Intelligent weeding gapper in small shed and use method

A small arch shed, intelligent technology, applied in the fields of thinning machinery, application, soil preparation machinery, etc., can solve the problems of time-consuming, labor-intensive, and vegetable seedling damage by manual weeding and thinning, and achieves improved automation and intelligence. Level, reduce labor Strength, the effect of achieving precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

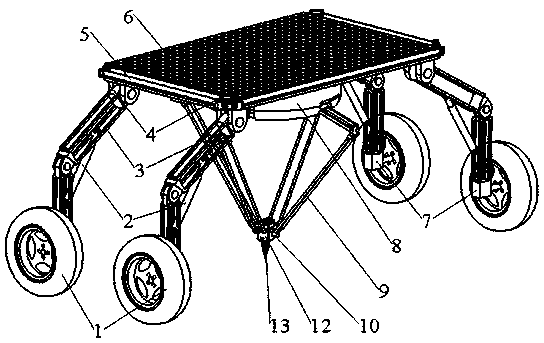

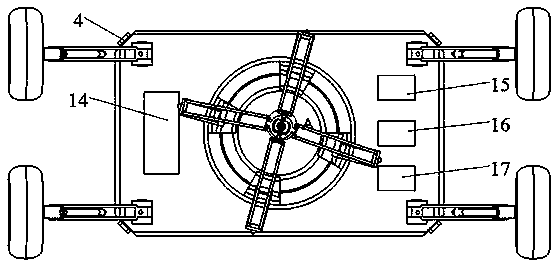

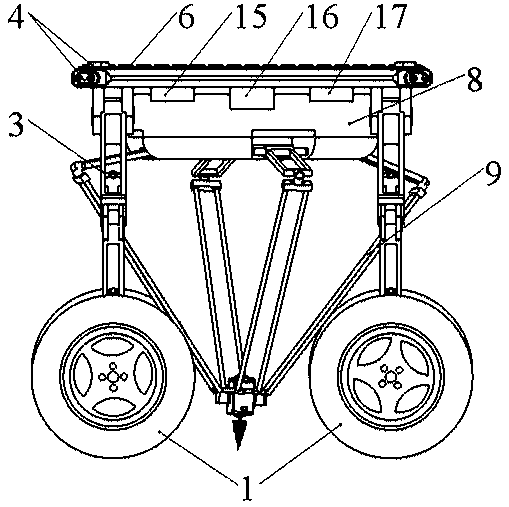

[0028] like figure 1 A kind of intelligent weeding and seedling thinning machine inside a small arch shed is shown, including a mobile platform 5 equipped with a walking device, and a main switch 15, a main controller 16 and a mechanical arm device installed on the mobile platform 5, the main switch 15, the main control The device 16 and the mechanical arm device are all located below the mobile platform. The front and upper ends of the four corners of the mobile platform 5 are respectively equipped with infrared obstacle avoidance sensors 4 electrically connected to the master controller. The device is mainly composed of a decoder.

[0029] The mechanical arm device includes a mechanical arm base 8 fixed on the bottom surface of the mobile platform and a parallel three-degree-of-freedom delta mechanical arm 9 installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com