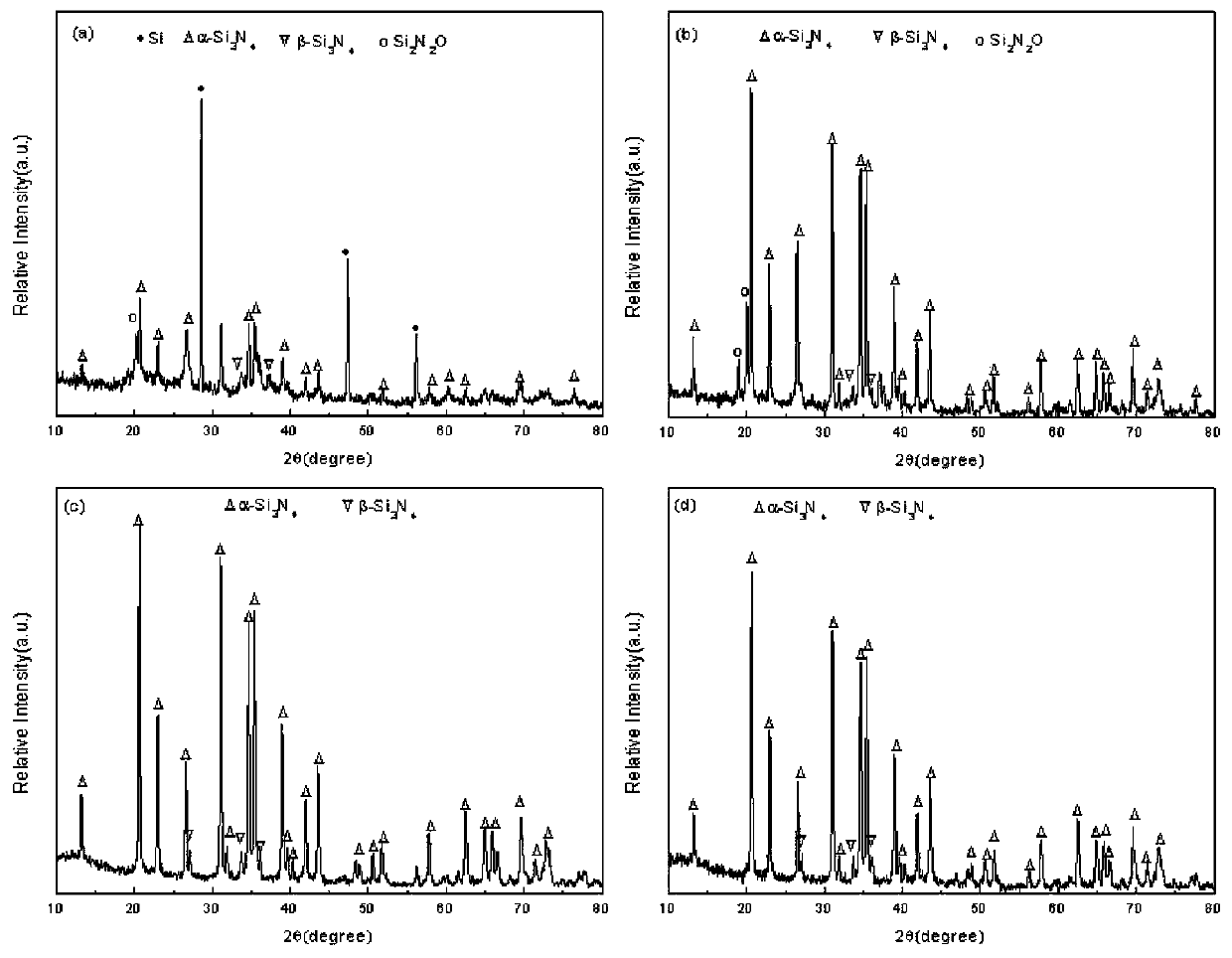

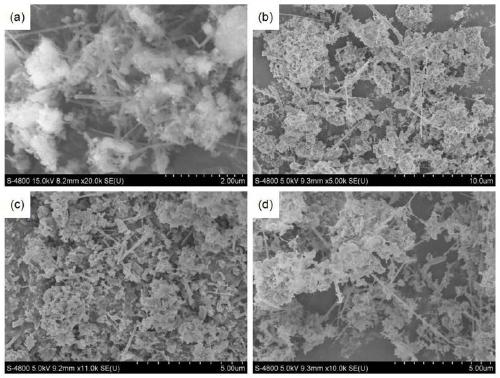

Embodiment 1

[0036] 1), Cr 2 o 3 Weigh the raw materials with Si powder according to the mass ratio of 2.5:97.5, and dope 2.5wt% Cr 2 o 3 The silicon powder of the powder is ball-milled, and the ball-milled powder is put into a silicon nitride ball mill tank, and silicon nitride balls and alcohol are added, wherein the powder: ball: alcohol mass ratio is 1:3:1.5. Put it into a planetary ball mill for ball milling, the rotating speed is 300r / min, and the ball milling time is 4h.

[0037] 2), the above ball milled doped 2.5wt% Cr 2 o 3 The silicon powder was suction filtered to remove the alcohol in the silicon powder; after that, the above filtered powder was dried in a vacuum drying oven to remove residual alcohol at a temperature of 40°C and a drying time of 4 hours. The above-mentioned vacuum-dried sample was ground and passed through a 40-mesh sieve to obtain a powder with uniform particles for subsequent nitriding experiments.

[0038] 3), the doped 2.5wt% Cr after above-mentione...

Embodiment 2

[0040] 1), Cr 2 o 3 Weigh the raw materials with Si powder according to the mass ratio of 2.5:97.5, and dope 2.5wt% Cr 2 o 3 The silicon powder of the powder is ball milled, and the ball milled powder is put into a silicon nitride ball mill tank, and silicon nitride balls and alcohol are added, wherein the powder: ball: alcohol mass ratio is 1:6:1.5. Put it into a planetary ball mill for ball milling, the rotating speed is 400r / min, and the ball milling time is 2h.

[0041]2), the above ball milled doped 2.5wt% Cr 2 o 3 The silicon powder was suction filtered to remove the alcohol in the silicon powder; after that, the above filtered powder was dried in a vacuum drying oven to remove residual alcohol at a temperature of 80°C and a drying time of 2 hours. The above-mentioned vacuum-dried sample was ground and passed through a 40-mesh sieve to obtain a powder with uniform particles for subsequent nitriding experiments.

[0042] 3), the doped 2.5wt% Cr after above-mentioned...

Embodiment 3

[0044] 1), Cr 2 o 3 Weigh the raw materials with Si powder according to the mass ratio of 2.5:97.5, and dope 2.5wt% Cr 2 o 3 The silicon powder of the powder is ball-milled, and the ball-milled powder is put into a silicon nitride ball mill tank, and silicon nitride balls and alcohol are added, wherein the powder: ball: alcohol mass ratio is 1:4:1.5. Put it into a planetary ball mill for ball milling, the rotating speed is 400r / min, and the ball milling time is 2h.

[0045] 2), the above ball milled doped 2.5wt% Cr 2 o 3 The silicon powder was suction filtered to remove the alcohol in the silicon powder; after that, the above filtered powder was dried in a vacuum drying oven to remove residual alcohol at a temperature of 80°C and a drying time of 2 hours. The above-mentioned vacuum-dried samples were ground and passed through a 70-mesh sieve to obtain a powder with uniform particles for subsequent nitriding experiments.

[0046] 3), the doped 2.5wt% Cr after above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com