Hot-stamping process for tank body of metal circular tank

A metal can and can body technology, which is applied in the field of metal can preparation technology, can solve the problems of being unsuitable for the production of small special can bodies, reducing the production speed of standard cans, unable to produce round cans, etc., and achieves convenient bronzing processing and convenient bronzing. Craftsmanship, the effect of enhancing beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] The invention provides a bronzing process for the can body of a metal round can. On the basis of the traditional bronzing process, the can body of the metal round can is gilded, so that the gilding process can be performed on the can body, thereby enhancing the aesthetic feeling of the can body. Improve tank recognition.

[0027] As an embodiment of the present invention, the present invention provides a bronzing process for the can body of a metal round can, and the specific steps are as follows:

[0028] 1) After the metal can is rounded, it enters the equipment vertically and automatically, is grabbed by mechanical claws and placed flat, and enters the processing station of the equipment;

[0029] 2) Bake the surface of the metal can body;

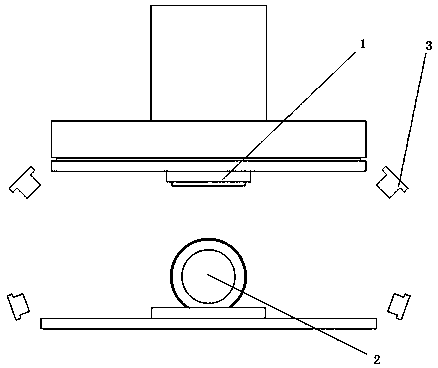

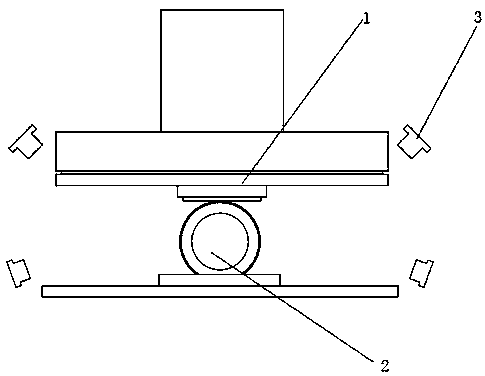

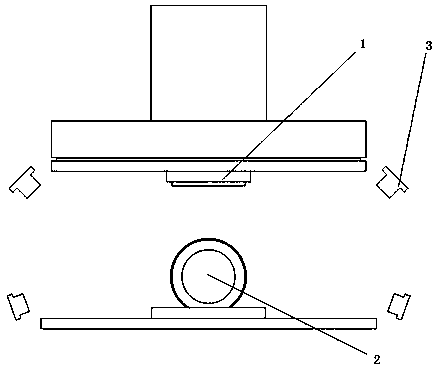

[0030] 3) Through the upper and lower cameras 3, the visual positioning is carried out throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com