Water-based adhesive for automotive interior as well as preparation method and application of adhesive

A technology for automotive interiors and adhesives, applied in adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve problems such as not describing the pre-coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

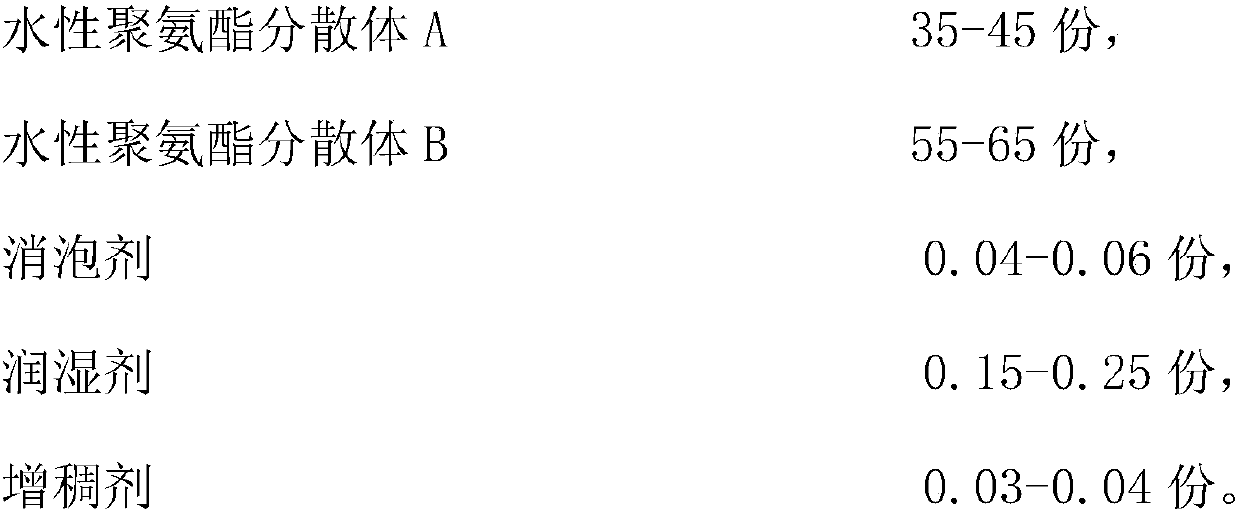

[0054] A kind of water-based automotive interior adhesive is made up of the following components by weight:

[0055]

[0056] The raw materials used in embodiment 1 are as follows, aqueous polyurethane dispersion (Raw material composition: hexamethylene diisocyanate, 4,4'-dicyclohexylmethane diisocyanate, polybutylene adipate, N-(2-aminoethyl)-2-aminoethanesulfonate ): solid content of 50±1wt.%, Wanhua Chemical Group Co., Ltd.; aqueous polyurethane dispersion (Raw material composition: hexamethylene diisocyanate, polybutylene adipate, polyester diol composed of 1,6-hexanediol, neopentyl glycol and adipic acid, sulfonate type hydrophilic Hydrate, N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane): solid content of 50±1wt.%, Wanhua Chemical Group Co., Ltd.; defoamer BYK-024: Qingdao Hua Ling Chemical Products Co., Ltd.; wetting agent TEGO-KL245: Nanjing Hanbao Industrial Raw Materials Co., Ltd.; thickener Wanhua Chemical Group Co., Ltd.

[0057] The pre-coating process of...

Embodiment 2

[0090] A kind of water-based automotive interior adhesive for pre-coating process is made up of the following components by weight:

[0091]

[0092] In this example, defoamer BYK-022 and wetting agent BYK-349: Qingdao Hualing Chemical Products Co., Ltd.; thickener Wanhua Chemical Group Co., Ltd.

[0093] Aqueous polyurethane dispersion B preparation:

[0094] 150g of dehydrated polyadipate-1,4-butylene glycol ester diol (OH value=56mg KOH / g), 60g of dehydrated 1,6-hexanediol, neopentyl glycol and hexane The polyester diol (OH value=74mg KOH / g) that diacid forms, 28.5g hexamethylene diisocyanate, 3.15g the monofunctional polyethoxy ether (average molecular weight 520g / mol, MPEG520) of dehydration treatment , LG Chemical), 24g of acetone into a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 80° C. until NCO reached a theoretical value of 1.63%. The prepolymer was dissolved in 405 g of acetone and cooled to 50...

Embodiment 3

[0116] A kind of water-based automotive interior adhesive for pre-coating process is made up of the following components by weight:

[0117]

[0118] In this example, the aqueous polyurethane dispersion Covestro; defoamer BYK-020: Qingdao Hualing Chemical Products Co., Ltd.; wetting agent TEGO-KL245: Nanjing Hanbao Industrial Raw Materials Co., Ltd.; thickener Wanhua Chemical Group Co., Ltd.

[0119] Aqueous polyurethane dispersion B preparation:

[0120]120g of dehydrated polyadipate-1,4-butylene glycol ester diol (OH value=56mg KOH / g), 40g of dehydrated 1,6-hexanediol, neopentyl glycol and hexane Polyester diol composed of diacid (OH value=74mg KOH / g), 10g dehydrated polyadipate-1,4-butylene glycol ester diol (OH value=112mgKOH / g), 18.35g six Methylene diisocyanate, a mixture of 10g 4,4'-dicyclohexylmethane diisocyanate, 2g dehydration-treated monofunctional polyethoxy ether (average molecular weight 1200g / mol, MPEG1200, LG Chemical), 25g Acetone was added into a 1L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com