Three-dimensional bionic bone repair material and preparation method thereof

A three-dimensional bionic bone and repair material technology, applied in the medical field, can solve the problems of difficult to realize the simple preparation of three-dimensional bionic fibrous bone repair materials, not having the oriented layered structure of simulated bone tissue, mechanical property defects, etc. Simple preparation process and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing a three-dimensional bionic bone repair material according to an embodiment of the present invention comprises the following steps:

[0047] S1: Uniformly disperse the bioactive glass fibers in the dopamine solution to form a suspension;

[0048] S2: Inject the suspension into a two-way freezing device to freeze, so that the suspension forms a coagulated body;

[0049] S3: removing the solidified solvent in the solidified body to obtain the three-dimensional bionic bone repair material.

[0050] Further, in order to prepare bone repair materials containing polylactic acid-coated bioactive glass fibers, the following steps are also included before step S1:

[0051] S1': After uniformly dispersing the bioactive glass fiber in the polylactic acid solution, drying and removing the solvent to obtain polylactic acid-coated bioactive glass fiber;

[0052] The resulting polylactic acid-coated bioactive glass fibers and / or uncoated bioactive glass fibers ...

Embodiment 1 3

[0056] Embodiment 1 Preparation of three-dimensional bionic bone repair material

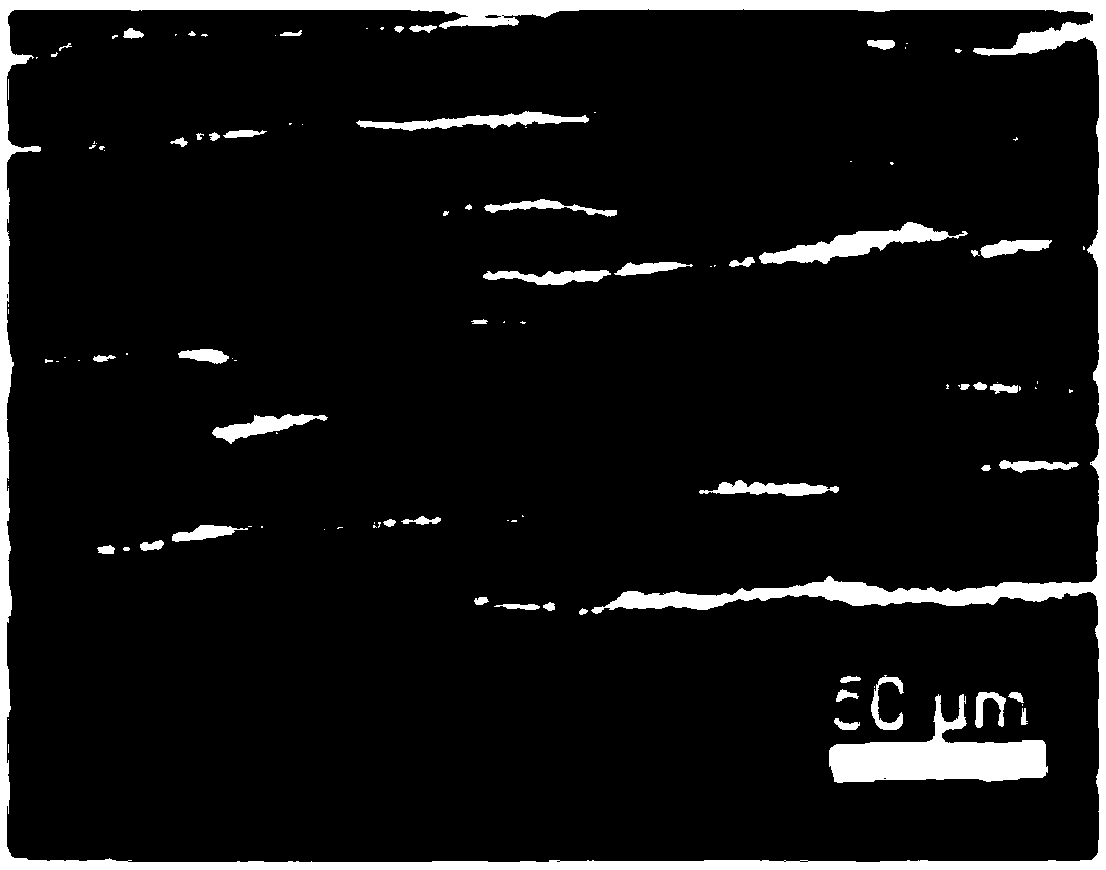

[0057] Add 1.5g of bioactive glass fiber to 100ml of a dopamine solution with a concentration of 5mg / ml, disperse it uniformly for 15 minutes with a homogenizer, stir the resulting dispersion at 300 rpm for 24 hours, and homogenize the obtained dispersion Inject the dispersion liquid into the two-way freezer, and freeze it in the two-way freezer, take it out after 15 minutes, put the obtained frozen sample into the freeze dryer, dry it for 24h at -50°C, and the vacuum degree is less than 20Pa, and then wash it with water to remove it. Unreacted dopamine and impurities were freeze-dried to obtain 1.52 g of three-dimensional bionic bone repair material. The volume density of the three-dimensional bionic bone repair material is 16mg / cm 3 , interlayer distance 20μm, porosity 90%.

Embodiment 2

[0058] Example 2 Preparation of polylactic acid composite three-dimensional bionic bone repair material

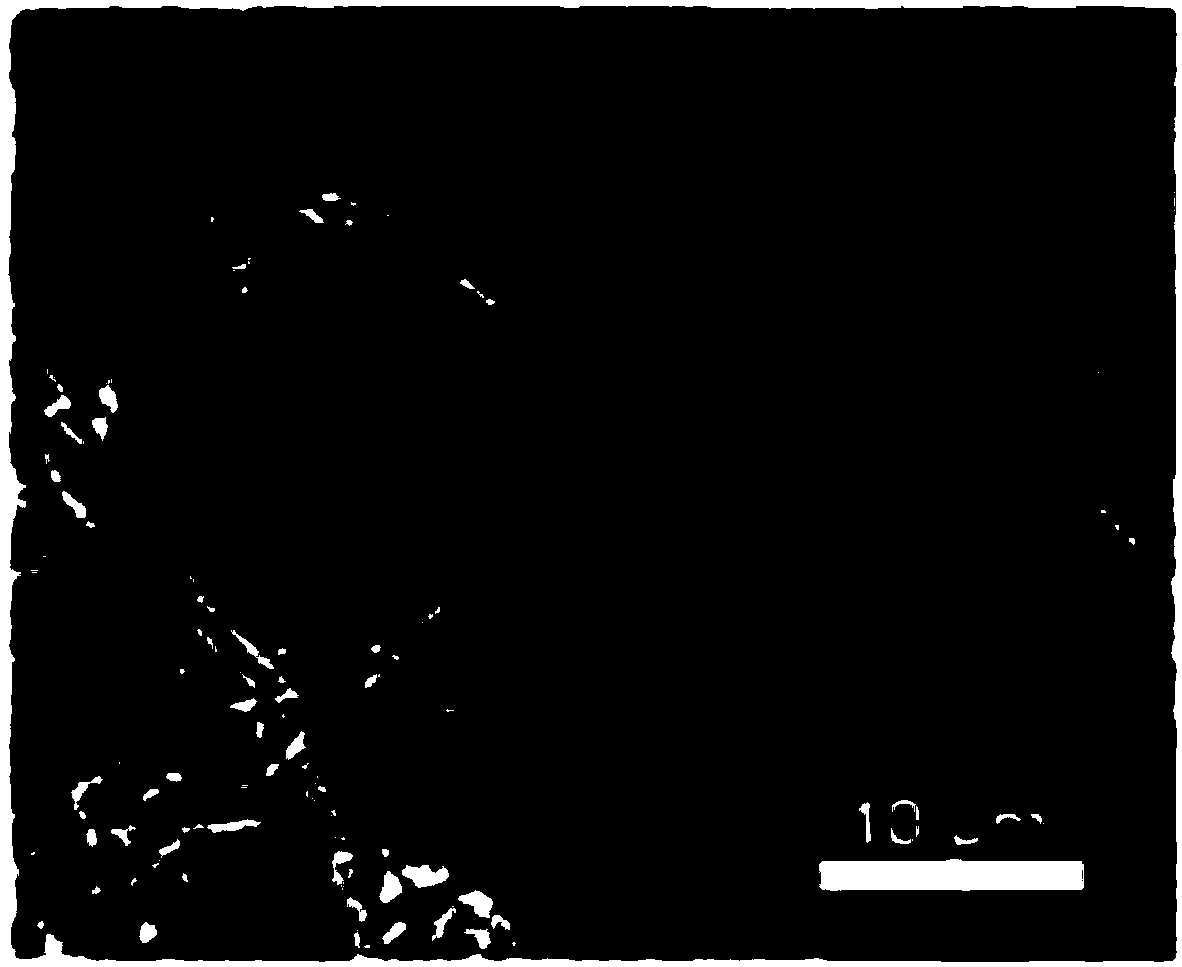

[0059] Dissolve 0.5g of polylactic acid in 100ml of chloroform solution, then add 2g of bioactive glass fiber, stir for 1 hour at 100 rpm, filter, and dry in an oven at 60°C for 10 hours to obtain polylactic acid Coated bioactive fiberglass. Add 1.5g of the above-mentioned fibers to 100ml of a dopamine solution with a concentration of 5mg / ml, disperse uniformly for 15 minutes with a homogenizer, stir the obtained dispersion at 300 rpm for 24 hours, and mix the obtained uniform dispersion Pour into the two-way freezer, freeze in the two-way freezer, take it out for 15 minutes, put the obtained frozen sample in a freeze dryer, dry it for 24 hours at -50°C, and vacuum less than 20Pa, then wash it with water to remove unreacted Dopamine and impurities in the mixture were freeze-dried to obtain 1.52 g of three-dimensional bionic bone repair material. The polylactic acid compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com