Pin used on component

A technology of components and pins, applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of floating height and virtual soldering of pins, reduce thickness, increase contact area, and solve the problem of virtual soldering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

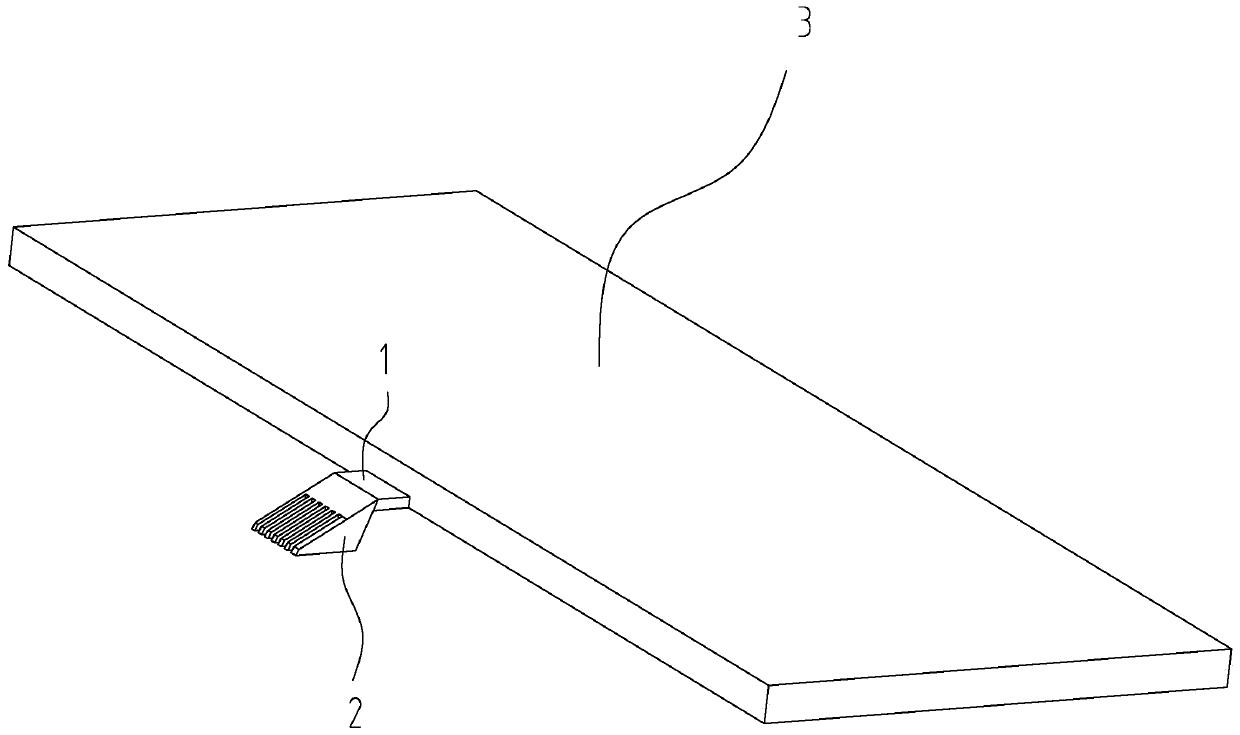

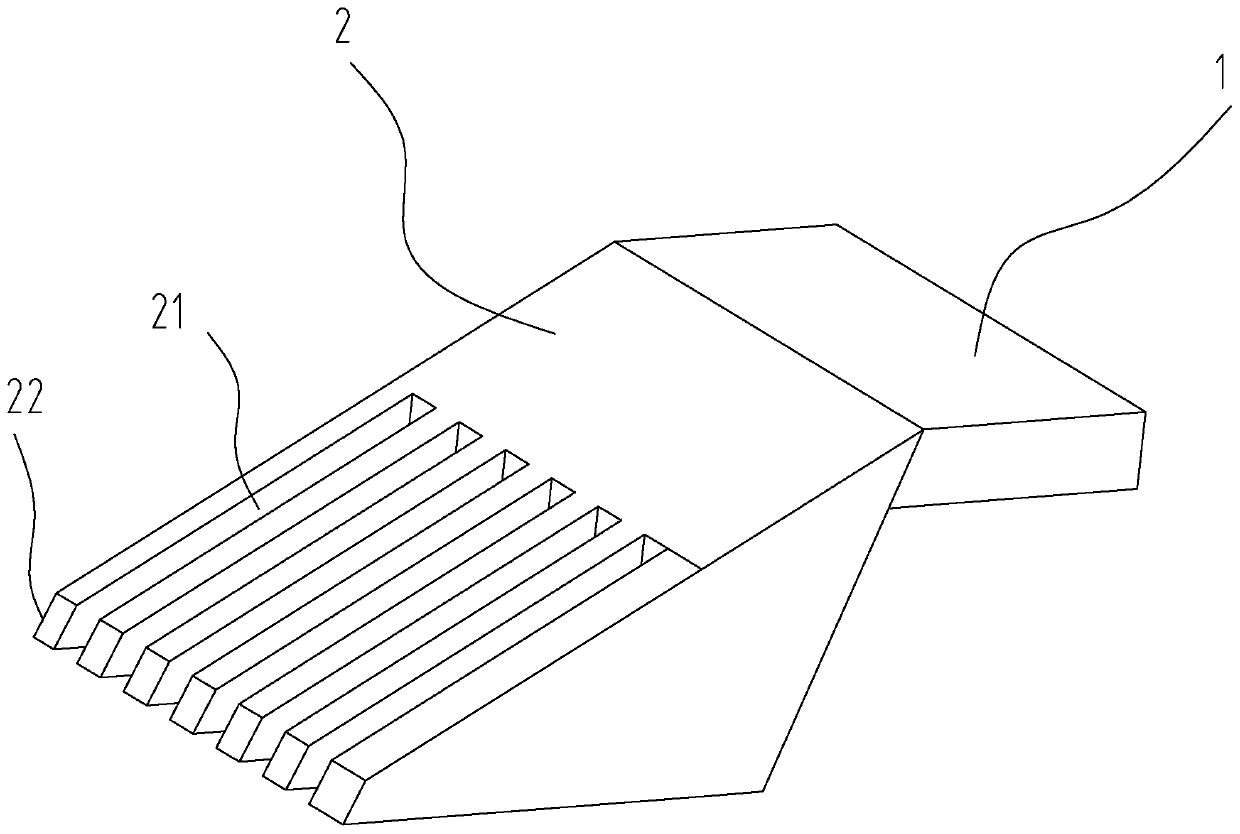

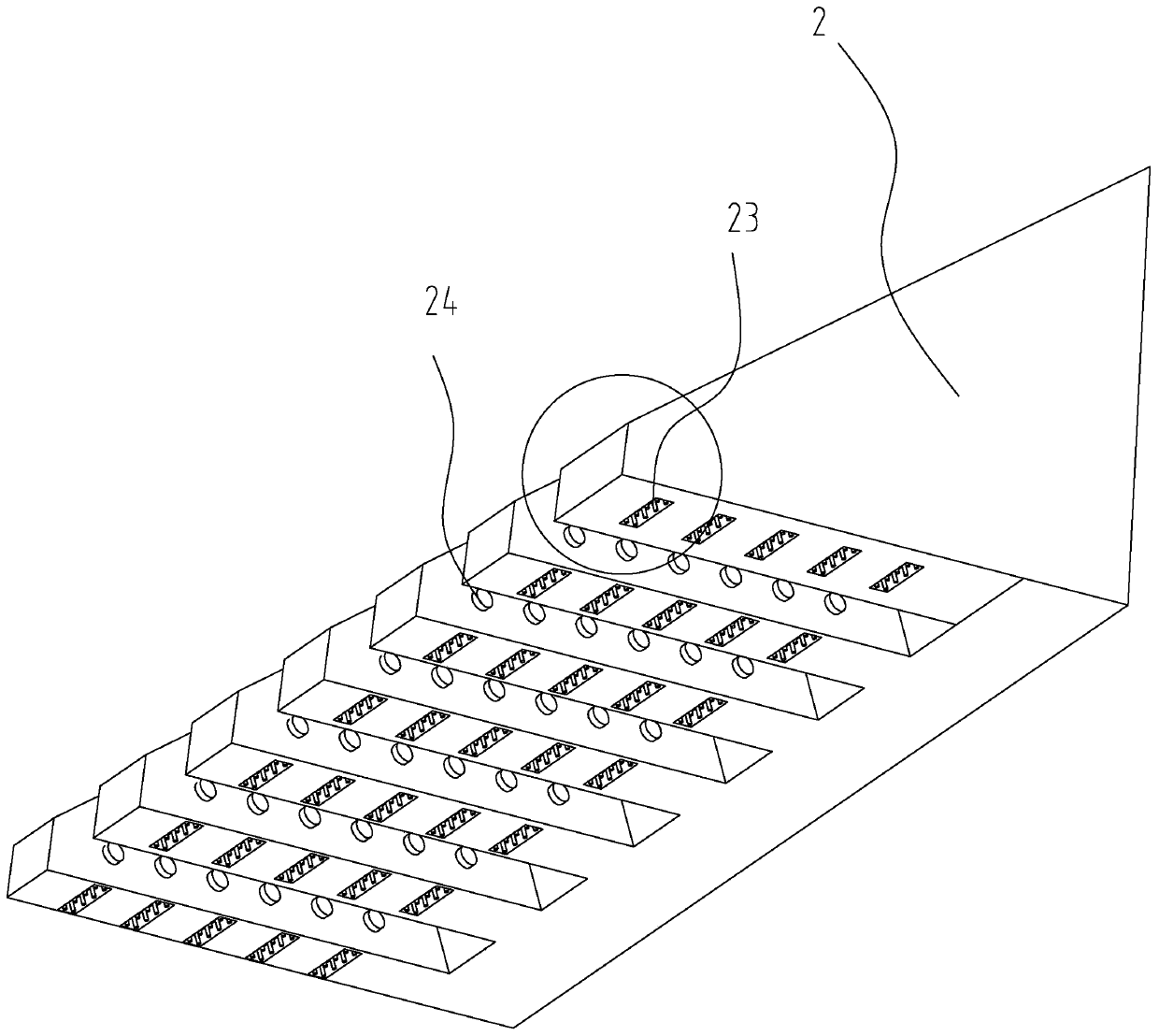

[0022] In order to clearly illustrate the technical characteristics of this program, the following specific implementation methods, combined with its attached Figures 1 to 4 , the present invention is described in detail. It should be noted that components illustrated in the figures are not necessarily drawn to scale. The present invention omits descriptions of well-known components and well-known technologies in order to avoid unnecessarily limiting the present invention.

[0023] A pin used for components, including a pin connection plate 1 and a pin bottom plate 2; the left end surface of the pin connection plate 1 is fixed with a pin bottom plate 2, and the left end of the pin bottom plate 2 is a climbing slope 22 , the climbing slope 22 is an inclined surface provided upwardly from the bottom surface of the pin base plate 2, and the pin base plate 2 is provided with a plurality of parallel solder paste retention grooves 21, and the solder paste retention grooves 21 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com