High-oil-content facial cleanser and preparation method thereof

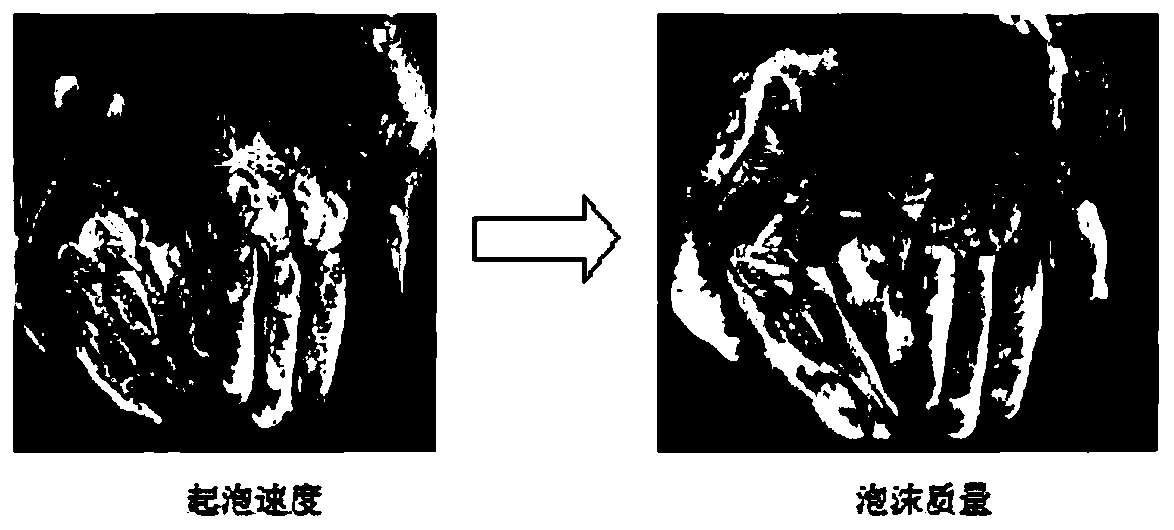

A technology of oil content and facial cleanser, which is applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc. It can solve the problems of insufficient foam, slow foaming speed, skin irritation, etc., and achieve rich and fine foam and refreshing skin surface Smooth, strong cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A high oil content facial cleanser made from the following components in parts by weight: 10 parts lauric acid, 5 parts myristic acid, 5 parts palmitic acid, 20 parts olive oil, 10 parts glycerin, 10 parts acrylates / Beheneth-25 Methacrylate Copolymer, 2 Parts Glyceryl Stearate, 4.6 Parts Potassium Hydroxide, 0.05 Part EDTA-Disodium, 1 Part Polyquaternium 22, 0.2 Part Preservative and 15 portion of water;

[0048] The method for preparing the facial cleanser with high oil content comprises the following steps:

[0049] S1: Clean the equipment including the reactor with 90°C sterilized water, then rinse with 75% disinfectant alcohol, and dry with cold air;

[0050] S2: Add EDTA-disodium into the reactor, add water to heat to dissolve, add acrylate / beheneth-25 methacrylate copolymer, stir and mix;

[0051] S3: Add glycerin and fatty acid and stir evenly, add sodium hydroxide, stir and heat at 20 rpm to 85°C and keep stirring for half an hour, then add glyceryl stearate...

Embodiment 2

[0054] A high oil content facial cleanser made from the following components in parts by weight: 10 parts lauric acid, 5 parts myristic acid, 5 parts palmitic acid, 30 parts olive oil, 10 parts glycerin, 10 parts acrylates / Beheneth-25 Methacrylate Copolymer, 2 Parts Glyceryl Stearate, 4.6 Parts Potassium Hydroxide, 0.05 Part EDTA-Disodium, 1 Part Polyquaternium 22, 0.2 Part Preservative and 20 portion of water;

[0055] The method for preparing the facial cleanser with high oil content comprises the following steps:

[0056] S1: Clean the instruments including the reactor with 100°C sterilized water, then rinse with 75% disinfectant alcohol, and dry with cold air;

[0057] S2: Add EDTA-disodium into the reactor, add water to heat to dissolve, add acrylate / beheneth-25 methacrylate copolymer, stir and mix;

[0058] S3: Add glycerin and fatty acid and stir evenly, add sodium hydroxide, stir and heat at 10 rpm to 90°C and keep stirring for half an hour, then add glyceryl stear...

Embodiment 3

[0061] A high oil content facial cleanser made from the following components in parts by weight: 10 parts lauric acid, 5 parts myristic acid, 5 parts palmitic acid, 25 parts mineral oil, 10 parts glycerin, 10 parts acrylates / Beheneth-25 Methacrylate Copolymer, 2 Parts Glyceryl Stearate, 4.6 Parts Potassium Hydroxide, 0.05 Part EDTA-Disodium, 1 Part Polyquaternium 22, 0.2 Part Preservative and 25 portion of water;

[0062] The method for preparing the facial cleanser with high oil content comprises the following steps:

[0063] S1: Clean the instruments including the reactor with 100°C sterilized water, then rinse with 75% disinfectant alcohol, and dry with cold air;

[0064] S2: Add EDTA-disodium into the reactor, add water to heat to dissolve, add acrylate / beheneth-25 methacrylate copolymer, stir and mix;

[0065] S3: Add glycerin and fatty acid and stir evenly, add sodium hydroxide, stir and heat at 30rpm to 80°C and keep stirring for half an hour, then add glyceryl stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com